Any experienced welder will tell you there’s more to welding inspection than just completing a weld visual inspection checklist. However, a good welding inspection template will assist even a veteran welder to make better welds. We’ve created a welding inspection template you can download and use for your business with that fact in mind.

Welding inspection includes quality control measures and analysis of completed welds to determine their quality and usefulness for the intended purpose. The assessment consists of visually inspecting the welds to determine penetration, fusion, and uniformity features. Documenting a welding inspection requires a robust welding inspection template.

We’ll dive into welding inspections and offer an actionable guide you can follow to determine the best use of a welding inspection checklist in your operations. Along with our downloadable template, it’s the perfect complement to a paper and pen inspection process. Stick around for some extra tips and tricks to inspections that will save you time and money, so don’t skip out and read through to the end; we’ve got a tip to save you a bundle!

Included In The Welding Inspection Checklist

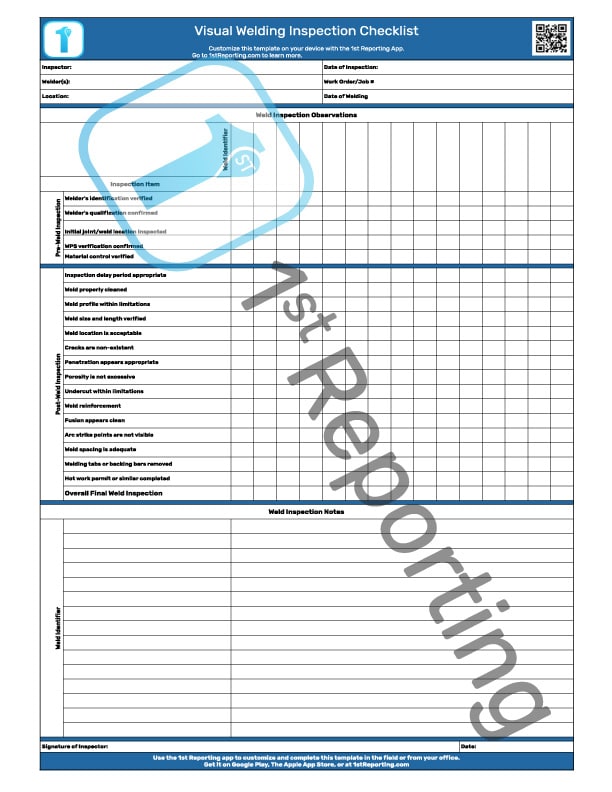

The Visual Welding Inspection Checklist contains four major sections to unify your weld inspection process into a streamlined protocol. Let’s take a quick look at each section to understand the best use.

Administrative

Every good inspection will require documentation. Retrieval of inspection notes at a later date is a feasible possibility, so you need to ensure that documentation is filed in a way that makes sense for retrieval and review efforts. With this in mind, we’ve included a handy area at the top of the Welding Inspection Template. Here you can record the preliminary information you’ll need to make sense of the document regarding storage and filing.

Depending on the function and nature of the welding job, your inspection might require more than a few welds inspected. For this reason, we’ve included the ability to report on up to 15 separate welds on the Welding Inspection Template.

Pre-Weld Inspection

Before welding a series of high-importance welds, it is often critical that a pre-welding inspection occurs. The review might include a visual inspection of the weld locations to ensure proper preparation. Similarly, some organizations might require verification of welder certifications or even verification of WPS (Welding Procedure Specification).

Post-Weld Inspection

After welding completion, all welds of significance must face evaluation. The post-weld section of the Welding Inspection Template documents the body and bulk of the inspection.

Weld Inspection Notes

Whether training new welders or merely noting remarks regarding weld observations, the weld inspection notes section is vital for identifying repair requirements or other observations. Similarly, the notes section includes a weld identifier column included with a notes column. Via utilization of the identifier column, each weld might retain its organized notes and observations without fear of misidentification.

Sign-Off

Ensuring the accuracy of inspections is of paramount importance. The sign-off section confirms the report’s accuracy via signature and date provided by the welding inspector of note.

Best Practices For Welding Inspections

The best practices for welding inspections ensure that the welds produced are of the highest quality. It can save time and money down the road, as welds that are not up to welding standards will need to be repaired or replaced.

By following our checklist and inspection protocol, you can ensure that all welds are adequately inspected and meet the highest standards to suit their intended purpose.

Let’s look at each stage of the weld inspection process and some best practices associated with each stage.

Pre-Welding Inspection

There are several key indicators to ensure a positive weld process. These indicators of best practices include verifying the welder’s skills and qualifications. They also include verifying that the WPS is up to date, checking for adequate preparation of weld locations, and ensuring that safety measures are in place. We’ll get back to the safety measure further down in the hot work section.

Pre-welding inspection includes:

- Proper material collection and preparation

- Welding matching inspection and preparation

- Site inspection completion to identify hazards

- WPS and job specifications identified and reviewed

- Safety protocol and equipment prepared and utilized

Mid-Welding Procedures

Mid-welding procedures include ensuring utilizing the correct welding process, monitoring the welding arc and temperature, and carefully inspecting for any signs of defects. Reactivity to the ongoing process is also essential.

A welding machine might require minor adjustments during the welding process. So pre-emptively reading through some checkpoints or the WPS before starting work yet after preparation is critical to utilize all the available information to optimize performance.

Post-Welding Inspection

Once welding is complete, it’s essential to examine each weld closely to ensure quality standards are present. It includes assessing any signs of distortion or defects, measuring the dimensions of each weld, analyzing the root opening and sidewall angle between adjacent plates or components, and looking out for contaminants or deficiencies in shielding gas coverage.

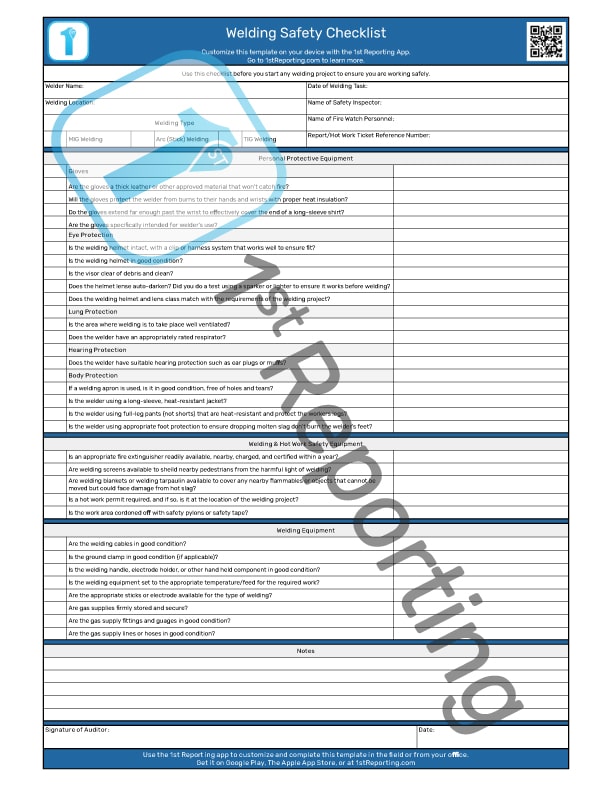

Hot Work Safety

Welding is a beneficial trade for most industries. However, it is not without its risks. Therefore, ensuring that one’s focus is on safety and the quality of outcome is of the utmost importance.

From acceptable preheat methods defined in a text to the welding procedure specification for the job, the act of welding consumables is always different from what one reads. The work is hot and dangerous. Without proper training on welding technique and safety, a welder might be in a seriously hazardous situation.

Welding, or hot work as many maintenance teams refer to it, is one of those tasks that require a specific process to maintain the utmost safety. Here is a list of safety checks to ensure your teams follow the highest standard>

- Inspect the work area for combustibles or flammable items, dust, or even gases.

- Ensure the work area is clean and no flammable are within a minimum of 15 feet. Remember that sparks can shoot pretty far, so maintaining a minimum safe distance to combustibles is critical.

- Ensure a spotter is available, with proper eye and breathing protection, to watch for sparks and potential fire.

- Ensure the team has appropriately rated fire extinguishers.

- Inspect welders and other equipment before use.

- Ensure welding screens or other area protection is available to avoid eye injury to passers-by.

- Notify anyone who is in the area before the welding. Ensure they understand the precautions as appropriate to the situation.

Now that we’ve addressed the welding progression, factors like adequate penetration, and other good practices, let’s move on to ways your business can improve welding inspections.

X Ways To Improve Welding Inspections

1. Check welder qualifications and certification

The first step to ensuring quality welds is to check the welder’s qualifications and certification. It will give you an idea of their skill level and what processes they are qualified to perform.

Higher qualified welders generally produce higher quality welds. They won’t have issues with their welding progression. The welder complies with higher standards, given that they have passed the appropriate test requirements. Higher quality welds make it easier to inspect and dramatically improve the inspection process.

2. Use up-to-date welding procedure specifications

Whether you work in a large manufacturing facility or a smaller shop, it’s essential to use up-to-date welding procedure specifications. It will ensure that your team uses the right processes and welding equipment for the job at hand.

3. Utilize inspection checklists

In order to consistently inspect welds and meet quality standards, you should utilize inspection checklists and templates. These documents can help you track careful assessment of critical factors like penetration, joint fit-up, and appearance of the weld.

Tracking welds via an inspection process is another great way to track team members’ abilities over time. By tracking incidents that reveal damaged or insufficient welds, we can assess the welding and inspection processes for improvement.

4. Perform regular inspections

Ensure you perform regular inspections throughout your workflow process. This procedure can help to identify any issues early on before they have a chance to impact quality or safety outcomes. By incorporating regular inspections into your routine practices, you can improve your welding inspection process and help to produce higher-quality welds every time.

5. Utilize a mobile form application for your inspections

The next time you need to find a welding inspection form from the past, how easy will it be to find it? Was it written legibly?

If you don’t have a solution for filing, retrieval, or legibility, you’re letting potential savings pass you. The time and effort to file, retrieve, and even decipher paper inspection forms is something you can’t get back.

What if you could easily track any visual weld inspection. Want to track welding machine calibration efficiently and effectively, even process ferrite measurement data? With the 1st Reporting app, you can do all that and more.

You can track any inspection, checklist, form, or otherwise with the robust and customizable mobile form solution from 1st Reporting. Due to the app’s customization features, you can track everything from checklists for appropriate pressure testing procedures to welder performance qualification reviews.

Using an app to track and monitor inspections and procedure qualification records means you have one source for your welding system needs. You can track required testing and provide your teams with training and references like welding symbols charts or automatic heat control settings tables. The sky is the limit with a secure and customizable solution like 1st Reporting.

Overall, there are many steps that businesses can take to improve their welding inspection process and also ensure consistent quality welds. Whether checking welder qualifications and certifications, using up-to-date procedures, or utilizing inspection checklists, these best practices can help you achieve the highest welding safety and reliability standards.