Understanding the requirements for fire watch is vital for team member safety performance involving hot work processes. Work actions that produce sparks, heat, or flame are all subject to fire watch protocol, so ensuring your team is up to the task is critical.

Unless you’re in the habit of watching buildings burn to the ground, we recommend a robust fire watch protocol. Subsequently, we don’t recommend ignoring fire prevention, so it’s best to ensure fire watch protocol compliance.

Fire watch is a protocol whereby an organization assigns an individual to manage fire detection within set parameters, such as within a specific area for a particular time.

Whether your organization follows NFPA (United States) or uses local regulations, most regions in the developed world have similar standards regarding the fire.

As a responsible manager or business owner, you must ensure that your organization is doing its due diligence to ensure that regulations are complied with and that life safety comes first.

According to the Insurance Information Institute, property loss from non-residential reported fires in the United States in 2021 was $3,564,000,000.00. I see many zeros and many reasons to make fire prevention a top priority.

In this guide, we’ll review what you need to know to properly manage your fire watch program and ensure that you keep up with the latest fire prevention safety. Let’s start with what your fire watch personnel are accountable for maintaining.

Requirements For Fire Watch Accountability

During the fire watch procedure, there are three levels of relevancy, officials, owners or managers, and contractors or workers. Each possesses a certain level of responsibility, or accountability, according to the NFPA.

Code Officials

Code officials are responsible for knowing and enforcing NFPA 51B.

Building Owners or Facility Managers

Owners and managers must ensure that a working procedure exists to:

a) document hot work hazards

b) advise contractors of site-specific hazards and rules

Of course, these procedures must adhere to local regulations.

Contractors and Workers

Contractors and workers must know the site conditions and rules and request information from supervisory or management personnel regarding site-specific hot work procedures.

Each person is responsible for fire prevention, from building owners to those on-site.

Assigned Fire Watch Personnel

The assigned fire watch personnel would be held accountable for responsibly attending to five critical things:

- Fire hazard identification

- Fire hazard monitoring

- Fire hazard prevention

- Fire hazard reporting

- Emergency alarm raising

Although you can certainly guess what is intended behind each of the five things a fire watch person is responsible for, it is easier to train new employees using a guide. Therefore, we’ve put together this guide, so feel free to bookmark it and share it with your team.

Let’s take a deeper look at the five concepts a fire watch person must adhere to while performing the task.

Fire Hazard Identification

The first responsibility of fire watch personnel is fire hazard identification. Fire hazard identification or FHI means that fire watch personnel must be constantly aware of their surroundings for any sign of fire. They must also be mindful of potential fire hazards, such as hot work processes.

Fire Hazard Monitoring

Fire hazard monitoring is the stage of fire watch when fire watch personnel actively look for signs of fire. Traditionally in cases of fire suppression system shutdown or failure, it merely means maintaining constant vigilance to actively seek out signs of potential fire within a predetermined area.

Fire Hazard Prevention

When a fire or smoldering occurs, the fire watch personnel actively attempt to extinguish the fire, depending upon severity and risk. Training must occur that is specific to your organizational needs. For example, a refueling station will not follow the same procedures as a tree-planting farm because the risks are dissimilar.

When the risk is acceptable, like a tiny smoldering ember, and the safety of the personnel is not in question, they must ascertain how best to combat the hazard. In many cases, it might be utilizing an appropriate fire suppressant, like a fire extinguisher.

Fire Hazard Reporting

Regardless of size, a fire hazard must find its way onto a report when someone encounters a fire hazard. Sometimes it’s as simple as noting on a hot work permit how the fire watch personnel extinguished some smoldering embers. However, the situation will affect the necessity for action, and your fire watch personnel must choose based on the severity of the risk.

Emergency Alarm Raising

Fire hazard emergency alarm raising is the stage of fire watch when fire watch personnel must sound an alarm to initiate emergency response. It might include calling emergency services or evacuating the building.

When To Engage In Fire Watch Protocol

According to the National Fire Protection Association (NFPA), a fire watch protocol is necessary whenever an existing fire alarm system impairment occurs. In layperson’s terms, when the fire alarm doesn’t work, you need to perform a fire watch.

However, if you work in construction or the trades, you’ll know many more situations where a fire watch implementation occurs.

Let’s look at the two primary fire watch protocol requirements categories.

Fire Monitoring System Failure

It would be best to have a fire watch protocol when a fire alarm or fire suppression system goes down. Never rely on a single system alone. If you have a fire alarm at work, you should include a simple fire watch protocol within your health and safety manual. We’ll look at what that might look like later.

Hot Work Process Engagement

Hot work is any process that creates a situation with potential fire. Typically we define these situations by obvious signs of fire, such as actions that produce heat, flame, or sparks.

A few common and quite typical hot work scenarios include:

- Grinding or cutting steel

- Welding

- Plumbing (soldering pipe fittings)

A few not-so-common hot work scenarios you might not realize:

- Circuit repair (soldering electrical connections)

- Simple hammering (in fine wood or paper dust environments or any flammable nearby)

- Staining wood (using oil-based stains)

The second list of uncommon scenarios might seem a bit odd to you – especially when you read that staining wood is a hot work scenario, but it’s true. Not all hot work involves obvious sparks and flame. Chemically induced fires are a real problem too.

The point is that your fire watch personnel must be ever vigilant. They must be on the lookout for fire and do so in a way tailored to your organization and operational situation. Every situation is different, so you must ensure that your fire watch personnel have the knowledge required for your organization’s hazards.

3 Basic Conditions To Apply Hot Work Protocol

Mix these three, and you absolutely must apply the hot work protocol.

- Oxygen is present. Oxygen is a requirement of fire, also known as oxidation.

- Fuel is present. Fuel could be anything that burns, from the rubber or foam bumpers on the sides of a loading dock to a wooden desk nearby or even a garbage can.

- A source of ignition is possible. Generally, we accept the assumption that the ignition source comes from the hot work performed, such as welding, although this may only be the case in some scenarios.

Fire Watch Regulations

In the United States, the NFPA regulations are the national standard. Similarly, the International Code Council (ICC) standards are accepted in the United States.

Other countries follow similar standards, although not all countries follow the same organizations. For example, Canada utilizes a government organization called the National Research Council of Canada (NRC) for code management.

Although the regulations for each country are very similar, there are some differences in code that we won’t get into today. However, let’s look at the fire watch protocol and see how they operate.

NFPA Fire Watch (USA)

NFPA 51B – Standard for Fire Prevention During Welding, Cutting, and Other Hot Work.

The NFPA has multiple standards for fire prevention. The essential takeaways include that any work completed that allows for the potential of a fire must have appropriate measures in place to prevent said fire.

The regulations include but are not limited to the inclusion of a 60-minute fire watch protocol for any hot work. This regulation stipulates that a sufficiently responsible person is responsible for maintaining fire watch initiatives for 60 minutes on-site following hot work.

You can find more information at the NFPA.

NRC Fire Watch (Canada)

Canadian fire watch regulations are not regulated by the NRC, as one might expect if aware of the American setup. However, Canadian laws are managed on the provincial level. For example, in Ontario, several different codes, including the Fire Code under the Fire Protection and Prevention Act of 1997, are relevant and apply, including the Ontario Building Code.

The code clearly states that buildings shall have working fire alarm systems and that when those systems fail, the organization must fix them immediately to preserve safety. However, the building code also stipulates that there must be a working fire alarm system at all times in buildings where people are present for work, occupancy, or other reasons.

Therefore, if a system is in a state of failure, human fire watch personnel must replace the broken fire alarm system for people to maintain their presence in the building safely. At least, the fire watch protocol must remain in effect as long as people are present in the building and the fire system is in failure mode.

Most provinces in Canada follow the national building, fire, and other relevant codes. Therefore, utilizing the national codes as resources is an excellent place to start.

Canadian Code Resources

Fire Watch Procedures

Best Practices

Identify alternatives to hot work. This action is the best way to prevent fire caused by hot work – to avoid the hot work in the first place.

If hot work is unavoidable, a fire watch attendant must:

- Recognize if a fire hazard exists.

- Evaluate the risk and determine potential fuel sources.

- Control and mitigate the threat with physical controls and preventive measures.

Of course, there’s more required deeper under the surface. Let’s look at what else we need to ensure takes place.

Health and Safety Manual Inclusion

As a responsible owner/manager, it is mandatory that you include a health and safety manual in your workplace. In the United States, the OSHA regulates this inclusion. However, the NFPA and ICC determine the specifics regarding code requirements, and the OSHA enforces the workplace requirements.

To include fire watch protocol within your H&S manual, you can merely state something similar to the NFPA requirements for hot work. We’ve outlined these requirements in this article regarding determining if a fire watch protocol is necessary.

To include your fire watch procedures, merely answer the following questions in your health and safety manual:

- When will the fire watch protocol apply?

- Who is affected by the fire watch protocol?

- Who is responsible for a) performing the fire watch and b) managing the fire watch process?

- How will fire watch processes occur, and how is the process documented?

- What are the fire watch stages for the personnel and the process managers?

- Any specific concerns or hazards within the workplace relating to fire watch processes and how they are to be addressed by team members.

Including these six preliminary items will get you well on your way to creating a robust fire watch protocol and including it in your health and safety manual.

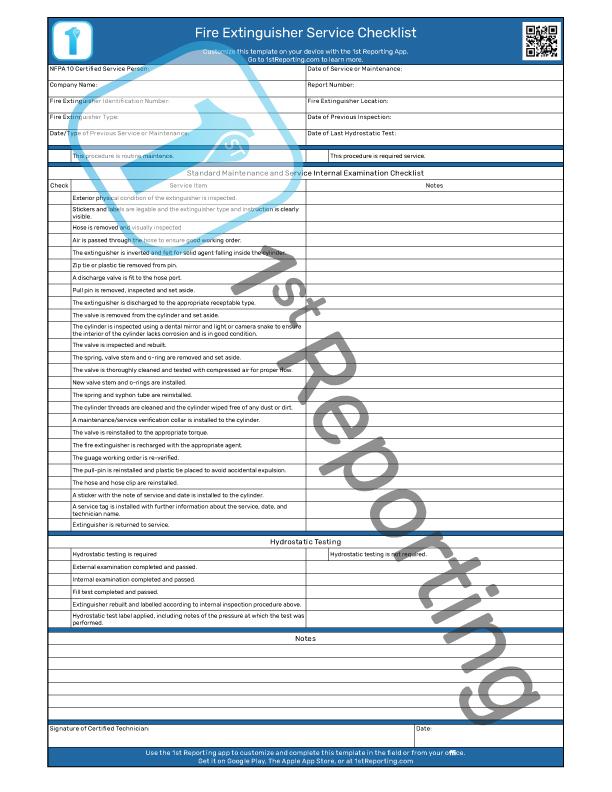

Documenting Fire Watch

Documenting fire watch protocol is critical, both from a legal responsibility standpoint and from a safety perspective. From the managerial perspective, completing a hot work permit or fire watch report ensures that:

a) The individuals involved follow the safe and approved fire watch or hot work appointed procedures.

b) Procedure documentation proves due diligence in following safety practices.

c) Documentation provides a record should an emergency arise related to the hot work incident.

Adopting a robust system for hot work and fire watch documentation is critical in today’s industries. And we have just the thing to aid your organization in completing, managing, and storing documents about hot work and fire watch procedures.

Here are two of our best options for successful hot work and fire watch documentation.

- Fire Watch or Hot Work Downloadable Templates.

- The 1st Reporting App.

Fire Watch or Hot Work Downloadable Templates.

In case you weren’t aware, we’ve got a robust library of pre-built PDF templates you can download and use in your organization. Everything from Fire Incident Reports to Hot Work Permits to Vehicle Daily Inspections and even Employee Injury Reports, we’ve covered you with a downloadable template.

Many companies and organizations still prefer to use old pen and paper regarding documentation. After all, a clipboard and piece of paper are cheap and easy to access. However, we don’t need to tell you the downside to paperwork. We all know paperwork is easy to lose, ink fades, bad handwriting makes it worse, and endless filing cabinets take up valuable floor space.

Enter the 21st century and technology, and we’ve got a better idea.

The 1st Reporting App.

After working for years to develop the systems to document, report, and manage incidents, we’ve perfected the art of incident documentation. We specifically built our app to ensure organizations have the digital tool to replace the archaic use of paper forms, checklists, audit templates, and incident reports.

Here are a few features that no printed checklist can ever offer:

Instant Form Retrieval

Our digital and secure cloud storage for our app means that your forms are easily accessible anytime and anywhere you have an internet connection.

Customization and Template Builder

The application includes a robust form builder to create the exact forms and checklists your organization needs. Specific form functions aren’t a problem for our builder, trusted by organizations and governments worldwide.

Automated and Dynamic Features

Never miss another report with a customizable notification system that lets you set up automated notifications to ensure the right manager receives a message upon specific form completion. The dynamic features let you do even more by linking reports, so retrieving and analyzing multiple report incidents is easy.

Mobile Application Access With Or Without Internet

Never again hear about a team member who went to a job site and forgot their paperwork. With our app installed, your team can access and complete any form in the app on their device. When they return to an internet connection area, the app will update the form they completed into the cloud system, so working without a connection doesn’t mean data loss.

Teams® Integration

No paper form will ever work with your computer except maybe as the subject of your scanner. With the 1st Reporting app’s Teams® integration, you can manage report notifications right inside the Teams® environment without opening our app.

There’s so much more you can do with the app that it seems a waste not to invite you to test out all the functionality yourself. So, try our app today and enjoy a free trial to witness the power of digital reporting and how it can make your work safer and more efficient.