Arc flash suit inspection is critical in providing adequate protection for electricians working with high-voltage equipment. Regulations state that regular equipment inspection is mandatory, so we recommend utilizing an efficient system to inspect and document observations.

We’ve created a downloadable arc flash suit inspection checklist to help you get your arc flash inspection program off on the right foot. The checklist will guide you and your organization to ensure compliance with regulations and, of course, attempt to provide the safest conditions for your team.

In this guide, we’ll go over the basics of arc flash regulatory compliance and inspection. We’ll provide you with crucial measurables and actionable advice to add greater efficiency to your existing health and safety programs, so grab your checklist download, a pen, and paper, and let’s get started.

The Fundamentals of Arc Flash Suit Inspection

Let’s get to the point: if you or your team aren’t entirely familiar with the fundamentals of arc flash and PPE requirements, then a quick refresher could save someone’s life. Even the most experienced can forget one of the basics, so it’s best not to skip this brief refresher.

Risks of Arc Flash

Simply put, arc flash is the event of electricity leaping from its intended path and crossing the air to its preferred path. That preferred path might be you or a team member, so you shouldn’t take it lightly.

Arc flash is mini lightning. That’s right, and it can reach temperatures of 35,000 degrees Fahrenheit (19,000 degrees Celsius). Keep in mind that the surface of the Sun is estimated to be 9,932 degrees Fahrenheit (5,500 degrees Celsius). (source)

The summary of risks? Arc flash is deadly. Never take it for granted.

Arc Flash vs. Arc Blast

We’ve defined how an arc flash is like small lightning. Arc blast, however, is the same except that it includes a supersonic shockwave when the electricity vaporizes metal conductors.

Typical arc flash PPE is not suited or suitable to withstand an arc blast that can send molten metal and other debris flying at frightening speeds along with the heat and light of the arc flash that typically comes with the explosion. (source)

This guide will focus on the PPE requirements for arc flash only, not arc blast.

Arc Rating & PPE Requirements

We can define arc rating as the value given to PPE (typically clothing) as the material’s ability to withstand exposure to an electrical arc discharge.

Each component of the personal protective equipment utilized must adhere to specific ratings based on the category requirement. The categorical requirements use some fundamental principles of electrical safety relating to arc flash distance and severity in determining the PPE rating required. If I am to simplify, the following table will guide you through the fundamentals, but I’m sure your certified electrician can explain them in greater detail.

Please note that the arc rating of PPE should correspond to the required category at a minimum. It’s okay, and you are even encouraged to upgrade your PPE to a higher-tiered class for extra safety.

NFPA/OSHA Regulated PPE Requirements

There are four arc flash PPE categories. Each category is based on an established rating system that uses a minimum arc rating of cal/cm2 or calories per centimeter squared. It may seem like an odd rating, but it defines the maximum amount of heat that a material can withstand to protect the wearer against second-degree burns. This measure does not mean the wearer won’t receive second-degree burns in the case of an arc flash; it only means that the material will help to reduce second-degree burns.

An arc flash’s energy is calculated using a unique formula. We won’t get into that here today, but your electrician can answer questions about that formula. Let’s look at those PPE requirements based on the protection category against arc flash hazards.

| PPE Category | Min. Arc Rating | Clothing Required | Face/Head Protection | Hand/Foot Protection | Other PPE Required |

| 1 | 4 cal/cm2 | – Long sleeve shirtFull-length pants or arc-rated coveralls – Jackets or exterior covers must be arc rated | – Arc rated wrap around face shield with rated hood or coverings (balaclava) | – Heavy non-conductive gloves (leather) – Plastic cap-toed (electrical rated, generally not steel-toe) boots or shoes | – Eye protection – Hard hat with rated liner – Hearing protection |

| 2 | 8 cal/cm2 | – Arc rated long sleeve shirt – Arc-rated full-length pants or arc-rated coveralls | – Arc-rated full hood – Arc-rated face shield (usually built into hood) – Arc-rated balaclava or similarly rated covering | – Heavy non-conductive gloves (leather) – Plastic cap-toed (electrical rated, generally not steel-toe) boots or shoes | – Eye protection – Hard hat with rated liner – Hearing protection |

| 3 | 25 cal/cm2 | – Arc-rated jacket and arc-rated pants or arc-rated coveralls | – Arc-rated full hood and face shield | – Arc-rated gloves or rubber insulated heavy-duty gloves with leather glove protectors – Plastic cap-toed (electrical rated, generally not steel-toe) boots or shoes | – Eye protection – Hard hat with rated liner – Hearing protection |

| 4 | 40 cal/cm2 | – Arc-rated jacket and arc-rated pants or arc-rated coveralls | – Arc-rated full hood and face shield | – Arc-rated gloves or rubber-insulated heavy-duty gloves with leather glove protectors. – Plastic cap-toed (electrical rated, generally not steel-toe) boots or shoes | – Eye protection – Hard hat with rated liner – Hearing protection |

You can also have your electrician perform an arc flash study to determine the risk and required PPE, should you not care to follow the PPE categorization methodology set out by the NFPA.

Inspection Periodicity

Your team should conduct inspections on a scheduled and regular basis. The PPE equipment inspection must include the following schedule at a minimum:

- Daily/Before Use

- As per manufacturer recommendations (some rated fabrics last only 12 to 16 months while others can last up to 4 years depending on the material and manufacturing process). (source)

- At a minimum, electrical and flame specialized testing every six months. Have a qualified test facility perform the tests. Usually, the suppliers for this specific PPE will have their test facilities or arrangements with other companies that can complete these tests and certifications of the equipment on your behalf. (source)

Other Important Related Time and Scheduling Items

According to NFPA 70E, Your relevant must complete article 110.2.D.3, training and refresher training at least once every three years.

Arc flash risk assessment needs completion when the circuit is renovated or repaired. Similarly, Your team must complete a regular arc flash risk assessment schedule at least every five years.

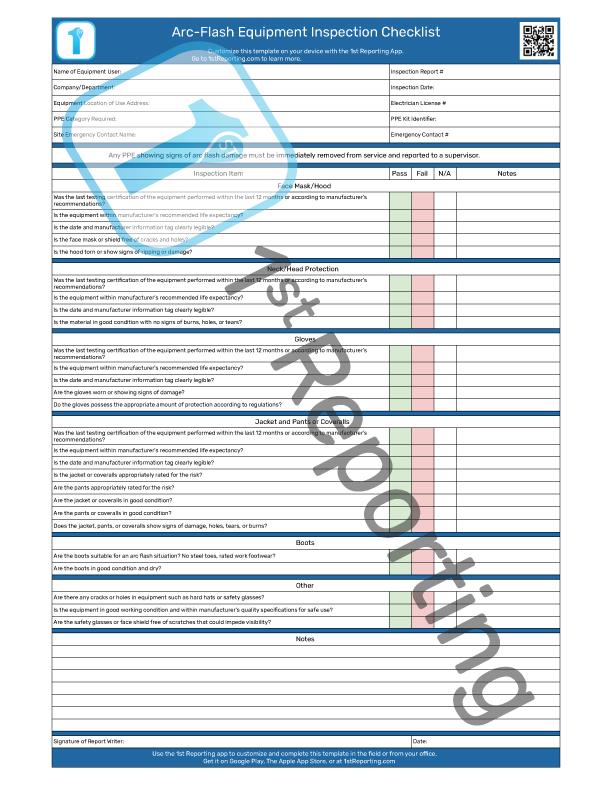

Included in the Arc Flash Suit Inspection Checklist

We’ve conveniently segmented the Arc Flash Equipment Inspection Checklist into eight sections.

Administrative – The administrative section includes vital information regarding the inspected equipment and some information about the work requiring the equipment.

Face Mask/Hood – Beginning with the face. This section asks the most pertinent questions about the face mask and hood.

Neck/Head Protection – The neck and head PPE section addresses the related inspection questions.

Gloves – Gloves are essential because the hands are typically closest to arc flash risk. For this reason, gloves get their section on our checklist.

Jacket and Pants or Coveralls – Jackets and pants are interchangeable with coveralls, so we’ve included these in one section for your convenience.

Boots – Although we may not think much of footwear for arc flash scenarios, footwear can insulate our bodies from being grounded. Therefore, an inspection of footwear before entering electrocution hazard areas is essential.

Other – This section covers remaining items like a hard hat, safety glasses, hearing protection, and other required PPE.

Notes and Sign-Off – Allowing the inspector to add any extra notes and sign off on the inspection report is a critical stage of controlling information and personal responsibility.

Best Practices For Arc Flash PPE Inspection and Care

Understand Approach Boundaries

Approach boundaries are the distances determined by the NFPA. These boundaries include the following.

- Flash protection boundary – The flash protection boundary is where a team member wearing PPE receives second-degree burns if an arc flash occurs.

- Limited approach boundary – The distance from exposed live components to a limited safe approaching distance when using full-rated PPE.

- Restricted approach boundary – A highly increased risk zone of approach at a distance calculated based on the arc flash potential.

- Prohibited approach boundary – A distance from a live, exposed component will likely result in arc flash or electrocution risk. Typically it is considered the same risk as direct contact with live parts.

Remember that each piece of electrical equipment may have different approach distances based on configuration. Therefore, we cannot establish a uniform and typical distance, and you must calculate approach boundaries on a case-by-case basis. (source)

Keep a Dedicated Arc Flash PPE Cabinet

One of the biggest challenges to maintaining PPE is keeping it safe and in good condition. Many workers toss PPE around their work trucks like it is junk. With this specialized equipment’s cost and testing requirements, it isn’t worth letting your team run rampant with their PPE. Ensure your service crews maintain the equipment in a neat and orderly fashion. Keeping your equipment in a specific location, like a dedicated PPE cabinet in an office or work vehicle, is strongly recommended.

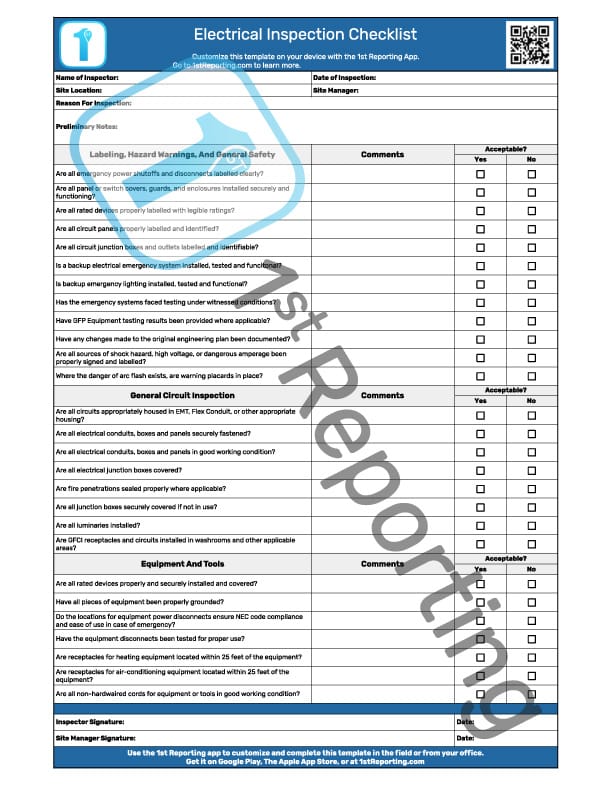

Improve Your Inspection Process

The best thing you can do to improve your inspection processes is to add a tool that allows data capture, mobility, and ease of report management in one place. Until recently, a solution hasn’t been on the table with enough gusto to get the job done well. However, we’ve created the ultimate tool for organizations like yours: The 1st Reporting App.

Before you turn away, consider this: Using a paper form is fine, except that it’s thousand-year-old technology and keeps your team working in the past. It also maintains your reliance on your team to write neat and coherent reports. Oh, and don’t get me started on the costs of printers, ink, paper, filing cabinets, and the real estate needed to hold such monstrosities.

In an age where everyone and their relatives have smartphones, and many of us provide them to our team members as a part of their work equipment, why are we still using paper? Let’s give the trees and our wallets a break, shall we? Many features will benefit you and your team that paper forms can’t compete with or compare. Here are a few benefits you can’t ignore:

Custom Form Creation

Paper forms were so yesterday, weren’t they? Have you ever spent time designing or had a team member spend time developing a template, printing it, and then discovering a mistake? How about updating or changing forms due to regulation or equipment changes?

There are several scenarios where we need to update or address changes to our inspection processes, and if you’ve got a big organization, it can be a big headache. Save a ton of time using a digital reporting platform like 1st Reporting that provides custom form-building controls.

With the custom form builder available to administrators using 1st Reporting, you can ensure your team has the perfect form, updated as you see fit. In fact, with the custom builder, you can create any form you can imagine and make it just the way your team needs it.

Custom Notification Control

Having a team member complete an essential inspection or another task using a checklist or form of some type is excellent for maintaining consistent workflows. Knowing the moment, they finish the form is even better.

Using 1st Reporting, you can customize notifications so that the right person receives notifications in real-time when a team member completes a specific report of your choice. This automation makes the communication process more straightforward and lets you keep control over the daily activities that matter most.

GPS and Locational Map View

Managing multiple teams, reports, inspections, and even locations is a headache. However, we’ve solved that at 1st Reporting by creating an easy-to-use manager’s report dashboard that includes customizable map views.

You can see all your team’s reports by location and sort them accordingly. It makes managing field crews much easier and less time-consuming, making your job easier and more efficient.

Teams® Integration

Do you use a platform like Microsoft Teams® and want to get your 1st Reporting notifications in your Teams® dashboard? No problem. 1st Reporting is at your fingertips with Teams® integration built-in.

Dynamic Process Customization

One of my favorite features of 1st is the ability to create custom forms and checklists that use dynamic properties to adapt. Very cutting-edge stuff and a literal magic trick if a piece of paper could accomplish such a task.

Imagine you could set up dynamic workflows using forms like a checklist to guide team members through complicated tasks. And those steps could dynamically change based on the team member’s input. The possibilities are endless, and what you could do to improve team performance and efficiency.

Still not convinced? Try a Free Trial, or even better, let us guide you through the app by booking a demo with our team.