Respirator inspection is critical to maintaining safe working conditions. Depending on the atmospheric conditions, it could mean the difference between life and death. Due to the severity of the consequences of inaction, we’ve decided to help you with a handy respirator inspection guide and downloadable respirator inspection checklist.

The respirator inspection checklist is a crucial tool for anyone who requires the use of a respirator. Respirator inspection ensures that the equipment is working correctly and in good working order and that the cartridges are appropriate for the conditions.

We’ll examine the different aspects of respirator inspection and provide helpful tips for easier respirator management. If you stick around to the end, we’ve got some secret tips to make your entire inspection process much easier and more efficient. But we’ll discuss how to stop the inefficiencies in your inspection process later.

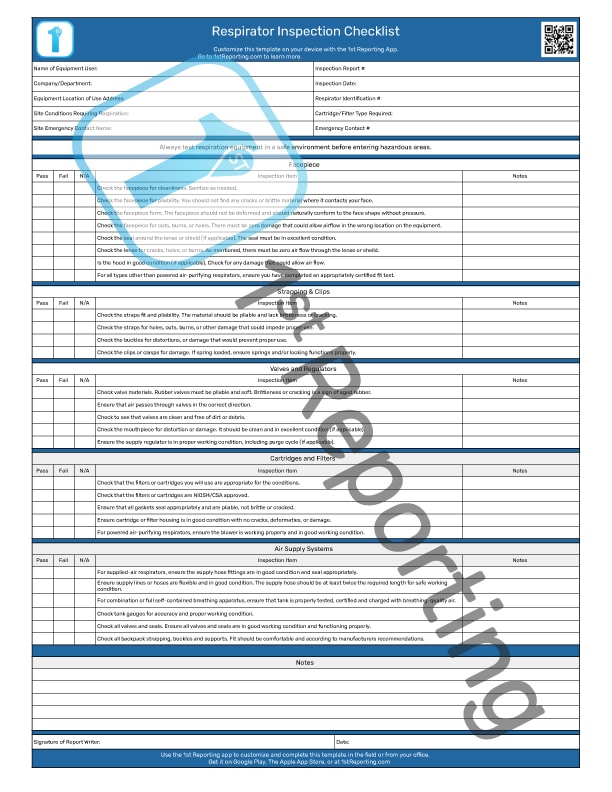

Included in the Respirator Inspection Checklist

There are multiple different types and configurations of respiration equipment. We’ve broken down the inspection process into seven stages, covering everything from a simple face mask to an SCBA (self-contained breathing apparatus).

- Administrative Management – The administrative management stage of the inspection requires that the user have an appropriate respirator system on hand. The assessment should start with documenting the user’s name and equipment identification, and ideally, it should include the location and hazard.

- Facepiece Inspection—The physical inspection begins with the facepiece’s main body of the respirator equipment. The checklist notes various considerations regarding this part of the equipment.

- Strapping and Clips—Strapping and clips are essential to the respirator’s ability to hold the facepiece securely against the face. Straps that are weathered, aged, or damaged might present a variety of symptoms, as noted on the inspection checklist.

- Valves and Regulators—Valves keep the direction of airflow under control. They prevent the air from building up to unsafe levels while maintaining positive air pressure. Valves are present in all but the simplest face masks.

Regulators are a standard part of closed-air respiration systems and even some powered air-purifying respirators. Given the conditions in which these pieces of equipment work, it’s vital to ensure proper inspection and testing of the regulators, valves, and similar parts of the equipment.

- Cartridges and Filters – Cartridges and filters make breathing possible in hazardous environments. Selecting new and functional cartridges and filters is crucial to ensure team member safety. This section includes the preliminary questions one should ask before using respiratory equipment.

- Air Supply Systems—Some of the most special-cased and less common respirators use either an enclosed or filtered/supplied air supply. Examples of these types of systems are supplied air respirators, self-contained breathing apparatus (SCBAs), powered air-purifying respirators (PAPRs), or combination respirators used in IDLH environments.

Given these respirators’ unique nature and design, it is critical that your team performs thorough daily inspections and required maintenance before using the equipment. We recommend a daily pre-use program for effective and safe operations.

- Notes and Sign-Off—The final stage of a proper inspection includes adding any remaining notes worth communicating on the inspection report. Finally, the user signs off on the validity of the inspection report—a means to ensure they do their best.

Each stage has a corresponding section on the checklist. Now that we’ve gone over the checklist fundamentals, we’ll provide some great tips below. These tips will help you create an efficient and effective workflow for your team’s inspections and save you time and money. Let’s dive in.

How To Use The Checklist For A Better Respirator Inspection Process

Frequency

We mentioned that a daily pre-use inspection is vital to strategically manage respirators and similar breathing personal protective equipment. So, that involves frequency. We might also suggest adding a closing schedule for the equipment involving a wipe-down and disinfection. Our checklist works perfectly for both pre and post-work inspections for respirators.

Training and Refresher Training

One of the best ways to ensure your team’s safety is to ensure proper training. Elements like how to don and doff a respirator, identify hazards, and what kind of filters to use in different scenarios are all essential. Furthermore, it’s not only about the initial training—refresher training is critical.

The checklist can be a valuable guide for your team members’ initial training and refresher courses. Speaking of training, do you know all the different types of PPE you need to manage for your team? Take a look at our PPE Guide for Managers for more information.

Communication

Clear communication is critical for maintaining safety in any workplace but is even more crucial when dealing with hazardous materials. Communicating to ensure everyone on your team knows about the inspection process thoroughly. Moreover, ensure that everyone can access the most updated inspection checklist version.

Encourage communication within your team. Never make a team member feel afraid to report a defect or concern about their respirator. It would help if you also had a reporting system in place so that your team could quickly rectify any defects found during the inspection.

Encourage Good Penmanship

When team members’ reports rely on their ability to perceive and record data, they must be legible. You can encourage good penmanship by outwardly rewarding those who provide neat and professional checklists and reports. Promoting their professionalism is one way to indirectly encourage other team players to excel and also provide neat and legible reports.

Setup A Media Database

They say a picture speaks a thousand words, which I believe is true regarding inspections. There is nothing better than taking a photo or video to explain a concern with equipment. However, a paper-printed checklist isn’t the best solution if you want to include pictures and videos.

To encourage media collection during inspections, try creating a media database and showcasing previous media as professionals. Some advice is to manage similarly to promoting good penmanship and good media collection (without sacrificing their regular work routine).

How To Add More Value To Your Inspection Processes and Ensure Perfection Every Time

If you want to improve your team’s inspections and reporting, you need to graduate from the school of paper and enroll in your company’s future—digital inspection reporting.

Imagine you have a platform that works on all your team’s smartphones, tablets, laptops, and desktop computers. Your team could access a respirator inspection checklist customized and branded for your company right on their phone.

They could also access any number of other checklists or reports in our robust template library, built right into the app.

How much would a digital report that uses clean fonts instead of your team member’s messy handwriting be worth to you? I can tell you that it would be worth it just from the savings in paper and printing fees alone.

We’ve developed the exact tool we’re talking about, and our honest and transparent pricing ensures you can quickly see how much time and money you’ll save managing inspection reports once you implement our digital reporting solution.

Do you work with Microsoft Teams®? Our mobile form application, 1st Reporting, is integrated with the Teams® environment, so you can receive custom notifications when a team member completes a report—right inside your Teams® dashboard! It’s even easier to share reports and data with our cloud-based secure reporting solution.