Using an Energized Electrical Work Permit is necessary whenever a situation arises where qualified personnel must perform duties that bring them into potentially dangerous proximity to electrically powered, live equipment. Although the goal is always to de-energize equipment, there are circumstances where required work requires a live source. For example, when measuring voltage or amperage within a system.

Our Energized Electrical Work Permit is found in both a digital download that you can print and use and a digital template within our 1st Reporting application. The application enables you to customize the template and provide it digitally to your team. In turn, your selected team can use the application to document observations and complete reports right on their smart device.

In this guide, we’ll review what’s included in the Energized Electrical Work Permit and provide a standardized process for best practices using the template. We’ll also look at how digital reporting and the use of digital templates can help your team work safer and more efficiently than ever before.

Included in the Energized Electrical Work Permit

The energized electrical work permit has eight primary components. Let’s review the components and describe their intended use to ensure all stakeholders are on the same page. We recommend adding a bookmark to this page and sharing the guide with your team so everyone is on the same page. Below is a brief overview of each of the template’s sections.

Administrative Information

The administrative section of the Energized Electrical Work Permit includes vital information, including the names of the qualified person doing the work as well as the name of the project approving manager. Further details in the section include the facility name, address, location of work, the name of the safety contacts on-site, permit date, work start and end times and equipment identifier, energy feed source, and a space to note attached reports or documents.

For our downloadable PDF template, you might want to include images that you’ll need to print and label accordingly. These sorts of media are more difficult to enter into hardcopies due to the need for a camera and color printer. However, if you’re using our 1st Reporting application for your field report needs, you’ll find it easy to upload images and even videos to the report itself. I’ll talk more about that later.

Reason For Energized Work Request

One of, if not the most essential factors, is why work must occur on live equipment. Why can’t the live equipment be de-energized so work can occur safely? We’ve included two blank rows for a simple and concise reason input.

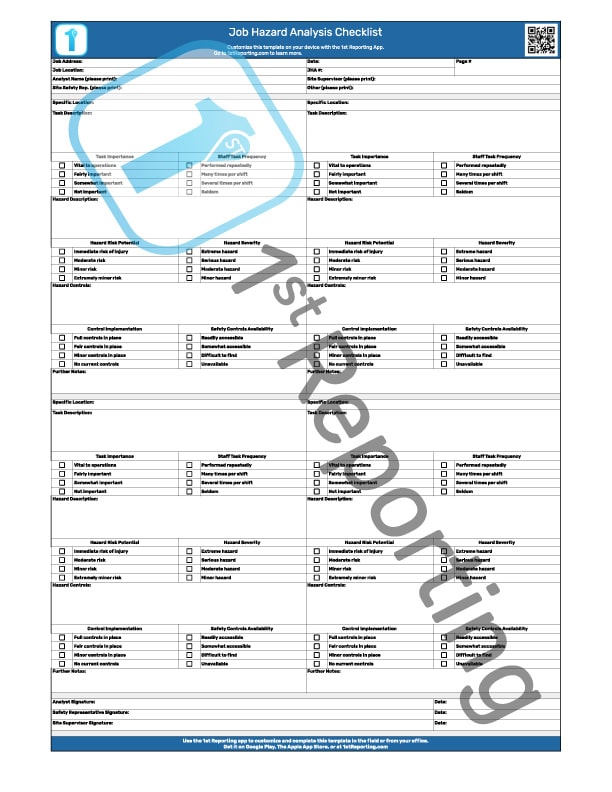

Hazard Analysis

Electricity is a serious hazard that poses a life and death risk. Therefore, a hazard analysis must occur, and this is likely the most essential aspect of completing an energized electrical work permit. Understanding the risks involved is the only way to prevent injury or worse from events like Arc Flash.

Electrical Source Information

The hazard analysis begins with identifying sources of electrical energy and noting their quantities. Furthermore, the amount of energy determines our safe working distance and thus safe work practices, so it’s critical information.

Worksite Access Information

Sometimes work requires accessing unusual areas like confined spaces or above suspended ceilings. Noting the site conditions enables us to determine the proper types and use of personal protective equipment or PPE.

Observable Hazards Present

A significant aspect of the hazard analysis process is the determination of which hazards are present. We already know about the electrical hazard, but what about other dangers? For example, you might need to work near live equipment or vehicle traffic, near chemicals, or in a confined space where atmospheric hazards might also present themselves.

Description of Required Work

In order to properly manage how a job must transpire and the timeframe for the project, we must understand the requirements of the work. Therefore, permit creators must comprehensively describe the work requirements in this section.

Special Instructions

Further to the customized situation, some special instructions might be required for safe work completion. These special instructions might include access steps, or climate-specific instructions, for example.

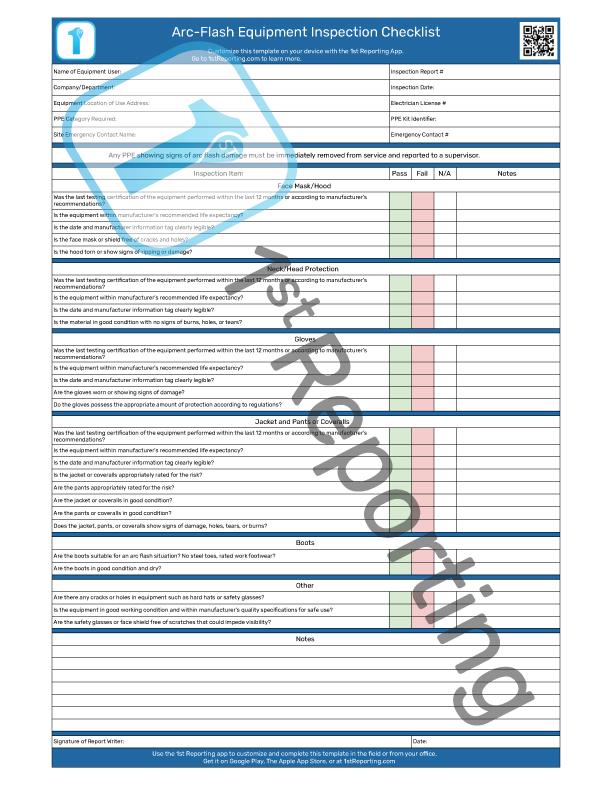

PPE Requirements

We’ve documented hazards, and now it’s time to document the project’s required personal protective equipment. The equipment choices should reflect the nature and severity of the risk and act to prevent injury in the worst of scenarios.

Approach Boundaries – Reference NFPA 70E, Table 130.2(C)

With the proper voltages noted, we can use some simple math to calculate the appropriate boundaries. Luckily, this is already done for us using the NFPA-provided table found on our template:

| System Voltage | Limited Approach Boundary | Restricted Approach Boundary | Prohibited Approach Boundary | ||

| < 50V | not specified | not specified | not specified | ||

| 50V to 300V | 3’ 6” * | avoid contact | avoid contact | ||

| 301V to 750V | 3’ 6” * | 1’ 0” | 0’ 1” | ||

| 751V to 15 kV | 5’ 0” * | 2’ 2” | 0’ 7” | ||

| 5.1kV to 35kV | 6’ 0” * | 2’ 7” | 0’ 10” | ||

| 36.1kV to 46kV | 8’ 0” * | 2’ 9” | 1’ 5” | ||

| 46.1kV to 72.5kV | 8’ 0” * | 3’ 2” | 2’ 1” | ||

| 72.6kV to 121kV | 8’ 0” ** | 3’ 3” | 2’ 8” | ||

| 138kV to 145kV | 10’ 0” * | 3’ 7” | 3’ 1” | ||

| * The limited approach distance is 10’ if moveable conductors exist. | ** The limited approach distance is 10′ 8″ if moveable conductors exist. | *** The limited approach distance is 11′ 0″ if moveable conductors exist. | |||

Determination of approach boundaries is critical to worker risk mitigation and prevention. Furthermore, it provides a boundary to measure to keep pedestrians and passers-by at extended minimum safe distances.

Flash Hazard Analysis – Reference NFPA 70E.130.3(A)

Following NFPA 70E.130.3(A), we have included a flash hazard analysis section to the Energized Electrical Work Permit. This section is critical for summing up the overall risk and noting the fault-clearing device information as needed.

Risk Level Severity

The risk severity metric allows report writers to note the overall risk of hazard relative to the severity of a potential accident. Furthermore, this section of the template also enables us to include the methods for controlling the risks, the name of the safety watch person, the means of emergency communication, and the date on which the permit will expire.

Project Stage Completion & Sign-Off

According to regulations, the rule is to plan and create a hazard analysis any time energized electrical work requirements arise. Further to the analysis, you need to host a job briefing with all stakeholders so risks and hazard communication occurs prior to the job starting—this process further aids project safety by allowing for discussion of critical aspects of job safety.

Lastly, the template includes a place for two dated signatures, one for the project lead completing the work and one for the authorizing manager approving the work permit request.

How To Use the Energized Electrical Work Permit

The use of the Energized Electrical Work Permit (EEWP) is straightforward. The template follows best practices for OSHA and NFPA 70E regulations for electrical work. Here’s a brief rundown of best practices for use.

Digital Download (PDF) EEWP

- Download our Energized Electrical Work Permit.

- Print as many copies as you and your team will need.

- Set a meeting to train stakeholders on using and completing the EEWP.

- Note in your schedule to review EEWP use every six months to a year with your team members.

Digital EEWP (App Enabled)

- Sign up for the 1st Reporting app from this page, Google Play, or The Apple App Store.

- Invite your team members to download and install the app on their smart devices. The app works great on mobile devices like Android and iOS smartphones and tablets, on laptops, or on desktop computers. The app even has customization for notifications that even work inside the Microsoft Teams® environment.

- Use one of our (over 100) built-in templates, customize one of the templates, or create your own from scratch using the powerful form builder right in your app’s dashboard.

- Disseminate your new or customized templates to your team for instant use.

- Train your team on your preferred templates and best practices according to your operations.

That’s it! Simple, right? Now, within the app, you can use the powerful GPS-enabled management dashboard to see your reports on a map view of your choice. Furthermore, using the app’s powerful features, you can run reports to gain insights into trends within your reporting. Find out how the app can exponentially save your team time and money with the future of reporting: Digital reporting using the industry-standard, 1st Reporting app.

Final Thoughts on Effective and Efficient Work Permit Completion

The Energized Electrical Work Permit is crucial for ensuring worker safety while dealing with electrically powered, live equipment. The permit is divided into various sections designed to capture all necessary details such as administrative information, reasons for energized work, hazard analysis, electrical source, site conditions, observable hazards, required work, special instructions, PPE requirements, approach boundaries, flash hazard analysis, risk level severity, and project completion sign-offs.

Utilizing the permit, either as a downloadable PDF or through our interactive 1st Reporting app, is a systematic way to comprehensively cover all areas of safety while working with energized equipment. Regular training and updates are recommended to ensure that all stakeholders understand the use and importance of this document.

Emphasis should be placed on risk assessment and hazard mitigation. Determining the approach boundaries and flash hazard analysis is critical in defining the parameters of the work area, and the risk level severity metric assists in understanding the overall risk related to the job.

Moreover, the digital version of the permit within our 1st Reporting app optimizes safety procedures by enabling on-the-go permit customization and instant report dissemination, coupled with GPS-enabled management and the ability to extract insights from your reporting data.

In conclusion, effective and efficient completion of the Energized Electrical Work Permit is a robust approach to maintaining a safe and efficient workplace while dealing with live electrical equipment. This methodical and precautionary procedure is designed to prevent hazardous occurrences and protect the workforce, thereby ensuring project success in the face of potential risks.

Are you ready to set your reporting on a digital course for effective and more efficient field reporting? Try 1st Reporting today and find out what everyone’s talking about.