Daily vehicle inspections using an operator walk around inspection checklist are crucial to maintaining safe vehicles and thus safe roads, job sites, and facilities. Whether driving a big rig or a forklift, performing a vehicle walk-around and inspection before use is not only crucial, it’s often legally mandatory.

A proper vehicle and equipment walk-around checklist is essential for vehicle and equipment operators to complete their pre-inspection safety check. With the 1st incident Reporting downloadable template, you can print your generic vehicle or equipment checklist to use with your fleet.

If you are looking for more of a digital solution, then keep reading. We’ll discuss some digital solutions you can take advantage of today if printing a hardcopy checklist isn’t your cup of tea.

But, let’s start things off with an introduction to our free, downloadable PDF template and how to use it. Then we’ll continue by discussing how this template could find usefulness to your company; and the benefits of having an organized and uniform process for vehicle and equipment inspections.

Lastly, we’d love to share some tips about the vehicle and equipment walk around. As well, we’ll share a fantastic method of doing the whole process digitally to avoid the need to print.

Included In The Vehicle/Equipment Walk Around Inspection Checklist

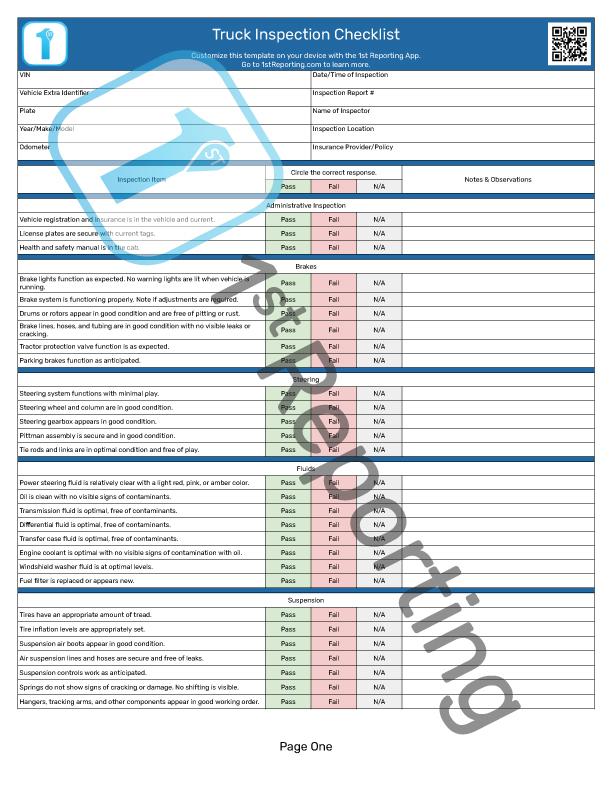

The Vehicle / Equipment Walk Around Checklist consists of three primary sections, the administrative data, the vehicle walk-around information checklist, and the sign-off portion of the checklist template. These three sections include:

- Data about the checklist, including

- Company name

- Driver name

- Date

- And more

- Pertinent safety information

- Licensing information

- Basic equipment controls test and other equipment systems checks

- Two blank areas to write your equipment specific requirements

- Sign off for the driver/inspector

How To Use The Operator Walk Around Inspection Template

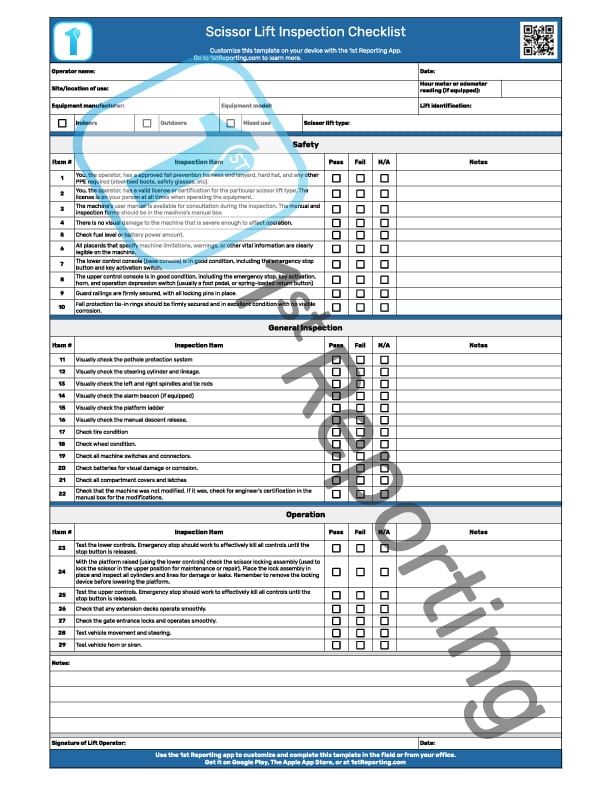

Operating a business in Canada, The US, or many other countries where operational equipment and vehicles are a part of the job comes with specific requirements. For example, in Canada, a company that utilizes aerial lift equipment must meet specific inspection requirements for that equipment to be used safely and in accordance with legislation. The CSA has very specific rules regarding the inspection of such devices (B354.2-01 for scissorlift platforms and B354.4-02 for boom-type aerial platforms). (source)

The Vehicle and Equipment Walk Around (VEWA) checklist (Operator Walk Around Inspection Checklist) is intended as a general use template to use for various types of operating equipment and vehicles. Your company could use the template to suit a daily pre-operation walk-around inspection that most countries, provinces, and states require an operator to perform before use. We’ll assume this is your intent and carry on with that assumption for the remainder of this example procedure for using the checklist template.

Here are the simple steps we recommend for completing the daily vehicle or equipment walk-around inspection.

- Download and print your copy of the vehicle/equipment walk-around checklist template.

- Complete the administrative section of the template, noting all pertinent information about yourself and the equipment. Remember that it should be the equipment or vehicle operator who completes the inspection.

- Start working through the items in the checklist. Do not skip any items and if your specific equipment has extra components to check, like guard rails or an attachment, then use the spare sections to include these additional specialized checks.

- If the equipment or vehicle requires some sort of repair, complete the other notes section. It might include observations about damage to the equipment that may not render the equipment un-operational but should be noted to show that the operator is aware of the damage pre-operation. It can keep an operator out of blame’s gaze if someone others are unaware of the damage. Similarly, you can use this space to note anything from recommended improvements to recommended repairs or service to the vehicle or equipment.

- Lastly, when the inspection is complete, the vehicle or equipment inspector should sign off on the document. It shows that the operator did all due diligence to ensure the inspection was completed correctly.

Benefits Of Daily Vehicle And Equipment Inspections

Aside from the obvious liability issues with the operation of equipment or vehicles for a business, it is vital to complete inspections of equipment before use. Here are a few key benefits from a daily or pre-use inspection of vehicles and equipment:

- Safety – Catch potential equipment hazards before they cause an incident like an employee injury or a dangerous situation.

- Reduced Maintenance Costs – You can catch many potential breakdowns ahead of time by thoroughly inspecting equipment. Noticing things like fluid leaks or even seeing something irregular can set a red flag to look deeper into an issue. These issues are often a failed part or pre-failed component that is leaking or apparent. Catching parts about to break before they fail can save hundreds or even thousands in repair costs before a catastrophic failure event with the equipment.

- Reduced Operating Costs – When you catch equipment issues before failure, contingency plans can come into action before your operations are affected. For example, suppose you know your only forklift needs a hydraulic line repair. In that case, you can rent equipment to cover your operational needs before the equipment fails and leaves your operations empty-handed. The potential savings on your operations by averting an unexpected equipment failure can be massive.

Tips For Effective Vehicle And Equipment Inspection And Reporting

The best method to prepare your staff and equipment for daily operations is to be prepared for emergencies. A part of that preparedness is the completion of inspections to ensure safety and compliance with operational requirements and legislation concerning the use of vehicles and equipment. Let’s look at a few key ideas you can implement to have a more practical vehicle and equipment check process.

- Never skip an inspection. Even if your staff drove the equipment the day before, they ought to treat every day like it was equipment you haven’t seen before. This way, no one forgets to check equipment, and therefore, your company maintains a structured and consistent walk-around procedure.

- Never skim over items in the checklist. People tend to skip over the familiar. It’s true for equipment and vehicle operators, just as it is true for you and everyone else. Ensure your staff doesn’t skim over items by doing random spot checks on their completed checklists.

- Keep equipment and vehicle training up to date. When licensing is not a legal requirement for a specific equipment operation, many companies will cut corners on proper training. Even companies operating equipment that requires licensing have been known to speed through training with a lack of regard for the actual training process. Don’t see training and refresher training as an expense that is not required. It could be the difference between attending a funeral for your staff or not. Keep them safe, keep them trained.

A Digital Solution For Operator Walk Around Inspection Checklist

You are free to download and use the VEWA Inspection Checklist Template for all of your business needs. However, what if there were a more efficient and eco-friendly solution? There is, and it involves using a digital reporting solution like the 1st Incident Reporting App.

The app is versatile and customizable field reporting software that works on any Android or iOS device. Available on the Google App Store and the Apple App Store, you can use the app from any location with any number of devices to complete your vehicle walk-around checklist on the fly – digitally.

Saving you time and printing expenses, as well as filing time and space, can save your company money for your vehicle and equipment operating expenses. And your vehicle and equipment operators need only carry their company smartphones or tablets with them on the equipment to maintain carrying a copy of their inspection report. It satisfies the need to comply with legislation that states the inspection must be available by the operator should a bylaw or other enforcement officers arrive on site. And as most companies require their staff to carry company phones anyway, it’s a simple way to maintain legal requirements without worrying about carrying around extra paperwork.

Digital checklists not only prevent losing vital paperwork but also help maintain records in an orderly manner. Take equipment like forklifts or scissor lifts that are often used outdoors. Maintaining written checklists outdoors can be a challenge on the best of days. From wind to rain to snow, many inspection reports are ruined on equipment used in the elements. But a digitally completed checklist will never be wrecked by the elements once submitted to the company account.

You can also retrieve digital reporting documents at a few seconds’ notice. No need to dig through files and cabinets to find a specific report. The way you can organize and retrieve digital checklists and reports makes the time savings for retrieval invaluable.

To read about more of the great features, from instant notifications to customizable forms, reports, and checklists, take a look at our app here.

Sources

- The images in this article are courtesy of Farm 6 Media and Shutterstock.

- Sparta Engineering, How Often do Aerial Lifts Need to be Inspected in Canada?, https://www.spartaengineering.com/how-often-do-aerial-lifts-need-to-be-inspected-in-canada/ Accessed March 23, 2021.

- OSHA, Working Safely With Scissor Lifts, https://www.osha.gov/sites/default/files/publications/OSHA3842.pdf, Accessed March 23, 2021.

- Canadian Centre for Occupational Health and Safety, OSH Answers Fact Sheets – Platforms – Bucket (Aerial Devices), https://www.ccohs.ca/oshanswers/safety_haz/platforms/bucket.html, Accessed March 23, 2021.

- Shell, Simple Daily Vehicle Checks Save Lives, https://www.shell.com/business-customers/shell-fleet-solutions/health-security-safety-and-the-environment/prevention-not-cure.html, Accessed March 23, 2021.