In an ever-evolving world, safety in the workplace has become more than just an idea; it’s become a day-to-day operating reality. Measuring indicators and reacting to calls for improvement is essential in today’s world if a business succeeds. And so, the safety leading indicator facilitates this purpose.

The Safety Leading Indicator tracking form enables organizations to record and track potential leading safety concerns. The vital information recorded plays a crucial role in incident prevention in the workplace, contributing to leading and lagging indicator analysis.

Safety Leading Indicators: Proactive Measures for Workplace Safety

Tracking the metrics an organized safety program provides allows organizations like yours to make positive determinations for a safer working environment. Any safety-conscious company aims to use safety-leading indicator data to improve workplace safety and implement procedures. And so, without further ado, we bring you the form your business needs for tracking leading safety concerns, near misses, and more.

The Safety Leading Indicator Form

Included In The Safety Leading Indicator Form

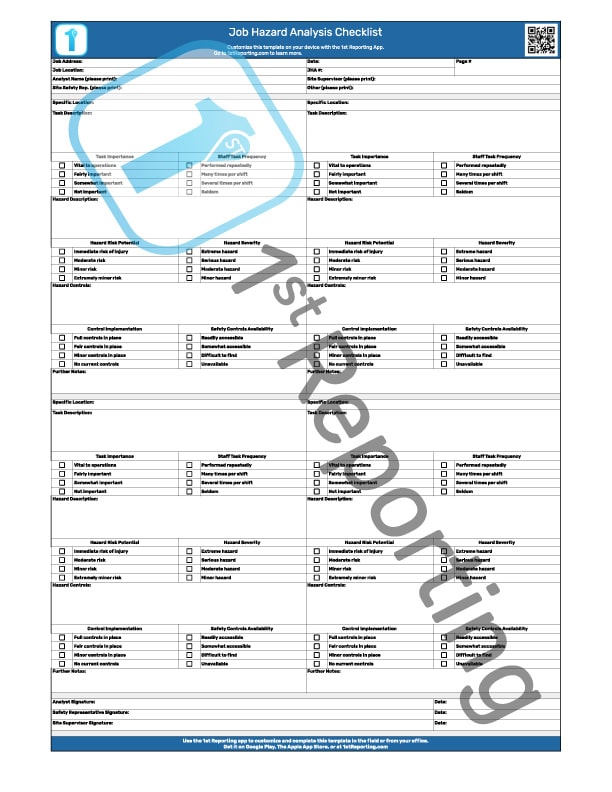

The safety leading indicator form includes four primary sections for your staff to complete. The first section details the administrative data required. It consists of the report writer’s information, date, time, location, and the general type of safety incident reported.

Following the administrative section is another checkbox where the reporter may note the type of safety concern. Again, several of the most common concerns are listed, and a place is provided for the reporter to note if other items not included in the common concerns area are required.

The third and fourth sections of the safety leading indicator form allow the reporter to describe the potential incident or threat in detail. The form also includes an area for the reporter to include recommended preventive actions.

How To Track Leading Safety Indicators

The idea behind the safety leading indicator form is simple: record potential hazards or incidents to track and prevent them. Here are a few easy-to-follow steps to implement this form in your company’s safety program.

- Download and print the Safety Leading Indicator Form.

- Provide copies of the form to your company safety representative and other appropriate personnel.

- Train your staff to note potential issues that could cause a hazard or incident.

- Receive completed forms and apply the necessary preventive measures.

- File your safety-leading indicator form for future analysis.

Safety Lagging Indicators: Evaluating Past Performance

The title defines it well, but for those who could use a refresher, lagging safety indicators are metrics we use to review previous safety incidents and their subsequent outcomes. What they are effective at is revealing ways that your organization can improve.

Common Safety Lagging Indicators – Examples

- Total workplace injuries over time – A measure of the total injuries or illnesses within a given period of time.

- Lost-Time Injury Rate (LTIR) measures the number of lost-time accidents and injuries per million hours worked.

- Compensation Claims Count (CCC) measures the number of lost-time incidents that resulted in claims for a period of time.

- Number of Safety Incidents—This is, as expected, a count of the number of safety incidents over a period of time.

Limitations of Lagging Indicators

Although it’s wise to track, analyze, and review lagging indicators so your operation might improve safety, this methodology has limitations, the least of which should catch your attention immediately: Lagging indicators only track incidents that occurred—they do not track potential incidents.

Adding Value To Your Safety Program – Implementing a Reporting Methodology for Safety Indicators

Every company with a proactive approach to safety will benefit from adding safety-leading indicators. There are multiple benefits to using indicators to track your company’s workplace health and safety risk.

- Prevent injuries and illnesses in the workplace

- Prevent costly downtime

- Reduce potential related expenses

- Improve worker confidence and productivity

- Improve company processes, procedures, facilities, and even equipment.

Any company’s primary concern is preventing harm to people, be it staff or the general public. When tracking incidents and safety concerns, utilizing leading indicators benefits the company by isolating hazards before a costly or dangerous event.

Improving worker confidence by supporting proactive measures to make a safer workplace benefits employers by producing more efficient staff. Staff who feel comfortable and safe will be more confident by nature and thus more productive.

While incidents may provide great insight into our lagging indicators, safety-leading indicators allow us to act preemptively. A company’s savings from preventing incidents alone show that a robust health and safety program is useful and necessary. It might be hard to see the cost savings without first seeing the costs of an incident. Let’s take a look at some of those costs.

US Work Injury Costs (2018)

- Nationwide $170.8 Billion

- Per Worker $1,100

- And Per Death, $1,190,000

- Per Medically Consulted Injury $41,000

(source)

These numbers show us that the cost across the United States in 2018 for all work injuries was nearly 171 billion dollars. The cost per worker includes the goods/services each worker provided to offset the cost. It is not average. The per-death cost includes all lost wages, admin fees, and other expenses. The courts likely determined the cost to the actual businesses in many of these cases, and they would not have been lenient.

Best Practices for Using Safety Leading and Lagging Indicators

Safety leading and lagging indicators are crucial for evaluating and improving workplace safety. Furthermore, we can combine proactive measures and tracking with retrospective analysis to reveal patterns and trends in our operations. Let’s take a minute to look at some of these best practices for using safety-leading and lagging indicators.

Balance Leading and Lagging Indicators for Comprehensive Safety Management

- Utilize leading and lagging indicators to gain a holistic view of safety performance.

- Use leading indicators to identify potential risks and take preventative measures.

- Use lagging indicators to evaluate the effectiveness of safety initiatives and analyze incident trends.

Encourage Employee Participation in Safety Reporting

- Foster a culture of open communication where employees feel comfortable reporting safety concerns and near misses.

- Implement reporting mechanisms that are accessible and easy to use, such as online forms or mobile apps.

- Acknowledge and reward employees for their contributions to safety reporting and improvement.

Continuously Monitor and Improve Safety Performance

- Regularly review and analyze safety data to identify patterns and areas for improvement.

- Conduct periodic safety audits and hazard assessments to identify risks proactively.

- Use the insights from safety indicators to inform and update safety policies, procedures, and training programs.

Set Realistic and Achievable Safety Goals

- Establish clear and measurable safety goals based on leading and lagging indicators.

- Communicate safety goals to all employees and explain how they contribute to workplace safety.

- Monitor progress towards safety goals and adjust strategies to achieve desired outcomes.

Integrate Safety Indicators into Organizational Decision-Making

- Ensure that safety performance data is accessible to key decision-makers within the organization.

- Safety indicators are key when making operations, staffing, and resource allocation decisions.

- Prioritize safety improvements based on data-driven insights from safety indicators.

Safety Leading Indicator Tracking Tips

We recommend a few things to help you track and improve your health and safety program for optimal results. First and foremost, there is an essential fact that many companies fail to keep in mind:

Health and safety start at the top but shouldn’t end at the bottom.

Top management must be the first to buy in, but similarly, every team member must be made aware that taking part benefits everyone. Often, staff may feel they should not report safety concerns for fear of retribution. Managers must train staff to embrace a safety culture that is supportive and understanding. Worker participation is the key to preventive action.

Track multiple indicators.

The purpose of safety-leading indicators is more than finding potential issues and resolving them. By tracking multiple safety indicators, patterns may begin to emerge over time that can give insight into why certain occurrences happen frequently. Through data analysis, companies may find that they can counter specific patterns with predictive patterned behaviors and processes.

App Reporting Solution – An Alternative To Printed Forms For Indicator Documentation and Analysis

Any company with an ambitious staff may find that the daunting task is not correcting safety concerns; it’s organizing all the paperwork. The form we’ve provided is an excellent tool if your business only has one or two forms to complete per year. However, a digital solution is more appropriate for most businesses that want to stop printing. Let me tell you about the 1st Reporting app (available on Google Play and the Apple App Store).

Benefits Of The 1ST Reporting Mobile App – A Solution For All Incident and Report Management

Using a platform instead of printed reports and forms is the future of health and safety. We can preserve our environment each time we say no to printing unnecessarily. And that’s just the tip of the iceberg.

- Upload multimedia files – Add photos, video, or audio to your report quickly and efficiently.

- Easy-to-use interface—The 1st Incident Reporting App interface is clean and intuitive. Its straightforward functionality makes reporting fast and efficient.

- Customizable reports and forms – Adding another field or customization is a blessing when you want a specific form set up for your business.

- Automated filing and retrieval—No filing cabinet is required. The manager’s dashboard allows reports and forms to be easily retrieved and managed.

- Instant notifications – Here’s something your filing cabinet can’t do yet – send you a customized notification, something easily set up with 1st.