A Mobile Crane Inspection Checklist is vital to using any mobile crane on any job site. Hoisting equipment often carries more than just weight – it carries significant risk. Mobile cranes offer some of the highest risks when moving things too heavy or too large to move on the ground traditionally. And we know that you take those risks seriously, just like we do.

The Mobile Crane Inspection Checklist is a safety audit form used by mobile crane operators to ensure they don’t forget to check any vital components before operating the equipment. Inspected daily or before use, mobile cranes possess the means to offer significant hazards by the very nature of the work they accomplish.

Hence, a Mobile Crane Inspection Checklist is vital for maintaining safe and operational hoisting equipment. So, we have created an industry-leading template you can download and use for your pre-use mobile crane safety inspections. First, let’s go over what we’ve included in this downloadable safety audit form for your mobile lifting equipment.

Included In The Daily Mobile Crane Inspection Checklist

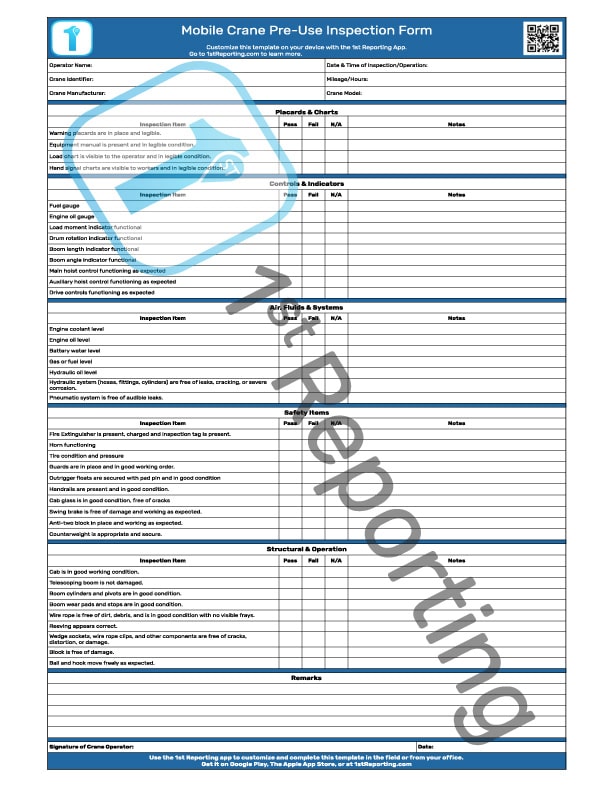

The Mobile Crane Inspection Checklist has seven sections that define the document’s body. These sections constitute both the necessity of the audit form itself and the five general sections of concern for the equipment. Here’s what you can expect:

- Administrative information

- Placards and charts

- Controls and indicators

- Air, fluids, and their associated systems

- Safety items

- Structural and operational items

- Overall inspection remarks

- Audit sign-off

Administrative Information

All safety audits need to identify themselves. This Mobile Crane Inspection Checklist is no different. At the beginning of the report, the administrative information section encompasses the traditional data such as the operator/inspector name, date and time of inspections, the crane identifier, make, and model of the equipment.

Placards And Charts

Placards, charts, and equipment documentation are critical to understanding equipment limitations. Not only is it a safety issue to maintain the proper placards and charts to identify equipment limitations, but it is also vital for worker-to-operator communications. Similarly, in many jurisdictions, capacity placards are a legal requirement. Therefore the operator of the equipment must ensure these placards and charts are present and in reasonable condition before commencing the use of the equipment.

Controls And Indicators

The controls and indicators present in a mobile crane are vital for operation safety. Given the crucial nature of these safety devices and instruments, a quick inspection before work commencement is a virtual necessity. This section of the Mobile Crane Inspection Checklist covers the standard gauges, indicators, and controls that one will need to inspect during a daily crane pre-use inspection.

Air, Fluids, And Their Associated Systems

Typical mobile cranes run using various complicated systems such as pneumatics or hydraulics coupled with a series of cable reels, motors, winches, wire rope, and similar mechanics. The systems that hold gases or liquids under pressure, such as the hydraulic systems, must face inspection before using the equipment. This section of the Mobile Crane Inspection Checklist includes vital points regarding these systems, such as inspection of hydraulic lines, fittings, and cylinders.

Safety Items

Mobile cranes carry a particular group of hazards where they operate. In fact, according to the Census of Fatal Occupational Injuries from the U.S. Bureau of Labor Statistics, between 2011 and 2017, there were 297 crane-related deaths. That’s an average of 42 per year over the seven years of the study period. Safety items couldn’t be more vital in our pre-use inspections.

The safety items section of the mobile crane inspection template includes fire extinguishers, horns, outriggers, rails, guards, and more safety-related items relative to the mobile crane equipment.

Structural And Operational Items

The structural and operational items of the Mobile Crane Inspection Checklist include items such as a visual inspection of the boom assembly, wire rope, reeving, block, ball, and hook, and even the cab condition.

All items on the inspection template include a pass, fail, or not applicable check field. Like other reports, each item also has a notes field on the extreme right. This field allows the inspector to note any items not clearly defined by the checklist. It might include notes for maintenance or even notes about specific things like a particular bulb type that requires replacement, for example.

Overall Inspection Remarks

Overall inspection notes and remarks are often vital to communicating items in disrepair or other such notations. The remarks at the end of the Mobile Crane Inspection Checklist could also be used as an overflow area where item notes above were not adequate to communicate the concern.

Audit Sign-Off

All safety inspections, audits, and similar require a sign-off at the end of the document. A sign-off shows any reader of the record that the operator attests to the validity and accuracy of the report. Subconsciously, it’s an inclusion to keep the operator honest and doing a good job. After all, they have to sign their name to the report.

How To Use The Mobile Crane Inspection Checklist

Using the Mobile Crane Inspection Checklist is relatively straightforward. However, we do have a few minor suggestions. Here’s the sequence of events that require attention:

- Download the mobile crane inspection template from this page. You can find more templates in our template library if you need other forms, audit templates, or similar documents.

- Print the template and make enough copies to account for the number of days and operators who will use the equipment. Remember, each operator must fill out their inspection checklist before using the equipment, even if an operator was using it before them, and fill out a list the same day. You should always ensure each operator completes a safety audit at the beginning of each shift using the equipment.

- Ensure the operator also has a copy or two of a form like the Fleet Repair Request Form if the mobile crane requires a repair noticed on the safety inspection. Similarly, suppose the mobile crane is transported to set up on a new site for the first time. In that case, you should have the operator or someone like the site foreman complete a Site Condition Report Template to ensure that the site conditions are suitable for portable crane equipment use.

- Have your equipment operator (trained and certified for the use of the equipment) complete a mobile crane safety inspection before using the equipment. As mentioned, this safety audit should occur before the operator puts the equipment into use. Even if the operator completed the same inspection the day before, it is advised that this inspection be completed on a shift-by-shift basis. In fact, it is mandated that the review occur, as mentioned in many areas.

- The operator should keep a copy of the Mobile Crane Inspection Checklist with them for the duration of their shift. They should hand in their audit checklist to the appropriate site manager at the end of their shift. The site manager should review the inspection and file it for safekeeping should retrieval in the future be required.

Frequently Asked Mobile Crane Inspection Questions – Answered!

We know you might have a few questions about your mobile crane inspections. We will do our best to answer any questions you may have, such as the following.

How Often Should A Crane Be Inspected And By Whom?

There are a few fundamental frequencies for mobile crane inspection.

- Before using the equipment, operators must complete a Mobile Crane Inspection Checklist like the one we are providing here for you today.

- Monthly. If regular use occurs, it’s wise to have equipment inspected monthly. Check with local authorities in your area to find out the specific inspection frequency required by law where you operate your business.

- Annually. Most equipment used in any workplace setting typically must be inspected by a professional (such as a certified mechanic) annually. Again, check with local authorities in your area for the mandated particulars in your state, province, or territory.

How Do You Carry Out A Safety Inspection On Mobile And Overhead Cranes?

Carrying out safety inspections on cranes should only be completed by those qualified to do so. With that said, any of your certified mobile crane operators should possess the knowledge required to do a basic pre-use safety inspection of the equipment. This knowledge is a part of the training for mobile crane certification, so by the nature of the operator’s training, they should have an in-depth understanding of the safety inspection required before daily use. Only a competent, trained individual should complete a mobile crane inspection.

What Are The Safety Devices In Mobile Cranes?

Mobile cranes have several built-in safety devices. However, some of these devices might be installed post-manufacture. Due to safety devices installed post-manufacture, testing them before using the equipment is advised.

Safety devices for mobile cranes include, but is not limited to:

- Warning indicators such as tilt indicator

- Outriggers to supply equipment support

- Counterweights to provide stability

- Swing brakes and other stopping devices to halt equipment movement

- Warning horns, beacons, sirens, or lights

- Guards, handrails, and additional pinch or crush, or physical hazard prevention measures

Best Practices For Mobile Crane And Equipment Inspection

There are so many different hazards on construction sites involving mobile cranes that one needs to pay extra attention. However, we don’t want to spend our whole day inspecting equipment when we need those hours operating it. A delicate balance between safety and efficiency ensues. So, how do we manage this balance without sacrificing operator or workplace safety?

Several best practices are superb at helping manage daily equipment inspections. As mentioned, we want to ensure that workers are safe and that the job is getting done (and getting done safely). However, the more in-depth a safety audit becomes, the longer it takes and the more it acts as a brake on project progress.

In order to compensate for safety inspections timeliness, it’s best to ensure that the elements we can control to make it more efficient are controlled. Factors such as the manner or means by which the operator records observational data.

For example, an operator trying to carry a clipboard with a paper report is fine – if it isn’t raining or windy, or they have nice clean hands. However, these conditions are seldom perfect in outdoor construction sites where the mobile crane finds a home.

To compensate for things like the wind blowing away paperwork, or an operator’s illegible writing, we have a simple solution that takes advantage of modern technology to make your job managing inspections a whole lot easier. Enter the mobile inspection app by 1st Reporting.

Using an app on a smart device like a smartphone or tablet solves multiple issues at once.

- No messy paperwork

- No illegible writing

- No lost paperwork

- No filing cabinet needed (no floor space requirement for filing)

The benefits to using a reporting application over the obvious ones you can glean from the above list are:

- Customizable notifications

- Customizable forms and templates

- Instant document sharing and retrieval

- Offline mode for data capture while out of range of an internet connection

- GPS incident management built-in

- Intelligent reports generated by submitted incidents and reports

Just think of the saved time you can get back using a semi-automated mobile form automation platform like 1st. Managing your team’s inspections has never been easier – if you’re willing to let the old printer and paper world behind. Join thousands of managers in getting back their time – try 1st Reporting today.