The Scaffold Inspection Checklist is vital to maintaining scaffold safety. Completing projects on time and without incident is vital to any project manager as you know. With the hazards of working at heights, temporary platforms like scaffolding require regular maintenance and even more frequent inspection. Your best tool to complete this is a comprehensive Scaffold Inspection Checklist, like the one we have here today.

A Scaffold Inspection Checklist is vital for completing the scaffold pre-inspection, post-assembly inspection, and daily-use inspections. These inspections are required for safety compliance on a job site using scaffolding.

We’ll take a look at the components of the checklist, so you understand how to best guide your team members on its use. As well, we’ll include some tips for effective and efficient management of the process after we discuss some of the best practices for use of the inspection checklist, so stick with us to the end of the article so you don’t miss out. Let’s jump right into what’s included on the checklist.

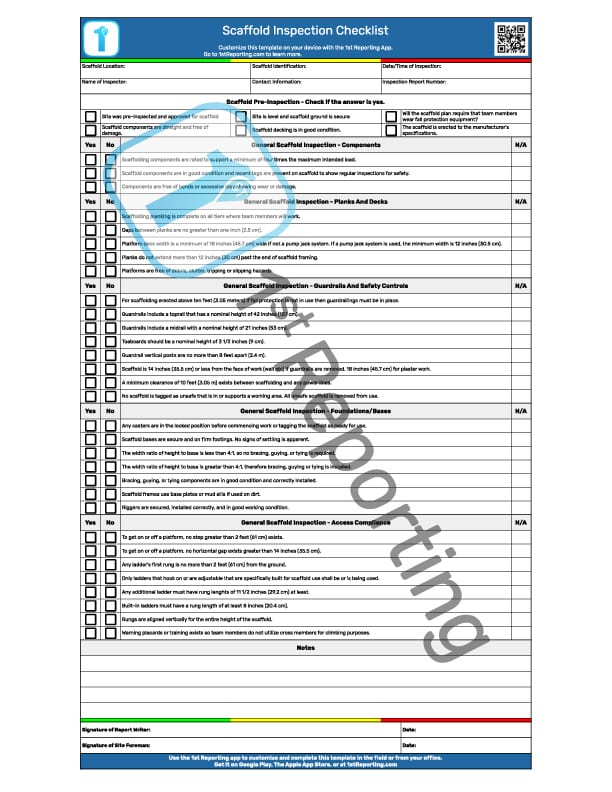

Included In The Scaffold Inspection Checklist

Scaffold inspection might get a bit tedious, depending on the scaffolding plan involved. That’s why we’ve conveniently broken down the topic of scaffold inspection into its primary six components.

- Scaffold Pre-Inspection

- General Scaffold Components

- Planks And Decks

- Guardrails And Safety Controls

- Scaffold Foundations And Bases

- Access Compliance

We’ll discuss each of these in brief detail below. Please note that this Scaffold Inspection Checklist mentions the use of scaffold inspection tagging. Please refer to our guide on Scaffold Tagging for further information about the tags and their green, yellow, and red color-coding system.

Before the Scaffold Pre-Inspection section, the checklist includes a brief administrative information area. In this area, the report writer will include the scaffold location, identifier, and date and time of the inspection. Similarly, there are also spaces to provide the inspector’s name, contact information, and the number assigned to the inspection report.

Scaffold Pre-Inspection

Before scaffolding is erected, there are two primary inspections that you must complete. The first is a Site Condition Audit and the second is a Scaffold Equipment Pre-Inspection.

The Site Condition Audit should focus on the ground where the scaffold will be set up and other environmental factors that will affect working conditions.

The Scaffold Equipment Pre-Inspection typically occurs when the scaffolding is delivered to the site. Any pieces that are bent, damaged, misshapen, or otherwise unacceptable are discarded and tagged out as unsafe.

The Scaffold Pre-Inspection segment of the Scaffold Inspection Checklist covers some of the basic topics of equipment condition, ground condition, and other general topics such as whether the plan will require team members to use personal protective equipment. Don’t forget to check with your local authorities for local worksite safety requirements to ensure your plan is up to code.

General Scaffold Components

The General Scaffold Components section of the Scaffold Inspection Checklist includes load ratings and a focus on conditions for singular components such as joints, cross braces, or other components.

Planks And Decks

Planks and decking are vital to creating safe work platforms where team members can safely work. The General Scaffold Inspection – Planks and Decks section of the Scaffold Inspection Checklist includes topics relating to the decking used in scaffold installations.

The spacing requirements are used based on OSHA standards at the time of writing. However, we strongly advise that you check with local authorities for the particular requirements in your region and merely use our checklist as a general guideline in case your area has slightly different rules.

Guardrails And Safety Controls

Some scaffold systems are set up to include guardrails so staff may safely work without the impedance of full-body harnesses and other fall protection equipment. In these cases, there are specific guidelines and requirements for guardrails used on scaffolding systems. We’ve done our best to include the latest guidelines but again, it may be slightly different in your area depending on what country or region you operate your business in, so be sure to check with your local regulations.

Scaffold Foundations And Bases

Foundations and bases are key to a safe and secure scaffolding installation. Due to their importance, an entire segment of the Scaffold Inspection Checklist is dedicated to topics relating to the bases and foundations of scaffolding systems.

Access Compliance

The means by which team members enter, ascend, and descend within the scaffolding must meet certain safety requirements for it to pass inspection. We’ve included the general basic concepts for entry and exit points as well as the ascending and descending ladder rules for scaffolding installation.

Following the access compliance section of the Scaffolding Inspection Checklist, resides a notes section where your inspector can include their site-specific recommendations or observations. Finally, there is a sign-off area where you’ll find a place for signature and date for both the report writer and the site foreman.

How To Use The Scaffold Inspection Checklist

When performing scaffold inspections there are three vital inspection time requirements.

- Pre-Inspection

- Post-Assembly Inspection

- Daily Use Inspection

We recommend that you download our template prior to the first pre-inspection. In fact, we also have a Site Condition Report Template you can download from our incident report template library to get you started.

Once you’ve downloaded the Scaffold Inspection Checklist, you should consider the pre-inspection of both site and equipment. After completing both of these preliminary inspections (don’t forget to assign an inspector that has training in scaffold installation and is of a sound and competent nature).

Disperse copies of the Scaffold Inspection Checklist to suit your worksite or site’s needs. Remember that there should be a pre-inspection, a post-assembly inspection, and also daily inspections to ensure safety for your team members and compliance with the local regulations you will confirm for your area before starting work on your project.

Remember to make a lot of copies of the Scaffold Inspection Checklist. The reason is that you’ll need a copy for each day of work. If you don’t want to print a huge pile (maybe your project is going to last more than a few days) then you may want to consider a mobile form automation solution like 1st Reporting instead of the printable template we’ve provided.

Let’s jump into some of the best practices to help you with managing scaffold inspections and the inspection process. After all, inspections have a bad reputation for slowing down worksites and costing companies money. Let’s see if we can lend some advice to help this situation.

Best Practices For Managing Scaffold Inspections

Project management is a tough job. It’s tough because you have to remember multiple things in multiple disciplines and time everything accordingly in the face of the usual logistical nightmares life will throw at any project manager. For this and other reasons, we’ve put together this helpful and actionable list of tips to help you manage your scaffold and other workplace inspections.

Although most of the tips can be applied to many types of industries and situations, some are only for scaffolding installations, so ensure you don’t skip any of these tips.

- Train Staff Well

- Re-Train Staff Regularly

- Maintain A Minimum Of One Inspector With One Backup

- Schedule Inspections Prior To Site Operating Hours

- Repair Scaffold Immediately

- Keep Extra Common Components Like Planks Or Decks

- Use Waterproof Scaffold Tags

- Keep An Inspection Log Book Or Accessible Records

- Use A Mobile Reporting Application

Train Staff Well

Scaffolding is a common sight on commercial and residential construction sites. The scaffold platform, which typically rests atop the building’s existing structure or other forms of support, provides an elevated surface for workers to assemble and disassemble materials. It also creates an area where they can work at heights safely by providing guardrails and safety equipment such as personal fall protection systems to protect them from falls.

Working at height is not without its dangers, however; there are many potential hazards associated with working at heights such as falling objects, slips, and trips, electrocution from faulty equipment or electrical wiring near the site, structural collapse due to poor design or damage in high winds, etc. To help manage these risks workers must be trained in risks associated with scaffold use:

- How to safely erect, work on and dismantle a scaffold

- The use of personal fall protection systems

- How to identify and report faulty equipment or practices

- Any other specific risks associated with the type of scaffold being used

Re-Train Staff Regularly

Regular refresher training is also essential, as workers can forget safety procedures if they’re not regularly reminded of their importance.

Maintain A Minimum Of One Inspector With One Backup

A competent person must always be in charge of inspecting the scaffold and its components for any defects that could affect the safety of workers. This person should have a good understanding of how to safely erect, work on and dismantle a scaffold, as well as how to identify and report faulty equipment or practices.

It’s also a good idea to have a backup inspector in case the primary inspector is unavailable for any reason.

Both inspectors should have adequate training and certification as required.

Schedule Inspections Prior To Site Operating Hours

Inspections are required to ensure the safety and proper use of a site. They provide a final check for any issues that need to be addressed before the equipment is in operation.

In order to avoid any delays caused by inspections, it’s an excellent idea to schedule your inspections prior to operating hours. Time this right and your worksite could hum along like a well-oiled machine.

Repair Scaffold Immediately

One of the worst things you can do when managing a project is to put off what needs completion. Damaged scaffolding can cause serious safety concerns and an injury or worse can shut down a job site. To avoid such catastrophe, don’t postpone any scaffold repairs or component replacement requirements. Rushing a job for the sake of a deadline is never worth risking the lives of those that make your project a reality.

Keep Extra Common Components Like Planks Or Decks

It’s not uncommon for workers to need to replace scaffold components. For example, if a plank breaks or is removed by accident, it needs to be replaced. Likewise, if a worker notices that there are missing bolts or screws on the scaffolding platform, they should replace them before someone gets hurt. The best way to ensure that you have enough spare parts at your site is by keeping extra common components like planks and decks around in case they’re needed when working on any of your projects. This process can help avoid costly delays due to waiting for parts.

Use Waterproof Scaffold Tags

Waterproof scaffold tags can be an extremely valuable tool for scaffold safety inspections at outdoor job sites. Having a designated area on the tag for the inspector’s signature can help ensure that all workers on the scaffold have been properly inspected. But that signature needs to retain legibility.

In addition, the use of waterproof scaffold tags can help keep track of any damages or defects that are found during inspections. This information can then be used to create a report of any issues that need to be addressed.

Having this kind of documentation can be extremely helpful when trying to keep your job site safe and compliant with all safety regulations. Having rain or spilled water wash away your scaffold tag information is not a situation you want to encounter, so try using waterproof tags instead.

Keep An Inspection Log Book Or Accessible Records

In order to maintain a good record of your scaffold safety inspections, it is essential to keep an inspection logbook. The inspection logbook should include information about the date, the inspectors who were there, and any other components that need to be replaced.

It should also include any defects or issues that need to be addressed. This will aid you in maintaining a compliance record with all safety regulations and will make it easier for you or someone else from the company to access the records if needed.

The records should be kept on-site for easy retrieval.

Use A Mobile Reporting Application

There are several benefits of using a mobile reporting application instead of using paper checklists. First, a mobile reporting application can help you keep track of your inspections. You can easily enter the date, time, and inspector’s name in the app. Then you can retrieve based on specific parameters, something impossible with a physical filing system and paper files.

Second, a mobile reporting application can help you keep track of any damages or defects that are found during inspections. This information can then be used to create a report of any issues that need to be addressed. The reports can use intelligent logarithms to analyze data and present that analysis in the form of a generated report. Again, something that requires a person to sift through paperwork for hours or even days with a paper filing system – a feat easily achievable in seconds with a smart application.

Third, a mobile reporting application can help your inspectors by utilizing customization to create a site-specific, scaffold installation-specific audit form. Sure, you could have someone draft up and design a paper version, but if you could do this digitally, wouldn’t it be so much faster using a template?

There are multiple other benefits of using a system like the 1st Reporting app. Aside from allowing customized notifications (so you can have your site foreman notified the moment the scaffold inspection is submitted) the sheer benefit of near-instant form retrieval is a benefit that no filing cabinet could ever bestow.