Regarding aerial lift safety, there is no room for mistakes. A proper aerial lift safety checklist can help minimize the chances of an accident happening.

This article will present a truly comprehensive aerial lift safety checklist for those who operate boom lifts. It will also describe the importance of following this checklist and detail some of the best practices you should follow.

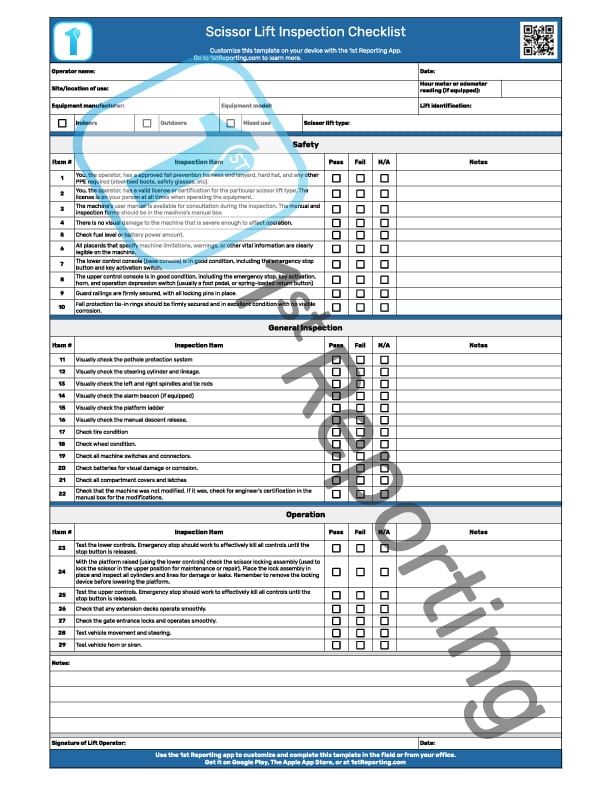

If you’re looking for a scissor lift inspection checklist, check out our specific-case template here or scissor lift certification information here. Otherwise, let’s dive into boom operators’ aerial lift safety checklist.

Our template on this page applies specifically to boom lifts.

What is an Aerial Lift Safety Checklist, And Which Equipment Applies?

An aerial lift safety checklist is a document that outlines the specific safety procedures that operators must follow when inspecting aerial lift equipment. In this case, we are referring to boom lifts which include both articulating and non-articulating booms.

The purpose of the aerial lift safety checklist is to ensure that all operators are aware of the necessary precautions to take before and while using aerial lifts, to keep themselves and those around them safe.

The aerial lift safety checklist would apply to any piece of aerial lift equipment, such as a boom lift or scissor lift (in most cases). However, the two must remain separated due to the different natures and operation of scissor lift equipment versus boom-lift equipment. As much as we’d like to lump the two together, they have some very different characteristics of note and different operational and safety considerations.

Included In The Aerial Lift Safety Checklist For Boom Lifts

Understanding Your Equipment Inspection: The Boom Lift Best Practises

There are four critical elements to safely using your equipment. Often overlooked, these elements, or at least one of these elements, are skipped altogether.

Some ‘comprehensive’ checklists out there don’t even mention some of these essential items. If you want your team to operate efficiently and with greater safety, then 1st Reporting has the only professional solutions for you and your team. Let’s take a look at those four critical elements now.

Pre-Use Inspections

Before using an aerial boom lift, it is essential to perform a pre-use inspection of the worksite and also the equipment. Never hesitate to check the weather, too; it can greatly affect outdoor site conditions.

Inspecting the equipment for any damage or defects and checking the fluid levels and electrical systems are critical before use. It is also critical to ensure that all of the safety features on the aerial lift are in proper working order. Remember that a boom lift can become entangled in some fairly complicated positions and places, so ensure rescue plans and emergency features are both in place and fully operational.

Operators should be familiar with the aerial lift they are using and know how to operate it safely. Ideally, the operator possesses a legitimate certification for use. In some areas, certification is mandatory. They should also be aware of the weight capacity of the aerial lift and never overload it.

Equipment operators should also complete a training course in fall arrest and falling hazards before operating a boom lift. The appropriate harness and lanyard are required for safe equipment use, and it would be best if the operator knew what they were doing regarding safety equipment.

Equipment Uses

Once the aerial lift has been properly inspected and is deemed safe for use, operators should follow these best practices when using it:

– Always use fall protection gear, such as a harness and lanyard. As a general rule, the lanyard should be short enough that if a fall should occur, the extended length of the lanyard should not exceed the distance between the floor and the basket plus six feet.

For example, a lanyard that is six feet long might open to ten feet upon fall impact, plus six feet for safety (so the operator doesn’t hit the floor), which would give us sixteen feet working height.

Here’s what the OSHA has to say about aerial lifts and PPE:

Under subpart L, employers must ensure that employees tie off at all times when working from an aerial lift [§1926.453(b)(2)(v)]. Employers must ensure that employees using personal fall arrest systems while working on aerial lifts at heights six feet or more above a lower level comply with §1926.502(d) of subpart M, specifically:

Personal fall arrest systems, when stopping a fall, shall:

… (iii) be rigged such that an employee can neither free fall more than 6 feet (1.8 m), nor contact any lower level. [§1926.502(d)(16)(iii)]

OSHA

That’s just the PPE involved in the equipment used. The equipment itself must only find a use for the appropriate job. In other words, crews mustn’t use an aerial boom lift for lifting heavy materials to height. The lift is not a crane. Its intent is to lift workers and their hand tools/equipment. The lift basket has a weight restriction that can seriously affect operation and tip-over hazard if not properly adhered to.

An operator must constantly be aware of their surroundings and constantly assess and re-assess the surroundings and the equipment capabilities during use.

Post-Use Inspections

Recognizing that equipment may become worn over time is essential but should not be abandoned to the pre-inspections alone. Often after use, while the equipment is warmed up, we can see things like hydraulic line sweating and other signs of fatigue that may not be visible until the equipment is warmed up.

Given that the equipment operator performed a pre-inspection, the visual memory of that inspection is fresh. They are the best person to look at the equipment quickly after use to ensure there are no signs of fatigue that require immediate concern.

Jobsite Conditions

Sometimes as managers, we are overly concerned with job completion, and that service coordinator might overlook something as seemingly trivial as the weather. However, any equipment used at height must maintain dry and clean conditions for workers. Workers mustn’t work in slick, wet conditions, especially while working at heights.

Further to atmospheric conditions, you must also have your team pay close attention to the ground conditions. Soft dirt after a rain can cause heavy equipment to sink in the dirt and even topple over easier as the earth beneath them gives way.

Inspection of the vicinity for holes and drop-offs is crucial when operating lift equipment, so this too is included in our aerial boom inspection checklist.

Digitizing Your Boom Lift Inspection Documents

In today’s business world, it’s more essential than ever to be able to work quickly and efficiently. That’s the reason why so many companies are turning to digital reporting apps to help them get the job done. Apps like 1st Reporting.

Pre-inspection equipment checklists are a perfect example of how a company can use a digital reporting app like 1st to improve efficiency. By digitizing these checklists, workers can complete them quickly and easily without spending time filling out paper forms.

1st Reporting doesn’t stop at mere equipment inspections, however. The app provides functionality for multiple industries and uses – from near-miss reporting to vehicle incident reports.

Some of the features you’re missing if you’re using paper forms include:

Mobile Reporting Including Offline Mode

The app works great on Android, iOS, Windows, and Mac machines. That way, no matter the smart device, your team can report. With the robust offline mode, they can even report while out of range of an internet connection. The app will upload its report when a link becomes available, so you never miss anything.

Customizability

Paper templates require design. The problem is if you change something, you need to re-print (making your order forms obsolete and wasting paper/ink). When you want to change something in 1st, you do it, and no printing of new forms is necessary. The changes are made for your whole team the instant you hit save.

Automation

Can a paper form send an email or notification to let you know that it was completed? If that were the case, our technology would look pretty different. However, we live in a world where magical paper is only make-believe. Technology, on the other hand, is a wonder to behold.

When one team completes an equipment inspection, you can receive an instant notification to let you know. Implement this with platforms like Microsoft Teams (1st is fully compatible), and you’ve got a powerful tool that can automate minor processes to increase efficiency.

Dynamic Structuring

Imagine a paper form that could change the following questions based on a previous answer? Well, with the customization and automation of our platform, you can dynamically structure workflows to vary based on the user inputs.

The app allows you to create dynamically controlled workflows to guide team members along a specific course of action. Tell me, can a piece of paper do that? We thought you’d come around. Give us a try and see just how deep the digital rabbit hole goes – and how you can use technology to make your job that much easier.

Featured Image: Fearl