Generators are standard equipment on many job sites, trucks, and facilities. Used for power generation, from everything like a backup building power system to a welder’s power source, people use generators worldwide to create the power we need, when and where we need them. As generators are critical to operations, it’s vital to ensure that they are correctly inspected before use and routinely.

An inspection checklist for safe generator operation is key to proper equipment maintenance. Generator inspection checklists, like the one we have here for you to download, are challenging to find for adequate generator inspection and maintenance. That’s why we’re providing you with a comprehensive solution for your generator inspection needs.

In this guide, you’ll learn the best practices for generator inspection. We will discuss strategies to strengthen your maintenance programs while saving you time and money. Sounds too good to be true? Well, it’s not, so stick around and find out how we’ll help you transform your inspections and dramatically improve equipment life. Let’s get started.

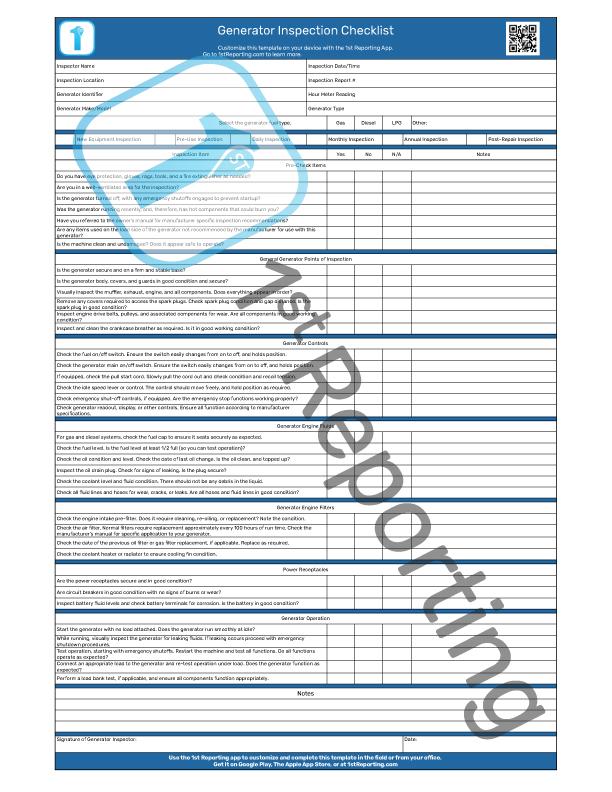

Included in the Generator Inspection Checklist

Our Generator Inspection Checklist has nine distinct sections to help guide your inspection to ensure all relevant information finds its way into your report. To help train your inspectors, you’ll find a brief breakdown of each section on the checklist.

Administrative Section

The administrative section of the checklist provides you with a place to note vital information about your inspection and the equipment. This section lets you get a snapshot of the equipment vitals while simultaneously providing a means to organize your inspection notes via the header data.

Pre-Check Items

The pre-check for the generator inspection includes a few safety items and other items that the inspector should consider before beginning a more in-depth analysis. Similarly, the points recommend waiting for the engine to cool down before commencing the inspection to avoid possible injuries like burns.

General Generator Points of Inspection

Every generator maintains specific items that don’t fit into other categories. Such as how the generator mounts and visually inspect items like the muffler. This section also includes a few random things, including spark plugs, which similarly do not fit into the following categories.

Generator Controls

Control inspection and testing are essential to the generator inspection. After all, generators are vital equipment that we must ensure operates appropriately. The generator’s switches, knobs, dials, and other instruments control that operation. New-generation generators include digital readouts and troubleshooting technology, making the inspection process more straightforward. That is until troubleshooting is required.

The generator controls section of the checklist provides some preliminary questions your inspection needs to consider regarding operable controls of the equipment.

Generator Engine Fluids

They say that the oil is the lifeblood of your car. Generators that burn fossil fuels are no exception to this saying. Fluids provide our generators with fuel, lubrication, and cooling, all desperately needed to maintain operation. This section of the inspection checklist for safe generator operation includes the vital fluids used in most modern generators.

Generator Engine Filters

We mentioned the importance of fluids to the operation of your generator. Similarly, those fluids, and even the air intake, must pass a filter to ensure cleanliness. Modern generators are equipped with several filters, from air to gas filters. Depending on the filter type and use, these filters will require periodic maintenance, cleaning, lubrication, or replacement. Consult your generator user manual for the specific requirements for your make and model.

Power Receptacles

Power receptacles include those intended for plugging in extensions as well as those that feed major power lines to banks and other equipment. We recommend that these receptacles face inspection while the equipment is off and powered down. Electrical charges can cause severe or fatal injuries, so ensure that power dissipation occurs before the examination.

Generator Operation

For the final stage of the generator inspection, the inspector will have to power up the equipment. Assuming the review deems the equipment safe to operate, the inspector should check all functions on a load and off. We recommend that only qualified personnel perform any inspection on the equipment, especially if in operation.

Notes and Sign-Off

As we find with most inspections and reports, there is an area at the end for further notes and observations. To provide validity to the information, we’ve also included a place where your inspector will sign their signature upon inspection report completion. This sign-off is vital to ensure that inspectors take the inspection seriously and provide the best, most informative, and truthful observations.

How To Use The Generator Inspection Checklist

The Generator Inspection Checklist is straightforward to use. You must download the template, print and copy the checklists you need for your equipment, and train your team to use the document.

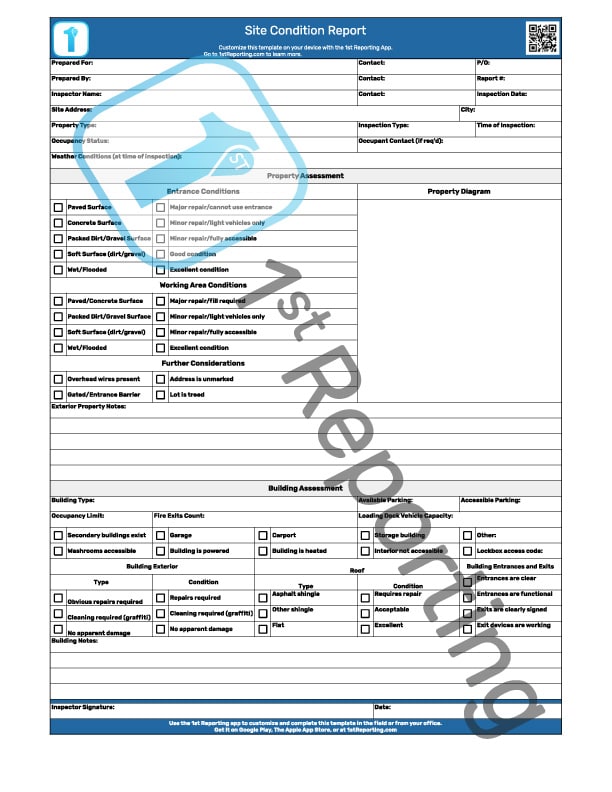

Implementing a safety checklist to inspect the work conditions is also a good idea when using any type of equipment, like a generator. Similarly, you will want to ensure that your team members have the appropriate training and possible certification for the safe and effective use of the equipment. When the generator is welding, it is essential to ensure that only qualified personnel use the equipment and perform inspections.

If welding is the name of your game, we recommend you also pair this checklist with our Hot Work Permit Template and follow our Manager’s Guide To Hot Work Permit Requirements.

Generator Inspection Frequency

We recommend that you inspect your generator(s) frequently and that the frequency varies depending on operational use. For example, let’s take a fleet of service technicians who maintain generators for welding purposes. For example, equipment (like the Lincoln Outback 185 or the Ranger) must have regular inspections and maintenance. Here is a fundamental frequency for portable generator inspections:

- New-Equipment Inspection – Always test new equipment before sending it to the field or a job site.

- Pre-Use Inspection – Always test older equipment before use.

- Daily, Monthly, and Annual Inspections – Set up routine inspections based on how often the equipment operates.

- Post-Repair Inspection – Always test equipment post-repair to ensure repairs are adequate.

Strategies For More Efficient Equipment Inspection

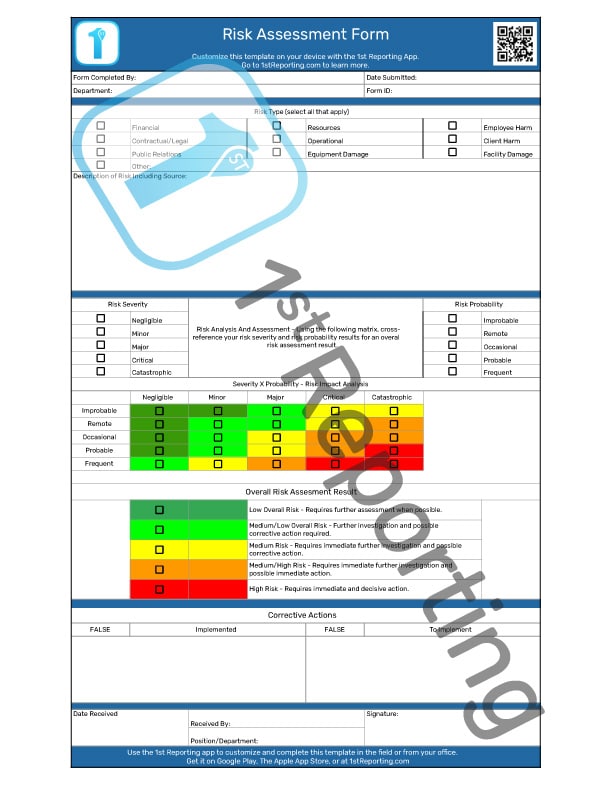

It would be best to focus on a few things to improve your equipment inspections. Let’s look at some ways you can enhance inspection processes for equipment like generators.

Use A Checklist

When an inspection is complex, it’s almost certain that with a checklist, team members will be able to see items. Everyone can have an off day, no matter how much training you provide. However, an off-day can miss essential items and bring your operations to a standstill if you’re dealing with critical equipment like a generator. Due to the complexity of inspections and the possibility of life throwing a wrench into your plans, we recommend using a checklist.

Checklists ensure that every critical component receives the attention it deserves. Similarly, a list also provides that if your team member is having an off-day, the checklist can act as their safety net to ensure they maintain procedural compliance.

Training Is Critical

With the proper training, even the best-planned checklists and inspection reports can go smoothly. One of the best practices to ensure that generator inspections are compliant is to include training information such as the equipment user manuals. Naturally, if you use a printed checklist, like our downloadable Inspection Checklist for safe generator operation, you may need help to include a user manual. There is another solution, however, to this predicament. Look at the right tools for the job section to follow – we’ve got the perfect solution for this situation.

Create Procedures That Make Sense

It may seem obvious, but you would be surprised how many managers create policies based on other policies, not reality. Have you ever driven into one of those parking lots that has a unique layout that led you in circles? Yeah, it’s like that sometimes when managers are too far detached from the positions they institute policies or procedures concerning.

The simple way around this situation is to have daily user feedback from the team members immersed in the process. These team members will provide invaluable feedback about inspection processes in their departments. Therefore, the best way to make policies that make sense is by including the team members involved.

Foster Equipment Responsibility

As we were just discussing the inclusion of team members, delegating specific responsibilities to specific roles within your organization is essential. By delegating specific responsibilities to individuals, such as delegation of any particular piece of equipment to a specific team member, you can ensure that two things are much more likely to happen:

- Being personally responsible for the equipment, the team member will ensure that the equipment is maintained according to manufacturer specifications.

- The team member will have ‘buy-in’ for inspection processes and provide valuable feedback regarding the equipment they are responsible for maintaining.

The Right Tools For The Job

Utilizing the correct tools is appropriate for any job or action. However, it would be best to have a robust solution to inspect equipment like generators. We’re not saying that the downloadable and printable checklist we have provided won’t suffice. On the contrary, you are limited to the extent that a piece of paper might afford. So, we need to look at a solution that can do more. Some of the features you need to consider are:

- Can the solution include a user manual?

- Does the solution let you include pictures, audio, or video?

- Can you customize the solution to meet your needs?

A paper checklist will only be capable of offering solutions for some of these items. Okay, you could make a new, customized checklist to print out. So, technically, if you took the time, you could satisfy the third scenario. However, it would be a nuisance if changes were readily required, especially if you disseminate the document to multiple people, branches, or facilities within your organization.

So, what is the appropriate solution for including the things we need to accomplish today’s inspections quickly and efficiently?

Let me introduce you to the 1st Reporting app. It’s a mobile application that utilizes secure cloud-based technology to deliver a customizable inspection and reporting platform. You’ll find everything you need, from a robust collection of pre-built templates to a custom form builder that lets you make exactly what you need.

Furthermore, this app has many more features, such as a powerful management dashboard, including a map view, to take advantage of the built-in GPS features. The app also works seamlessly with Microsoft Teams®, so you’ll never miss a notification of a team member completing a report.

Did we mention the app has customizable notifications and dynamic form building too? Those are things a printed form will never offer, so take advantage of this incredible technology and test-run the app for yourself – so you can see how a robust reporting platform can transform your business.