The maintenance work order is dead. Long live the maintenance work order! This article will explore what it means to have a maintenance work order system that works for you and your team. We’ll focus on how to get started and some of the things you need to consider while designing a process that will make your work easier and more efficient.

Maintenance work orders are essential for any organization that relies on physical assets. Whether it’s a factory, an office building, or a rental home, maintenance work orders provide a way to track repairs and improvements that need completion.

A sound maintenance work order system will save you time and money by preventing minor problems from turning into big ones. It will also help you keep track of the work done on your property to budget for future maintenance needs.

Getting started with a maintenance work order system is easy. If you don’t have one in place, now is the perfect time to start. The first step is to choose a work order template that you can use to track repair and maintenance requests.

Many different work order templates are available online, but not all of them are created equal. When choosing a template, look for one that is easy to use and understand. It should also be able to be customized to fit the needs of your business.

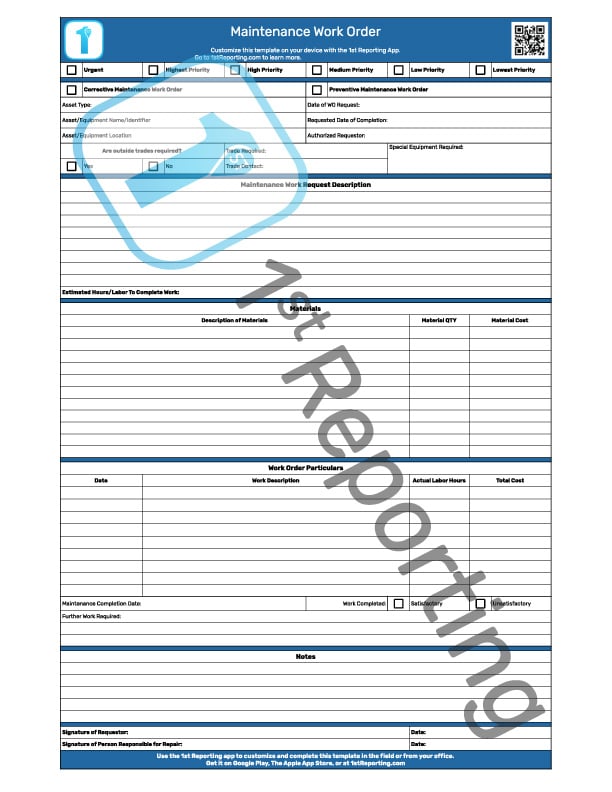

Today, the Maintenance Work Order template we provide is a dual-purpose form. The template design matches both preventive maintenance work and corrective maintenance needs. Let’s look at what’s on in this dual-purpose maintenance work order.

Included In The Maintenance Work Order Template

Eight sections create the bulk of the maintenance work order template. These sections are as follows:

- Maintenance Priority

- Administrative Data

- Work Request Description

- Materials Required

- Actual Work Particulars

- Work Completion Summary

- Notes

- Sign-Off

For clarification purposes, we’ve detailed each segment briefly below. Remember, you can always have your team read this article for more particular document training as a part of your occupational health and safety program.

Maintenance Priority

One of the essential aspects of any work order is noting the priority for the work required. This information will help you and your team prioritize the work and ensure that the essential tasks are completed first. It is also necessary for budgeting and scheduling future work.

Administrative Data

Having complete administrative information is critical when it comes to maintenance work orders. This information can include the name of the person submitting the request, the property or asset requiring maintenance, and contact information for the person in charge of completing the work.

This information readily available makes it easier for everyone to stay on the same page and ensures that those performing the work do so on time.

Work Request Description

The work request description is where you will detail what needs to be done. It can include anything from a general description of the work to specific instructions on how to complete the task.

It is essential to be as clear and concise as possible when writing the work request description. It will help to prevent any confusion or misunderstandings down the line.

Materials Required

There may be specific materials required to complete the work in some cases. Be sure your team lists them out in this template section if this is the case. It will help ensure that they have everything they need before starting the job.

Actual Work Particulars

This section is where your team will detail what they did to complete the task. Particulars can include information like keeping track of the work ticket hours worked, the work completed, and any materials used.

Work Completion Summary

The work completion includes the maintenance completion date and whether or not someone satisfactorily completed the work. Similarly, sometimes when repairs occur, people may find that further work is required beyond the scope of the work order. In this case, the additional work required section provides a space for including such notes.

Notes

Your work order writer may not have enough space to include all particulars or observations. That is, depending on the nature of the work involved. Therefore, we’ve included a notes section before the sign-off to fulfill any overflow information.

Sign-Off

No work order is complete without a sign-off section. Our downloadable maintenance work order template includes two places to sign. The first is a location for the work order requestor to sign and date upon approval of the work completed. The second signature and date location are for the person responsible for completing the work requested.

Best Practices For Using The Maintenance Work Order

Following best practices for creating and completing maintenance work orders can benefit your team. Some of the key benefits include:

Efficient Communication – By following a set format for your maintenance work orders, you can help ensure that everyone involved in the process is on the same page. It can help prevent any confusion or miscommunication that could delay the completion of the work.

Improved Tracking – Having a standard format for your work orders can also help track and keep records of the work completed. It can be helpful for budgeting and scheduling future work.

Better Documentation – It may be essential to document the work completed in some cases. For example, if you are a property manager and need to provide proof of work completed to a tenant or an insurance agent. Having a maintenance work order template can help ensure that you have the documentation you need.

Steps To Completing And Managing Maintenance Work Orders

The following eight steps are those we recommend for you to train your team. Following these steps uniformly across your company will aid in streamlining the process as well as allowing all those involved to understand the requirements for maintenance work order completion.

1. Prioritize work orders according to maintenance priority. It might seem obvious, but you’d be surprised by how many people struggle with prioritization.

2. Make sure all necessary information is on the work order.

3. Write a clear and concise work request description. There is nothing worse than messing up a maintenance job due to miscommunication.

4. List any specific materials required for the task. It effectively streamlines a parts ordering process (if applicable), but it also helps provide any potential technicians with an idea of the parts involved.

5. Detail the actual work particulars for post-maintenance cost evaluation.

6. Include a summary of the completed work. It is vital for recording purposes to know the details of work completed, especially if one needs to reference it later.

7. Use the notes section for any additional information. It may be an obvious, even a moot point, but we have witnessed many situations where maintenance technicians did not note information due to a claim that they ran out of space on their report. Naturally, we want to avoid this excuse for inconsistency and thus have provided a notes section for further information.

8. Have both the requestor and the person responsible for completing the work sign and date the work order. Ensuring you’ve trained your team on the importance of quality pride, a signature will guarantee (at least on a psychological level) that those providing the maintenance will do their best.

5 Tips For Managing Maintenance Work Orders Effectively

- Create a system for submitting work orders. Utilizing a standard for reporting practices and work order submission is essential for team members to catch errors. If work orders are always different, it will be easy for mistakes to sneak through the cracks.

- Keep track of open and closed work orders. Passively tracking closed work orders is one way that companies are increasing their asset breakdown prevention potential. For example, monitoring parts’ life expectancy will allow a pre-emptive maintenance repair before part failure. A team member might only catch this situation when tracking a potentially closed work order that notes the original installation of the part in question.

- Assign someone to be in charge of managing work orders. Increase efficiency and accountability by assigning the work order management to a single individual.

- Follow up with requestors after the work completion. Following up with requestors does two things. First, it shows due diligence to correct an issue. This due diligence will foster better company morale, guiding team members that when something requires repair, it gets fixed. Secondly, following up allows you to track various aspects of the exchange, such as whether or not the maintenance was completed satisfactorily.

- Use a software system to help manage work orders. Many companies use paper-based work orders but find several drawbacks to the scenario.

First, paperwork is easy to get dirty or damaged. When work requires physical exertion, technicians in the field usually lower the bar for their paperwork based on their physical efforts.

Second, paperwork is easy to lose. A piece of paper in a service truck is quickly lost as it might blow out the door or even slide under a seat or fall on the floor unnoticed.

With our maintenance work order template, you can easily create and track work orders. It will help ensure that those involved complete all necessary tasks quickly and efficiently.

However, many a company or organizations utilize multiple work order types or multiple types of forms, checklists, or even inspections templates. A paper document may not be the correct answer for your reporting and documentation needs.

A Digital Work Order System

Transforming from paper and pen to a digital form might seem like a crazy idea. But if you think saving paper, ink, or even printer rental or purchase cost is crazy, then stick with the downloadable template.

If you’re a little more adventurous and want to learn how we can help you drastically reduce your dependence on paper checklists, forms, and templates, then read on.

Going digital with your reporting and documentation needs is the next logical step in your maintenance operations process’ evolution.

Have you lost your clipboard? Are you tired of printing out forms?

1st Reporting is the perfect solution for you! Our app is digital, cloud-based, and works offline – so you never have to worry about losing vital information again. Plus, it’s excellent for inspections, audits, checklists, and forms.

Stop wasting time and start using 1st Reporting today! With our app, you’ll be able to complete your tasks quickly and easily – without ever worrying about losing anything essential.