Excavation work is a critical area for construction project safety. To help project managers ensure their excavation sites are safe, we’ve created an excavation safety checklist based on OSHA’s available information. This guide provides an overview of the critical elements of the list, its benefits, and tips on how to use it effectively, promoting worker safety at excavation sites.

Included in the Excavation Safety Checklist

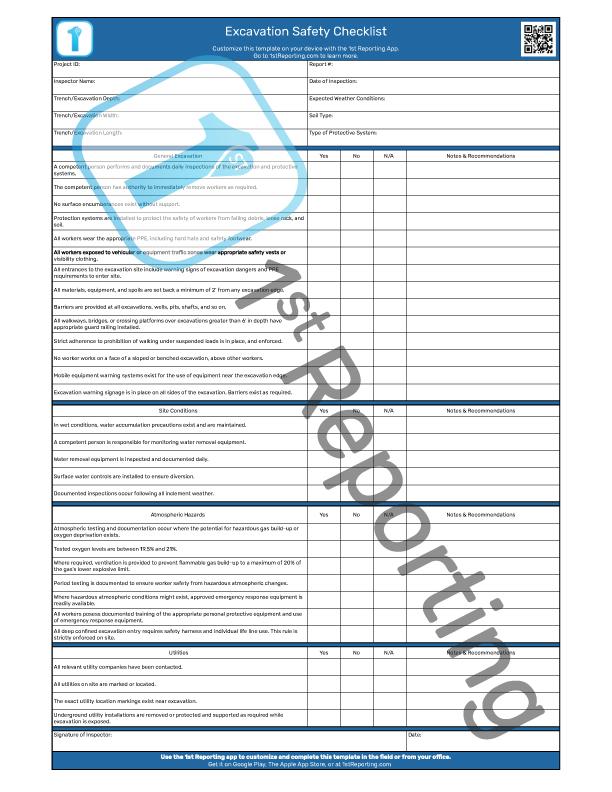

You’ll find that the excavation safety checklist has six primary sections. Each section is briefly described below for clarity. Therefore, we recommend bookmarking this page so you can share it with your team members to ensure everyone is documenting inspections with the same strategy and insight.

Administrative Section

The administrative section serves a few purposes on the Excavation Safety Checklist. First and foremost, it provides a snapshot of the excavation information, including excavation measurements, identification, weather conditions, and report number and date. You can get a quick overview of the site situation using this information. Similarly, you’ll be enabled to quickly create a filing system and keep document control to keep track of projects over time. Likewise, maintaining records (especially safety-related ones) is critical for operational safety regulatory compliance.

General Excavation Inspection

Team members must address several common inspection points during any construction project involving excavation. Further to this goal, the General Excavation section of the excavation safety checklist includes standard safety, regulatory, and other appropriate inspection items. The list has three columns, a ‘Yes, a ‘No, and a ‘N/A.’ Similarly, we’ve also included a fourth column where your inspectors may note further observations.

Site Conditions Inspection

Following the general inspection is the site conditions inspection. This portion of the excavation safety checklist includes items pertaining to wet environments and preparing for damp conditions such as rain.

Atmospheric Hazard Identification

Atmospheric hazards are some of the most frightening from a safety perspective. The reason is that atmospheric dangers like carbon monoxide, for example, are not noticeable until levels are fatal. Therefore, adherence to strict atmospheric testing is an absolute necessity with any excavation involving potential atmospheric hazards.

Utilities Locate

As you know, any excavation requires a location from the regional authority. Whether it’s an LNG line, fiber-optic communication line, or another type of underground installation, ensuring worker safety and mishap avoidance is critical to any safe excavation project.

Compulsory Sign-Off

Ensure that the Excavation Safety Checklist has been completed correctly. We typically insist that the inspector signs and dates the document upon completion. By implementing a signature requirement, you’re adding authority to the document. This sense of authority does two things. First, it empowers the inspector to do a good job. It ensures that the inspector understands the seriousness of proper safety inspection. It gives your team a greater chance of mitigating safety hazards, which is the bottom line.

How To Use The Excavation Safety Checklist

There are two ways you can use the Excavation Safety Checklist. The first is to download our template, print as many copies as you need, and disperse them to the appropriate team members, along with instructions. The second and more efficient way is to use the excavation safety checklist in our industry-standard (quite robust) template library within the 1st Reporting app. We’ll get into that more later. Let’s focus on the best practices for completing the excavation safety audit.

Always complete safety inspections before work starts.

A few caveats exist to always completing a safety inspection before work starts. The concept here is to maintain safety at all times. Therefore, there are a few times when a re-inspection becomes a requirement:

- A change in staffing (like a shift change).

- A change in conditions (like a severe rain storm rolls through).

- A change in equipment (new types or styles of safety equipment are introduced to an existing site).

- A repair completes of critical safety equipment (an excavation bracing gets replaced due to prior damage).

Never ignore inspection reports that call for repairs/work.

The worst thing that can happen is that a team member calls for a repair of safety equipment, and the request falls on deaf ears. The company would face potential legal liability should the situation backfire into an incident, and the manager with poor judgment would also be held liable. As a supervisor, it’s not good to put yourself in legal crosshairs, and it’s worse to put someone’s safety in jeopardy. Therefore, the only logical conclusion is always to follow up on safety requests.

Always follow up on repairs with a fresh inspection.

Many forget to re-inspect equipment following equipment repair. Many will assume that this or that technician or mechanic would have done so. However, when we make assumptions about safety, we open the door to disaster. Therefore, it should be a requirement at your company to always complete a safety inspection after a repair, even a minor one. This recommendation is particularly essential for construction and excavation projects where danger is often at its highest.

Tips For More Efficient Safety Inspection Management

Completing safety inspections regularly is critical to maintaining and improving safety and efficiency.

Establish Clear Roles And Responsibilities

Clearly define who is responsible for carrying out safety inspections and who is responsible for follow-up actions. Doing so will help to ensure that everyone knows what they are accountable for and that checks remain consistent.

Remember that clearly defined responsibilities equate to clearly understood responsibilities. There’s no better way to get buy-in.

Set Inspection Schedules

Establish a regular inspection schedule to ensure that inspections occur at the right frequency. Regular inspections help identify potential hazards before they become a problem and prevent accidents from happening. Prevention is always easier than mitigation, in this case.

Use A Standardized Checklist

A standardized checklist helps to ensure that team members consider all relevant safety aspects during an inspection. Standardization also helps to ensure that all assessments happen consistently and efficiently. Furthermore, standardized checklists ensure that everyone is on the same page, both those who perform the inspection and those who analyze the results.

Use Digital Tools

Consider using digital tools like mobile inspection apps to streamline your inspection process. They can help to save time, improve data accuracy, and enable you to analyze data more effectively. Furthermore, when you use an app with customized notifications, they also improve communications between inspectors and supervisors.

Ensure Good Communication

Communication between managers, supervisors, and safety inspectors is essential for effective safety inspection management. Ensure everyone knows their responsibilities and that information is shared clearly and promptly. Good communication is often a side effect of good management practices. You’ll find you get the best results when you create and maintain standardized communication practices for your team and inspire an empowering work environment.

Provide Training

Provide training to safety inspectors on how to conduct inspections effectively and efficiently. Training will help to ensure that checks are carried out consistently and to a high standard. Furthermore, training and refresher training ensures that your team members are observant of safety practices and act upon those teachings in their day-to-day activities, creating a much safer work environment for all.

Regularly Review And Update Procedures

Ensure that procedures for safety inspection management are regularly reviewed and updated. Review and analysis will help to ensure that your inspection process remains practical and relevant. Moreover, as technology changes, you may find a better-suited platform for managing your inspections, incidents, and other documentation, a platform like 1st Reporting.

Use 1st Reporting

Consider using 1st Reporting, a robust inspection app that empowers admin-level users to create custom templates for inspections, incidents, audits, or anywhere you need a form or checklist. The digital app works on multiple platforms, so it’s great for field teams and organizations with multiple remote sites or crews. Using 1st Reporting can help to streamline your inspection process and enable you to analyze data more effectively.

Furthermore, 1st Reporting’s powerful features (like report GPS functionality and customizable notifications) mean your organization can get ahead of the competition. Similarly, adding automation to simple communication processes can significantly increase productivity, efficiency, and, most importantly, safety.