Front-end loaders (aka wheel or bucket loaders) are one of the most used and least understood pieces of heavy-duty equipment. You can find front-end loaders in construction, agriculture, mining, and even public works use front-end loaders. As with any heavy equipment, a front-end loader must have a pre-use safety inspection performed by the machine operator to ensure safe daily operation.

The front-end loader inspection checklist is a document that operators use to inspect and audit the equipment for safe operation before use. The inspection checklist guides the operator through the machine’s major components to ensure that no step is missed during the inspection.

We’ve got just the thing for your team – a pre-built Front-End Loader Safety Inspection Checklist your operators can use before each shift to ensure optimal equipment operation and safety. Furthermore, a pre-use inspection helps to remind the operator about key safety concerns with operating heavy equipment, promoting overall safety-conscious operations.

In this guide, we’ll review what makes up the front-end loader inspection, what you’ll find on our generic downloadable checklist, and some best practices for monitoring and managing equipment and vehicle inspections. Furthermore, we will cover some best practices and tips for operators, so bookmark this page to help train and refresh your team. Let’s get started.

Included in the Front-End Loader Safety Inspection Checklist

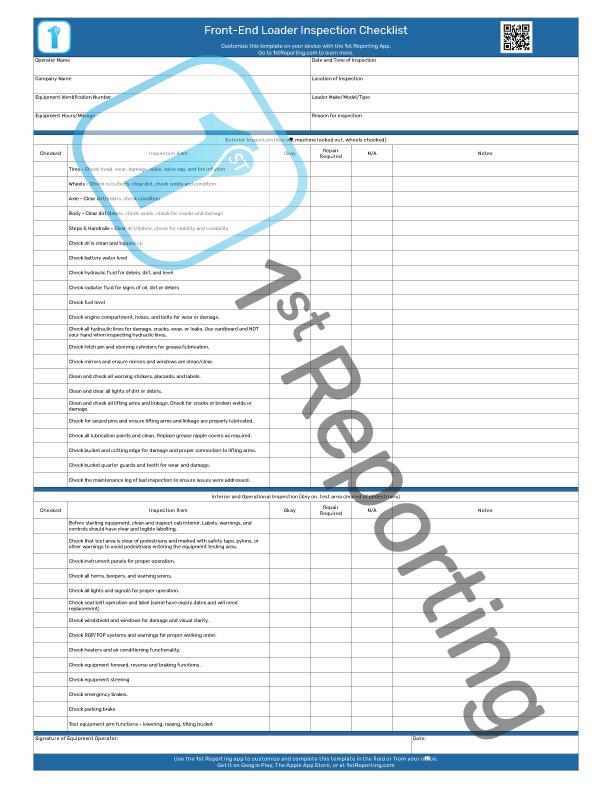

Our pre-use inspection checklist comprises three segments, notably the administrative segment, the ‘Key Off’ inspection items, and the ‘Key-On’ inspection items. Reading through the list, you’ll notice that the order takes a natural path through the specific equipment inspection items. Let’s review the inclusions so everyone starts on the same page.

Administrative Information

At the top of the Front-End Loader Inspection Checklist, you will find eight fields to include the name of the operator who is doing the inspection, the equipment identification information, the location, the company name, and the reason for the assessment are also included.

Exterior Inspection

The exterior inspection of the equipment should occur before starting the engine on the equipment. This portion of the inspection reviews and audits the condition of various external components such as tires, wheels, the body, and other exposed parts like the axle. Further inspection items include steps and handrails, fluid levels, and hoses inspection.

The inspection continues with safety items like mirrors and lights and includes cleaning of parts for visual access if the machine was not cleaned following the last use. Following this inspection, the operator will move to the interior cab for the remainder of the examination.

Interior and Operational Inspection

Assuming that all exterior components and inspection points are in good working order, the operator moves to the machine’s cab to review features like seat belts, dashboard switches, lights, instrumentation, and more. Finally, the inspector turns to the physical operation of the equipment and will test items like equipment steering, braking, ROP and FOP equipment, and arm raise, lower, and tilting functions.

Best Practices For Heavy Equipment Inspections

Inspection of heavy equipment is crucial to operator and pedestrian safety. Due to the importance of safety when working around heavy equipment, we’ve put together a few best practices to keep you and your team on the safe path of equipment use.

Standardize Inspection Item Order

We recommend approaching heavy equipment inspection like the front-end loader in three primary stages.

- Administrative – Check when the last inspection occurred and review it. Were any items unnoticed, or did items not receive the attention they deserved? An equipment inspection should always start with a review of the previous inspection’s findings.

- ‘Key-Off’ Inspection – After ascertaining that the last issues found were resolved, the operator should move on to the exterior ‘walk-around’ portion of the inspection. The operator should remember that they will need to test the equipment functions next, so they should preemptively cordon off the area or inform any stakeholders of your intention to test the equipment. Heavy machinery can easily crush a person, so you must exercise the utmost caution.

- ‘Key-On’ Inspection – Only after confirming the equipment is safe to start up, following the external visual inspection, do we anticipate starting up the engine and testing physical functions. Remember to ensure absolute safety when moving the equipment, even for a simple test.

Wear The Right PPE – Even For Loader Safety Inspections

One of the most common errors for heavy equipment operators is not complying with required safety during a simple machine inspection. It’s pretty well-documented that most accidents (88%, according to a study) happen close to home. This fact is likely due to the human trait of relaxing when comfortable and thus not paying as much attention as one would in unfamiliar situations.

Heavy equipment operators who become too comfortable with their machines tend to have accidents. Furthermore, it’s often the case that accidents happen with the most mundane of operations, like climbing the steel ladder to enter the cab.

Due to the increased likelihood of accidents when working around, with, or inspecting machinery that one is comfortable with, we recommend that full PPE is worn for the mechanical inspection. In this case, the PPE includes the following recommended items:

- High-visibility vest or shirt

- Gloves

- Steel-toed boots

- Hard hat

- Eye protection

- Hearing protection (during machine operation, if necessary)

3 Tips To Streamline Heavy Equipment Management

Heavy equipment management can challenge even the most experienced, driving frustration through the roof. However, it doesn’t have to be such a challenge; we’re not, after all, reinventing the wheel. So, just how can you streamline heavy equipment management? We’ve got a few ideas to help.

- Use a digital document platform for your mobile equipment inspections, job site conditions, and more. All you need to do is sign up for the 1st Reporting app and use our Front-End Loader Inspection Checklist from a mobile device.

- Standardize inspection procedures. By creating workflows where all stakeholders understand their roles, you can make a much more efficient set of processes and procedures. All you need to do is standardize inspection and incident management processes.

- Perform regular heavy equipment safety and operation audits. In many areas and municipalities, it’s mandated that heavy equipment operators inspect their equipment before use. It is a procedure that truck drivers have done for years, and for moveable earth-moving equipment like a front-end loader, it’s likely no exception.

- Regular inspections catch things like cracked welds, wear, or operational issues like broken controls, burnt-out lights, and other safety concerns.

31 Operational Tips For New Front-End Loader Operators

As mentioned above, the front-end loader is a complex piece of equipment that many equipment operators with minimal experience might consider as a simple piece of equipment. They couldn’t be more wrong. Front-end loaders, especially those that pivot mid-body, are tricky to master. Similarly, they require a certain amount of skill if you intend to operate the equipment at higher speeds (not recommended).

To help new heavy equipment operators, we’ve compiled 31 of the most essential tips for the safe operation of the front-end loader. Feel free to bookmark this page to help train your new operators and get everyone started safely on the same page.

Front-End Loader Safety Tips:

- If parking on a slope, have the machine face downhill with the bucket lowered to the ground, and the wheels chocked.

- Lower the bucket when leaving the equipment.

- Never let a person under the front-end loader.

- Never let people ride on equipment.

- Never swing or move the load with people in the area.

- Prevent backward tips by preventing jerky motion and using counterweights to stabilize the machine.

- Use a signal or communication system to ensure no one is injured in the work area.

- Clear the area before moving equipment.

- Articulating front-end loaders must be extra cautious.

- Never remove the PTO (Power Take-Off) guard – it can rip your arm off.

- Only use equipment with roll-over protection, including a seat belt.

- Never tow without a drawbar.

- Never leave the engine running and leave the equipment.

- Pre-plan the job for safety.

- Never smoke when refueling and ground out the fuel ejector against the vehicle’s body to avoid static shock igniting vapor.

Front-End Loader Operational Tips:

- Avoid steering jerk with a smooth turning motion by slowly starting and ending the turn.

- Lifting your tires off the ground doesn’t give you bigger scoops; it reduces your machine’s power forward, so maintaining a level scoop approach is essential.

- Avoid undercutting when possible.

- Avoid quick turns.

- When lifting, it changes the center of gravity, so be mindful of where the center of mass is.

- Keep the bucket low as much as possible.

- Watch for overhead clearance.

- Do not start a loader from anywhere except seated in the cab.

- Never exceed load limits.

- Tip over is easier with the bucket lifted, so go slow.

- Do not tow or pull anything from anywhere other than the drawbar.

- Use lower gears when going downhill.

- Avoid ditches, depressions, and steep slopes.

- Back up steep ramps.

- Know your machine – read your manual.

- Maintain equipment regularly.

Summary

In conclusion, the safety of front-end loader operators and the proper maintenance of equipment is paramount in ensuring smooth operations and preventing accidents. The front-end loader inspection checklist is a valuable tool to guide operators through the necessary steps for a comprehensive pre-use inspection.

We recommend enhancing equipment inspection documentation using the 1st Reporting app, a convenient digital document platform. This app lets operators access and use the pre-built Front-End Loader Safety Inspection Checklist directly from their mobile devices. Integrating digital solutions can streamline inspection processes, improve efficiency, and promote a safety-conscious work environment.

Remember, prioritizing safety during equipment inspections is crucial. Always wear the appropriate personal protective equipment (PPE), even during routine inspections, to minimize the risk of accidents and injuries. The PPE includes high-visibility vests or shirts, gloves, steel-toed boots, hard hats, eye protection, and hearing protection if necessary.

Additionally, implementing standardized inspection procedures and conducting regular safety and operation audits contribute to effective heavy equipment management. By establishing transparent workflows and ensuring all stakeholders understand their roles, you can optimize processes and maintain equipment optimally.

We hope this guide and the comprehensive list of 31 operational tips for new front-end loader operators provide valuable insights for safe and efficient equipment operation. Bookmark this page as a reference for training and refreshing your team.

Embrace the power of technology and prioritize safety by trying the 1st Reporting app for your equipment inspection documentation. Stay vigilant, follow best practices, and prioritize safety in all your operations.