If you’re looking for a Hot Work Permit Template, you’ve come to the right place. We’ve created a downloadable PDF Hot Work Permit Template for tracking and managing your hot work processes. We’ll look at what’s included, some best practices, and a few tips to improve your ease of management, so stick around to the end for a few extra gems that will help improve your workflow.

A Hot Work Permit Template is a document for recording, tracking, reviewing, and managing any hot work process. Hot work permits are used for welding, metal cutting, grinding, or any other action that produces sparks or fire.

Let’s get started with what you can expect to find on the downloadable PDF template.

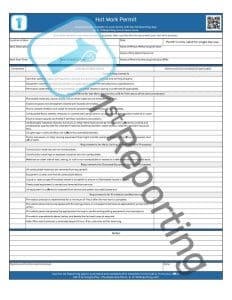

Included in the Hot Work Permit Template

The 1st Reporting Hot Work Permit (HWP) Template is based on the NFPA-recommended HWP, with a few minor changes. We’ve added a few extra points to ensure better understanding and safety from the NFPA HWP recommendations.

Our Hot Work Permit Template is conveniently segmented into seven sections to provide a workflow for completing the hot work documentation and fire watch processes. These segments are described as follows.

Administrative

Our administrative segment of the HWP has two distinct halves: The work descriptors and the names of those holding responsibilities, along with the date of the hot work process.

Two principle and fundamental ruling considerations are noted within the administrative section:

- A directive to seek alternatives to hot work or complete the form.

- A note about permit date validity.

On the work descriptor side of the segment, we’ve included the work location, description, and start/completion times. The completion time is critical to ensure fire watch protocol timing.

On the right side of the administrative segment, we’ve got an area to include the work date, which is also critical to the fire watch and monitoring protocol. Similarly, we’ve also included a place to note the names of the three individuals who hold crucial responsibilities regarding the process:

- The name of the person performing the hot work.

- The name of the person performing fire watch and monitoring.

- The name of the person responsible for issuing the hot work permit.

General Hot Work Safety Requirements

The general hot work checkpoint descriptors cover the basics of checking fire prevention equipment, hot work equipment, and obtaining permission for hot work processes. We’ve included a note regarding lined vessels, like those in the pharmaceutical, food manufacturing, or cosmetics industries, where you’ll find stainless steel pipes and vats lined with rubber or plastic.

Pro Tip: Ensure you have the appropriate GMP forms to complete a GMP audit following any work on equipment that contacts food, cosmetic, or pharmaceutical products.

Requirements For Hot Work Area

The hot work area consists of a space equal to 35 feet/11 meters radiating outward from the center point of the hot work process. In other words, the hot work zone is a 35-foot circle of space around the hot work area.

Given the proximity of this space to the hot work, there are specific protocol requirements for fire prevention. These checkpoints are all outlined within this segment of the HWP.

Requirements for Walls, Ceiling, or Roof Hot Work Processes

Structural hot work is a serious concern when building construction includes flammable materials. This segment of the HWP encompasses the checkpoints concerned with structural hot work processes.

Requirements for Enclosed Equipment Hot Work Processes

Enclosed area hot work possesses a series of specialized challenges. Aside from ensuring your team members have the appropriate enclosed space training and appropriate gas sensor safety equipment, you’ll want to ensure they are well-versed in the enclosed hot work requirements covered by this segment of the Hot Work Permit Template.

Requirements for Fire Watch and Monitoring

Following every hot work process, a minimum of 1-hour fire watch is required in most countries and jurisdictions. Several key checkpoints must fall under consideration during the fire watch protocol, and these are outlined in this segment of the hot work permit.

Notes and Sign-Off

The final section of the HWP includes an area where any responsible individuals involved might include further notes regarding the work. Similarly to other reports, a final sign-off by a responsible person assuring hot work process completion resides at the bottom of the downloadable template.

10 Best Practices For Using A Hot Work Permit

We’ve compiled some handy best practices for using hot work permits. Feel free to bookmark this page and use it to help train your team.

1. Familiarize yourself with the hot work permit template and checklist requirements before starting your project.

2. Always have a designated hot work permit issuer responsible for issuing permits and communicating with other team members regarding hot work procedures.

3. Ensure your team members know all applicable fire prevention requirements before beginning any hot work processes.

4. Verify that all necessary fire prevention equipment is in working order before commencing hot work.

5. Ensure that the area surrounding the hot work process is clear of flammable materials and combustible objects, including people.

6. When conducting hot work in an enclosed space, always follow safety guidelines for enclosed area hot work processes.

7 Keep a detailed record of all hot work processes and keep copies of the relevant permits on file.

8. Conduct a post-hot work inspection of the area to ensure that all fire hazards have been extinguished. Similarly, note that no hot work equipment has been left unattended.

9. Always follow hot work permit best practices for fire watch and monitoring, even if your hot work process is being conducted outdoors.

10. Have your hot work permit issuer sign off on completing the hot work process to verify that all guidelines have been followed.

Tips For Improving Hot Work Permit Management

You can do several things to improve hot work permit management within your organization. Improving hot work permit process efficiency and management is critical to capture some of the loss from the time and labor required for process completion. Here’s how we recommend you recapture some of these losses and improve process efficiency and management.

Standardize Procedures

Create standardized procedures for issuing, renewing, and revoking permits. This action will help ensure that all hot work permit processes are completed promptly and efficiently.

Designate One Individual as the Permit Issuer

To help streamline hot work permit issuance, we recommend designating one individual within your organization as the hot work permit issuer. This designated issuer can collect all required information and signatures before issuing a hot work permit.

Conduct Audits Routinely

Conduct routine hot work safety audits to ensure compliance with safety standards. These audits can help identify hot work permit process improvements that you can make within your organization.

– Audit hot work processes routinely to ensure compliance with safety standards

– Identify hot work permit process improvements that you can make

– Capture some of the loss from the time and labor required for process completion by defining key indicators for routine audit completion

Educate and Train

Educate team members on the importance of following hot work permit best practices. Training hot work permit issuers on how to efficiently issue hot work permits can also help improve process management.

Download Our Hot Work Permit Template

Use our downloadable hot work permit template to streamline hot work permit issuance within your organization. This template includes all the necessary information and signatures to issue a hot work permit. Simply download the template, fill it out, and submit it to your hot work permit issuer.

Implement Software Solutions

Implement a hot work permit management software system to automate the process and improve tracking and organization. You will want to try using the 1st Reporting app instead of paper hot work permits printed on paper.

1stReporting offers a digital hot work permit solution that can be used in place of paper hot work permits. Our app streamlines the hot work permitting process by allowing users to create, issue, and track hot work permits electronically.

The application lets you do many things that a paper form cannot perform. These features include:

Automated Custom Notifications – Let the right supervisor automatically get notified upon form completion.

Dynamic Form Linking – Have a follow-up process to an audit? You can attach it digitally to the audit form for a complete incident, audit, and follow-up package.

Custom Form Builder – Create the forms your organization needs (that is, if you need help finding the forms you need in our existing template library).

Teams® Integration – We’re confident that your paper forms can’t work in Teams®. However, our app can work seamlessly with Microsoft Teams®, so you never need to miss a notification of form completion, even when neck deep in the Teams® environment.

Safety should always be the top priority when it comes to hot work. By following hot work permit best practices and implementing hot work permit management software, you can help ensure that all hot work processes are conducted safely and efficiently.

1stReporting is the leading digital hot work permit software solution today. Our app streamlines the hot work permitting process by allowing users to create, issue, and track hot work permits electronically. Try 1stReporting for free today!