Looking for a better ladder inspection checklist? You’re in the right place. As much as we would like to use lift equipment instead of ladders, ladders have been and will continue to be a part of facilities and structures for the foreseeable future. Therefore, a robust ladder inspection checklist and inspection process are vital for safe operations.

Organizations can use our ladder inspection checklist as a comprehensive tool for annual and regular ladder inspections and analysis of the ladder’s preferred location for use. It is the only tool you need for tracking ladder condition, maintenance, repair, and service.

In this guide to accompany the downloadable template, we’ll talk about a few best practices, not when it comes to using a ladder, but regarding ladder management. We will also discuss some tips and tricks to manage your company’s risks and liability in a more manageable and efficient way.

Included In The Ladder Inspection Checklist

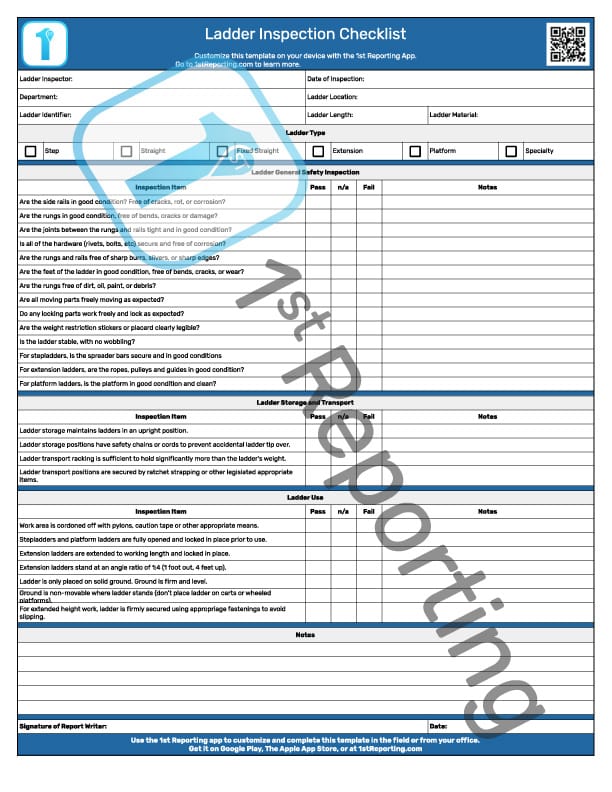

Our comprehensive ladder inspection checklist is comprised of 5 sections. These sections are:

- Administrative

- Ladder General Safety Inspection

- Ladder Storage and Transport

- Ladder Use

- Notes & Sign-Off

Let’s take a quick look at each of these sections and their intent. You can use this guide to train your team to perform ladder inspections on your behalf.

Administrative

Filing documents and tracking them so that you can reference them later is critical for any inspection process. The administrative section of the template allows you to document the person doing the inspection, their department, a ladder identifier, the date of assessment, and further information regarding the ladder type, length, and construction material.

Documenting the information about who, what, and where the inspection took place is essential for referencing documentation at a later date. It also helps prove that the assessment was completed and by whom.

Ladder General Safety Inspection

The Ladder General Safety Inspection section of our checklist pertains to the general construction and condition of the ladder. This section is utilized for regular and annual ladder inspections; however, for those who use ladders every day in your trade, it is best to inspect the ladder before use at the beginning of each shift.

Ladder Storage and Transport

Ladder storage and transport are often overlooked when it comes to ladder inspections. Most inspection checklists are concerned with the general condition of the ladder, which is fine, but what about where and how the ladder is stored or transported? The transport of a ladder can significantly affect the condition and, thus, the safety of use.

Companies with service crews that use ladders daily should take special note of this section of the checklist. This section will give you insight into best practices for ladder storage and transport.

Ladder Use

We’ve looked at the ladder; we’ve looked at how we store and transport it. Finally, we analyze the conditions and method of use. This section examines items like ground level and conditions and the extension ladder setup ratio (1 foot out, 4 feet up, or 1:4 if you prefer).

Notes & Sign-Off

The final section of the Ladder Inspection Checklist is an area where you can document any further notes or concerns discovered during the inspection. Similarly, a section to include a signature of report authenticity and date exists.

How To Use The Complete Ladder Inspection Checklist

The Ladder Inspection Checklist is simple to use: Download, print, and use it. Then, file it away in a safe place for future reference.

If one of your team members has a concern about a ladder, we recommend removing it from service immediately and replacing or repairing it when deemed appropriate. Always have a professional repair ladder. In many cases, especially with fiberglass, when the structure of the ladder deteriorates, it is usually beyond repair. For this reason, a trained professional must perform the final assessment, determining the feasibility of ladder repair versus replacement.

We recommend that you use our ladder inspection checklist in the following scenarios:

- Annual ladder inspections

- Ladder daily-use inspections

- Ladder storage area inspections

- Ladder site use inspections

- Ladder transportation assessments

- Ladder storage assessments

6 Actionable Tips For Managing Ladder Use, Maintenance, And Repair

Keep Ladders In Good Condition

This first tip may seem like a no-brainer, but you’d be surprised how many companies don’t know to watch for these vital conditional concerns:

- No cracks or damage to the rungs or rails

- The safety placard noting capacity is legible

- All hardware is firmly secured

Other points of interest are also easily forgotten, which is why using a checklist like our Ladder Inspection Checklist is vital for keeping ladders in good condition.

Properly Store And Transport Ladders

Proper storage and transport of ladders are often neglected until an accident occurs. Improperly storing ladders can introduce weaknesses, causing damage, cracking, and other issues that could compromise their integrity.

Again we see that using a ladder inspection checklist like ours is critical for ensuring you have proper conditions for ladder storage and transport.

Ensure Team Members Have Proper Training

Again, it may seem like an obvious tip, but many service companies face the issue of not properly training team members. For example, many companies will focus on training team members regarding ladder use, carrying, and working at heights.

However, few will remember to provide adequate training regarding site inspection. Therefore, we felt it prudent to note the three main areas of training required for workers who utilize ladders in their profession.

- Ladder use

- Working at heights

- Worksite Inspections

Have Team Members Document Pre-Use Inspections

Team members using ladders should document their pre-use inspections. This documentation can help ensure they catch any potential hazards and correct them before they become an issue. Additionally, it can help track the condition of ladders and ensure that any necessary repairs are made promptly.

Have a professional repair or replace a ladder if it’s damaged

Speaking of repairs, it’s best to leave repairs to the experts. Experts who understand the nature of materials (like fiberglass) will know when a ladder is unsafe to repair. They will also often offer certification of the ladder after their inspection or repair, making it a value-added service.

Use A Mobile Form Application

Using a digital reporting platform is the best way to manage your ladder inspections. A platform like 1st Reporting can help you quickly and easily create inspection checklists, track who completed the assessments, and store all your inspection data in one place. This information at your fingertips makes it easy to keep your ladders in good condition.

One of the great things about 1st is that you can use the automation within the platform to the advantage of your process efficiency. Let’s look at an example to identify one possible way you could benefit from using 1st.

Joe runs a window cleaning company. He has ten teams that drive to various clients and perform their services. Each crew carries three ladders: two extensions and a step ladder.

Joe has run into problems before when it comes to documentation, so he wants to ensure that not only are his teams safe but that they’re documented. Joe also has some junior team members at greater risk due to being new to the industry. But Joe can’t be there to guide them at all times, leaving that task to the leads of each team. But what if they forgot something? Someone could fall and be seriously injured.

Joe uses 1st Reporting and gets his team trained in a matter of minutes on how to complete their ladder inspection report on their company smartphone. There is no longer a need for a paper document, and there are no longer messy handwritten forms, either!

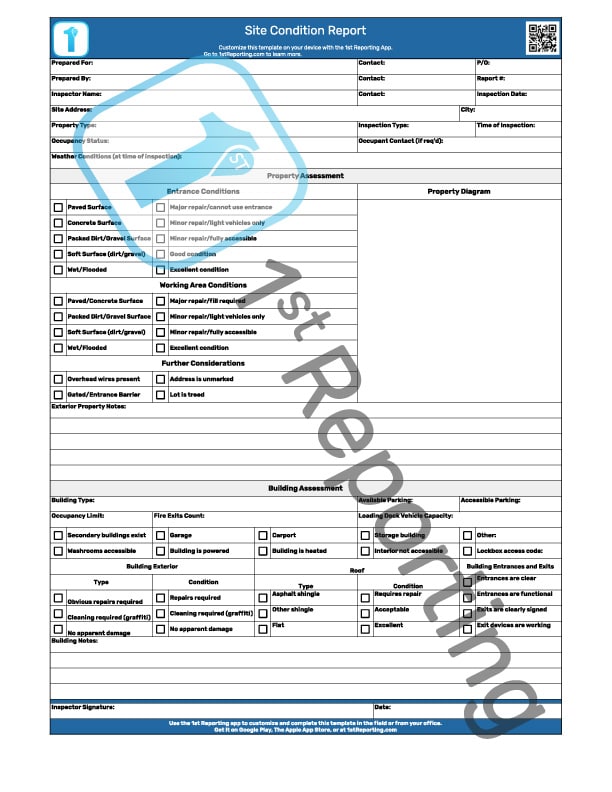

Now, Joe has instituted a regulation in his company that all road personnel must complete a ladder inspection at the beginning of each shift. Similarly, they have been notified to conduct a site inspection before beginning each job at a new client site.

Automated Notifications

How does Joe manage these regulations with mobile crews? He’s taken two minutes to set up an automated notification in 1st. So, each time a crew completes a ladder or site inspection, Joe gets an instant notification. Now, it’s easy for Joe to manage which of his teams is falling behind on completing their site or ladder safety inspections.

Multi-Device Compatibility

With instant notifications, no phone calls are needed. Furthermore, Joe can open each crew’s inspection reports and note anything they found or didn’t find. Joe can do this from his desktop, laptop, or even from his tablet or phone. That’s because the app works on almost any device: Android, iOS, Windows, and Apple (Mac) devices.

Powerful Customization

1st Reporting is helpful for much more than mere ladder and site inspections. You can use the app to manage any inspection, checklist, form, or other document. Any form you can imagine could be digitally imagined in 1st with its powerful customization features. So, you get a library of ready-made templates useful for multiple industries and the ability to make your own easily.

Dynamic Workflows

Joe loves a feature about 1st Reporting – he can customize checklists based on the ladder type. When one of his team checks off that they are inspecting a step ladder, for example, the form changes to only provide questions and responses for step ladders, excluding anything for extension ladders.

Similarly, if one of Joe’s team chooses an extension ladder, the dynamic template Joe had the team at 1st helps him set up changes exclusively to extension ladder checkpoints. That’s the beauty of a dynamic workflow – you can have it change on the fly, depending on the responses your team provides.

Finally, you can get an instant notification to let you know your team completed their inspection. The possibilities with dynamic workflows are infinite, allowing your business to use technology to better your processes and add digital efficiency to your workflows.