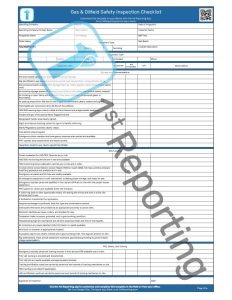

Gas and oilfield safety inspections are critical for maintaining a safe working and operating conditions in the field. The oil and gas extraction industry has its fair share of hazards, but luckily you can avoid most with some critical planning, innovative training, and regular safety inspections. To help your business maintain the utmost safety and regulatory compliance, we’ve created the ultimate Gas and Oilfield Safety Inspection Checklist based on OSHA standards and requirements. It’s the perfect tool to help your team stay on top of preventive action and dispense with accidents and injuries through intelligent prevention.

A Gas and Oilfield Safety Inspection Checklist is a critical tool required by all gas and oilfield extraction companies to assure OSHA compliance and, more importantly, safe working conditions for workers. Our checklist is free, downloadable, and ready to print and use in the field today.

In this guide, we’ll review the basics of the Gas and Oilfield Safety Inspection Checklist. We will check some of the best practices and reveal a perfect solution for maintaining strict adherence to safety, inspection, documentation, and trend analysis. Let’s get started.

Included in the Gas and Oilfield Safety Inspection Checklist

The Gas and Oilfield Safety Inspection Checklist is composed of multiple segments to maintain a uniform and standardized inspection process. We’ve briefly outlined each section below to aid in training and inspection process recognition. Feel free to bookmark this page to help train your team on inspection protocol. Here’s an outline of each segment:

- Administrative Information – The vital information detailing the operating company, rig identification, location, and further details to help organize inspection reports.

- Signage and Communications – One of the essential aspects of any workplace is the communication of hazards. This section provides coverage of proper signage communicating threats and area requirements.

- Site/Location – General site inspection points regarding the site conditions.

- PPE, Safety, and Training – As critical as hazard communications are the protective equipment and training to face hazards.

Location Specific Segments

The following three segments of the Gas and Oilfield Safety Inspection Checklist are directed to specific areas within the site.

- Mud Pump Area – Section-specific inspection points.

- Mud Mixing Area – Section-specific inspection points.

- Mud Tanks and Pits – Section-specific inspection points.

- Material Handling Equipment – Specific inspection points regarding forklifts and/or other material handling equipment.

- Generator and Electrical Systems – Compiling critical information regarding the electrical systems of the site, this section holds all the vital inspection checkpoints needed to maintain safety.

- Fire Protection – Fires are one of the most critical and hazardous incidents possible at any gas or oil extraction site. This section provides the appropriate inspection points to aid in fire prevention on site.

- Fuel and Flammables Storage – Like fire protection, fuel storage and handling are critical to on-site safety.

- Pipe Racking Area – Another section-specific segment of the checklist, the pipe racking area, requires specific inspection attention.

- Blow-Out Prevention – This section includes critical inspection points regarding all blow-out equipment and procedures.

- Derrick and Substructure – Section-specific inspection points.

- Drill Area – Section-specific inspection points.

- Hand and Power Tools – Due to spark and fire hazards, hand and power tools require unique grounding and attention at all flammable material sites.

- Hoisting Equipment – Hoist equipment is required at oil and gas extraction sites for operations, and this section includes critical inspection points regarding this equipment.

- Stairs, Ladders, Handrails, and Guardrails – Section-specific inspection points.

- Drilling Rig Vehicle – Any vehicles on site that utilize fossil fuels as a power source have specific requirements to ensure spark and heat arrestors are installed to avoid potential fire incidents.

- Hot Work – Again, dealing with fire prevention, hot work procedures on a gas and oil extraction site pose incredibly hazardous conditions. This section deals with those critical inspection points about hot work procedures.

- Water Borne Operations – Section-specific inspection points for waterborne operations.

- Confined Spaces and Hazardous Environments – Just like raised work platforms and working at heights, confined spaces pose hazardous conditions. Oil and gas extraction often includes H2S and other dangerous gasses.

- Explosives and Perforating Operations – As you understand, explosives and perforating operations pose extreme risks. This section delves into the inspection points critical to managing explosive and perforation procedures.

Special Operations and Procedures

The following segments are specific to special operations and practices utilized in gas and oil extraction operations.

- Special Operations

- Wireline Service and Swabbing Operations

- Stripping and Snubbing Operations

- Drill Stem Testing Operations

- Acidizing, Fracturing, and Hot Oil Operations

- Cementing Operations

- Air, Gas, and Mist Drilling

- Hot Tapping and Freezing Operations

- Coring Operations

- Continuous Coiled Tubing Operations

- Well Evaluation and Testing Operations

How To Use The Gas and Oilfield Safety Inspection Checklist

The concept behind using our Gas and Oilfield Safety Inspection Checklist is to maintain the highest safety standard. Secondary to this is compliance with regulatory requirements.

Our downloadable checklist is based primarily on OSHA standards. Further inspection points might be necessary depending on your site-specific conditions and regional regulatory requirements, so we recommend confirming inspection points against local regulations. However, if OSHA standards are enforced on-site, our checklist should work well to help your team prepare for OSHA official inspections.

We recommend the following procedure to make the best use of our downloadable checklist.

- Download and print the 13-page safety inspection checklist.

- Review inspection points with authorized responsible personnel trained appropriately to perform the inspection.

- Communicate with all area personnel about the upcoming inspection date and requirements.

- Compile safety procedures for each inspection phase and ensure safety compliance occurs.

- Complete the inspection checklist, noting all observations in the provided spaces.

- Review inspection findings with your team and prepare resolutions for items that require further attention.

Solutions For Efficient Inspections and Trend Analysis

Completing a paper inspection report is wise, but if your team tends to get more oil than ink on the paper, you might want to look at different solutions. Luckily, we’ve got just the thing to help you remove the paper from your operations and step into the digitally efficient future of inspection documentation.

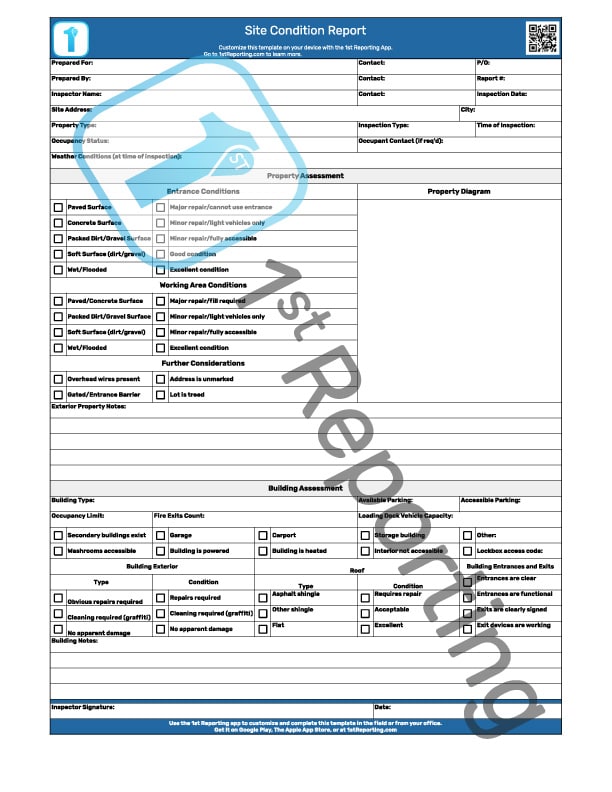

Let’s get to know 1st Reporting – an application we created to replace paper forms and checklists efficiently. It’s an app that works seamlessly with your company’s computers, smartphones, tablets, and laptops to provide your crew with a robust digital reporting platform. Our app even works with the Microsoft Teams® environment, so you don’t have to worry about missing a custom notification you set to let you know when your team completes a report.

Efficient Solutions for Modern Organizations

Paper is thousands of years old. It’s served its purpose well, but paper forms can’t dynamically change based on user input, can they? And paper forms don’t have the GPS functionality of our app, nor do they possess the convenient report management portal where you can view report completion locations on the map view of your choice. Paper, we like you, but your services are no longer required.

Experience the convenience of digital reporting with custom reports and forms you can create in the 1st form builder – so every form and every checklist is precisely the way you want it. Also, our app uses the latest cloud computing technology, so your report creators, inspectors, and team members can use the report seamlessly from anywhere. If they don’t have a stable internet connection, it’s no problem, and they can still complete a report in the app on their device. Once their device acquires a stable connection, it will upload the locally-stored form information to the secure cloud. That way, you never have to worry about team members’ incomplete reports due to internet connectivity.

Trend Analysis Made Easy

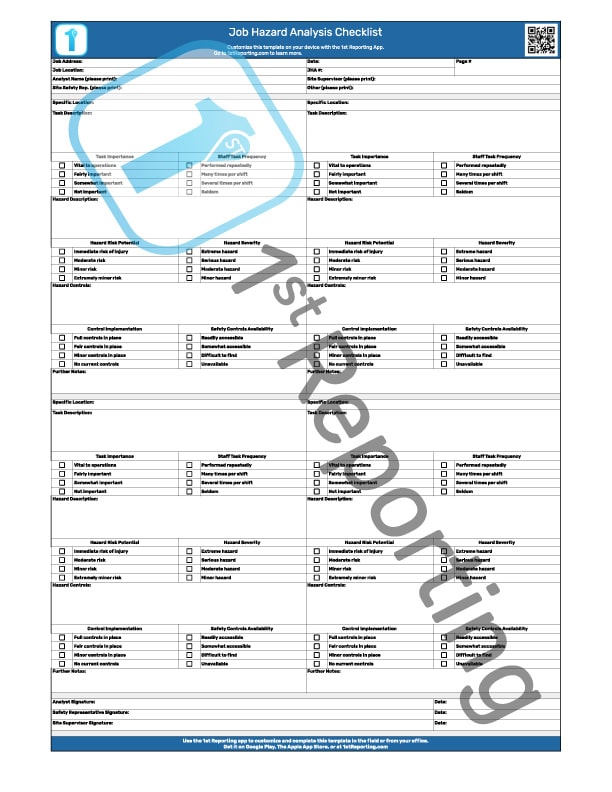

You may have realized how robust our 13-page inspection checklist is compared to others in the industry. However, if you don’t enjoy reviewing page after page of dirty paperwork to discover trends in your operations, you may consider trying our app, 1st Reporting.

Completing trend analysis on multiple extensive reports and documents is a laborious process most of us cringe at, at the best of times. Furthermore, you need a digital solution if you have various audits to review or if time is of the essence. Unfortunately, our checklist can’t help with trend analysis if you use a printed paper version of our Gas and Oilfield Safety Inspection Checklist. But while we’re here to help you, let’s discuss the solution to your trend analysis dilemma. Again, let’s see how our app, 1st Reporting, can save you hundreds of hours of combing through paper reports and documents.

Completing reports digitally using our 1st Reporting platform is straightforward. The system is easy to implement and even easier to train team members to use. These are essential points, but our app simplifies the trend analysis process. With the latest technology, our app easily combs through data so you can quickly generate the reports you need – and easily identify trends in your operations.

Please don’t take our word for it. Try the 1st Reporting solution for yourself and learn first-hand why many organizations are turning to 1st for their reporting requirements.