Whether your warehouse is bonded, consolidated, public, private, or another type, you need to ensure that you provide a safe work environment for your staff. Using a downloadable warehouse safety checklist, such as the one we have here for you is a wise choice in your battle with accident exposure.

What you need is a simple system for performing a warehouse safety audit, and a downloadable warehouse safety checklist is a great place to start.

The need for solutions in warehousing is more significant than ever. 2020 was a record year for warehousing due to the 44% growth in e-commerce in the US alone. This growth skyrocketed the need for warehousing, and many new jobs became available, which offset some of the job losses due to the pandemic. However, with a new workforce comes new problems.

The solution to the new found need for hiring staff in the warehousing industry is the maintenance of a well-suited warehouse safety inspection program. You need to manage and maintain safety for your existing staff and an influx of new potential talent.

We’ve created a comprehensive general warehouse safety audit checklist that you can download and use in your facility. Keep reading to find out more about the warehouse safety checklist, suggestions for use, and some clever tricks to help you expedite a smooth transition towards a more safety-oriented and efficient future.

Included In The Warehouse Safety Checklist

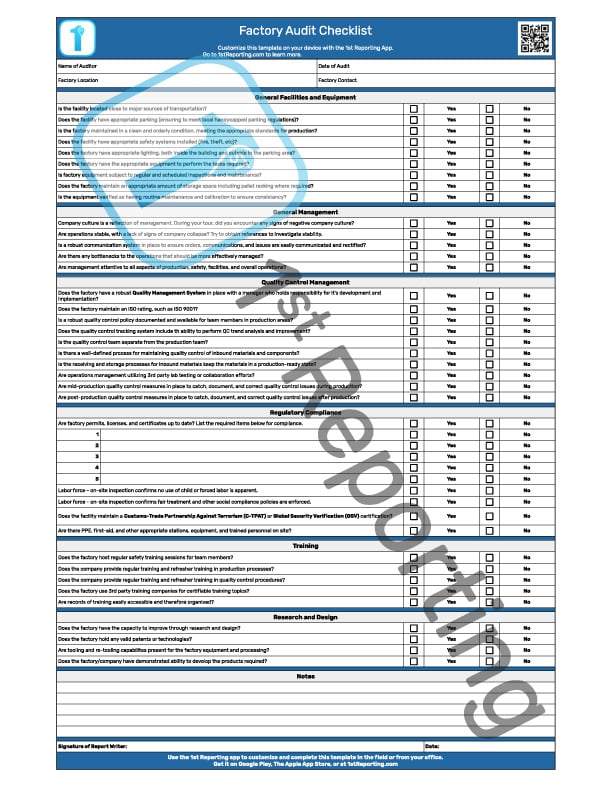

In the interest of keeping things simple and organized, we’ve compiled many of the most common safety questions that are asked in general warehousing safety audits. Together with a simple-to-follow 4-section layout, these questions make the warehouse safety checklist a great companion in your toolbox to prevent accidents and incidents in your facility. Here are the four primary sections as mentioned:

Primary Administrative Section

Straight forward and easy to understand, this section provides a place to formalize the data concerning who, where, and when the safety audit was performed.

Safety Audit Questions – Checklist Area

We’ve done our due diligence to try to find the questions that suit most warehousing situations. However, there are multiple warehousing types, and depending on the classification, this list might require a minor alteration.

For example, if your warehousing solutions are classified as licensable under the United States Warehouse Act (USWA), further inclusions might become necessary.

There are numerous other potential situations such as a climate-controlled facility, or border protection, or homeland security secure warehouses that would require entire other checklists to follow all potential regulations. However, in most common warehousing situations, the warehouse safety checklist ought to suffice. We recommend using a custom solution like the one we offer from 1st Reporting. This mobile app reporting solution can be used for any customized warehouse scenario, but we’ll talk a bit more about that later.

Each safety audit question on the warehouse safety checklist has a three-section response for your inspector to complete. The first is the check for an acceptable condition. The second is a check for an unacceptable or requires improvement condition. The third box allows a location identification of a particular item. It might come in handy for warehouses that carry multiple items such as fire exits or extinguishers.

The safety audit questions are further divided into segments to aid in the safety audit process for your chosen inspectors. The segments are:

- General Housekeeping

- Travel Areas

- Hazardous Materials

- Warehousing and General Safety

- Forklifts And Other Vehicles

- Tools And Equipment

- Warehouse Safety Items

Inspection Extras Section

If the warehouse safety audit checklist is just a few items short of being an excellent solution for your warehouse, we’ve added a few blank cell areas where you can have your inspector manually include those few extra items not already identified above.

Inspection Close-Out Section

At the bottom of the warehouse safety, audit template is a sign-off section where your inspector verifies by way of signature that the inspection is both complete and accurate.

How To Use The Warehouse Safety Checklist

For best results, we recommend that the warehouse safety audit checklist is completed weekly. At the minimum, the inspection ought to find completion with regularity similar to your mandated safety meetings.

According to the Oregon OSHA, most warehousing businesses must have a safety committee, and they must meet monthly. By this standard, the business should also have monthly warehouse safety audits and complete a warehouse safety checklist to include in the monthly safety meeting notes.

Train your inspectors to look for each item and focus on each segment at one time. With a focus on a specific segment of operations, inspectors have a better chance at catching those potentially dangerous situations that require attention and mitigation. Remember that a risk assessment does not need to happen only when there is a near miss. You can have your staff perform risk assessments as a function of their warehouse safety inspection or a part of a general facility inspection, or even a part of a general office safety audit.

Benefits Of Thorough Warehouse Safety Audits

There are several prominent and some not-so-obvious benefits to performing regular and thorough warehouse safety audits. Aside from limiting your liability exposure, there are several benefits to your staff, your company, and your clients, and society as a whole.

Here are the benefits, both obvious and obfuscated, to a thorough warehouse safety audit. We see these are having four segments of importance: Discovery, Verification, Prevention, and Management.

Discovery

- Discover and identify potential hazards

- Discover and identify new ways to improve operations

- Discover and identify new ways to improve facilities

- Discover and identify team performance

Verification

- Verify workplace safety conditions

- Verify workplace equipment conditions and operability

- Verify compliance with applicable local, regional, and federal laws and statutes

- Verify health and safety processes are functioning

- Verify prior identified hazards have been rectified

Prevention

- Prevent injuries and accidents

- Prevent costly breakdowns

- Prevent process stoppages

Management

- Manage company liability exposure

- Manage leadership team risk exposure

- Manage to create a better workplace culture through a safe work environment

Increasing Warehouse Safety Inspection Efficiency

The thought of including more inspections, more paperwork, and more processes often spells more headaches for management. However, what if you could abide by your legal reporting requirements, go one step further than what’s legally required to foster a culture of constant improvement, and automate the essential processes to increase process efficiency? Unfortunately, with modern technology, it’s no longer a dream. It’s a reality.

Technology is only one way we can improve reporting and safety auditing processes. Take the abundance of specialty warehouse types – bonded, public, private, agricultural, food-grade, refrigerated, and the list goes on. With such specialty operations, specialty checklists for your audits will be the only way your facility can improve process efficiency.

Enter EmAppetizer Inc and their 1st Reporting mobile application. You can get this cloud-based solution on Google Play or Apple App Store. It works on nearly every device and automates your customized reporting and auditing processes.

An entire library of standardized templates is at your disposal to begin your reporting processes, but each is fully customizable to endorse your warehouse’s individualized processes and requirements. In addition, you can alter just about anything; just get in touch with one of the 1st Reporting staff ready to help you customize your solution.

Why try it for free? Here’s a rundown of what it can do for your warehouse safety inspections. First, as mentioned, the templates are customizable. So, you can have the checklist customized to suit your operations.

Second, the application is mobile-friendly. So, you can have your staff complete the inspection on a smartphone, tablet, or laptop.

The app transforms your need for paper checklists into a digital solution. You’ll have no more mess of paperwork to sort, catalog, and file. Remove the entire paper filing process from your administration by using a digital solution. Upon completing an inspection, the report is uploaded instantly to the cloud, where you can access it from anywhere at any time.

Next, the instant and customizable notification features mean that you can set the system to notify you when your inspector completes the warehouse inspection.

The versatility of a digital solution is vast when you consider that it isn’t just capable of warehouse safety inspections alone. You can use the same application to digitally complete forklift, scissor-lift, or even aerial platform inspections. You can get your truckers to use the app for pre-trip vehicle inspections as well. If there’s a need for an inspection, audit, or other similar form or template, this application may just be the digital solution your company has been looking for. Test drive it today and see for yourself.