Are you struggling to get the most out of your suppliers? Do you feel like you could be getting more value for your money? If so, supplier performance management may be the solution you need.

Let’s take a deep dive into the world of Supplier Performance Management. We’ll talk about what it is, why it’s essential, and the three key metrics you can’t ignore. We’ll also involve a seven-step process to support the best practices for performing supplier performance management.

Finally, we’ll talk about tools you can use to enhance and automate your process to lower labor and speed up your performance analysis. Are you ready? Let’s jump in.

What Is Supplier Performance Management?

Supplier performance management is the process of monitoring supplier performance and taking corrective action when necessary. It’s essential for managers in any industry that relies on outside help to get the most value for their money.

By monitoring supplier performance, you can ensure that your suppliers meet your standards and deliver the quality and quantity of products or services you expect.

Why Is Supplier Performance Management Important?

In a fast-paced work environment, supplier performance management is critical. With so much at stake, managers need to take on the responsibility for the best of the company or organization.

Poor supplier performance can have a ripple effect throughout the entire business. It can cause delays, missed deadlines and decreased quality. In some cases, it can even lead to supplier bankruptcy and loss of revenue.

The good news is that you can avoid these problems with the proper supplier performance management process. By monitoring supplier performance closely and taking corrective action when necessary, you can ensure that your suppliers meet your standards and deliver quality products and services.

The Metrics You Can’t Ignore Measuring Supplier Performance

There are several key metrics that you should monitor as part of your supplier performance management process:

- Quality

- Delivery time

- Cost

These metrics are essential in assessing how well your supplier is performing. You can identify problems early and take corrective action before they cause severe damage to your business by monitoring them closely.

According to Jonathan Webb, a contributor to Forbes Business, there are three metrics groupings to convey the success of your supplier:

- Price

- Cost

- Quality

They define price as the basic price of the product or service supplied. It is a somewhat rudimentary way of looking at supply. However, it depends on how your operation reviews price analysis and how these relate to costs and the bottom line.

As Webb defines it, the cost is the metric that shows the total operational costs of a product or service. The view here is to adhere to a formula encompassing the ‘money going out’ to ascertain a supplier’s cost. It could associate subsidiary costs such as shipping, handling, administration, or other related costs to using the supplier’s products or services and gives a more accurate value to the expense analysis.

Quality-based metrics are the third group discussed. We agree that quality is indeed a high-priority indicator. Quality is often at the top of the metrics list when ascertaining the value of a supplier’s product or service.

Returning to our original three metrics, we believe delivery time must also be an analysis metric. Depending on the nature of the supplier and the logistics involved, delays in delivery time could cripple an operation.

Although some may view delivery time as a metric best included in the cost scenario, if you’re using price-based metrics for your analysis, you may want to include a separate delivery time metric. This inclusion will give you a better idea of the actual performance of the supplier.

Seven Steps To Ultimate Supplier Performance Management

- Define Business Goals And Needs

- Research Supplier Capabilities

- Establish Performance Indicators

- Create Supplier Scoring Protocol

- Review Parameters and Scoring Protocol

- Communicate Parameters To Suppliers And Set Internal Score Deliverables

- Review Supplier Performance

Define Business Goals And Needs

If you’re new to supplier performance management, or even if you’re not, learning to define your business goals and needs is critical to ascertaining the performance validity of a supplier.

To understand supplier deliverables, you need to understand the requirement you intend for the supplier to fulfill.

Start by defining your business goals and the needs for suppliers to fulfill and record these needs in a spreadsheet or somewhere that you can refer to or add to them as needed. Over time you may find other requirements to re-assess your supplier selection. Therefore, a record of your requirements will come in handy.

Research Supplier Capabilities

Determining your potential suppliers’ capabilities will help determine whether or not those suppliers will be worthy of your loyalty.

Research shows that suppliers that exhibit a bi-directional model of dependence on their clients offer a typically higher client-to-supplier loyalty than those that focus solely on one aspect, be it price, value, relationships, or something else.

The study would indicate by association that the most successful suppliers drive the most loyalty from their clients. These suppliers foster good communications (strong relationships), good quality, a reasonable price, and good or added value.

Establish Performance Indicators

To effectively manage supplier performance, it is essential to establish performance indicators. Performance indicators are quantifiable measures that help to track supplier performance over time. You can use them to identify improvement areas and help assess supplier value better.

Several factors, as mentioned earlier, can be used as performance indicators, depending on the needs of the business. Some common performance indicators are discussed above, and a few examples of each:

Quality metrics: such as defect rates, failure rates, return rates, customer satisfaction scores, etc.

Delivery time metrics: such as average lead time, on-time delivery, late delivery, missed delivery, etc.

Cost metrics: such as unit cost, cost overruns, procurement spend, supplier discounting, etc.

Establishing which indicators to use should be based on your organization’s operational processes and offerings. These will likely resonate with your needs established earlier.

Create Supplier Scoring Protocol

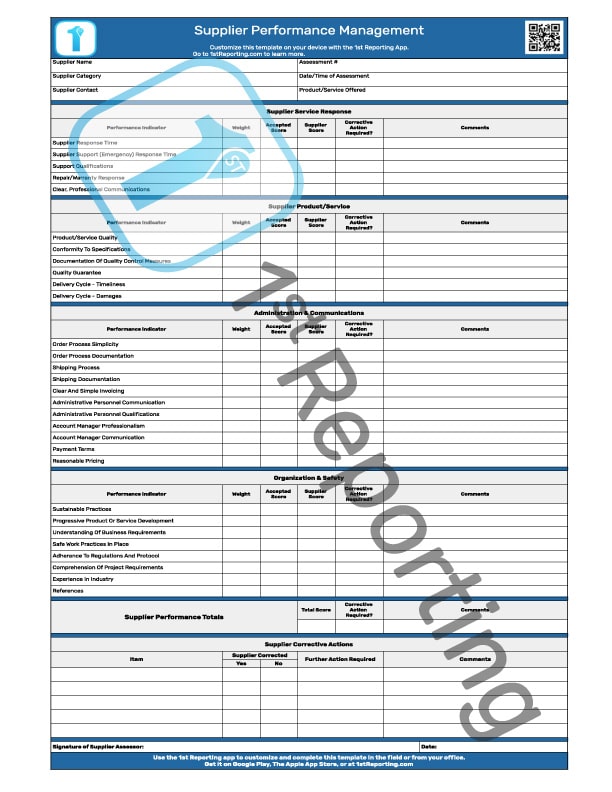

Once the performance indicators are selected, it is time to assemble a unified system to score the supplier’s performance. You can use tools like a mobile form automation app or other tools to aid you in scoring.

The scoring protocol needs to encompass several things. It ought to include when suppliers deliver products or complete services. You should include the frequency of your supplier performance reviews and other essential dates.

Creating a set of instructions for team members to complete the supplier performance scoring is also a vital aspect of the scoring protocol to consider.

Review Parameters and Scoring Protocol

Once you’ve got your scoring protocol set up, you can review the entire process before pushing it into live operations. The wise idea is to run a few dry trials to ensure that all variables appropriate to the supplier are captured during the scoring process.

Sometimes a review will catch an essential indicator but may have slipped your mind during the scoring supplier performance management system creation process.

Communicate Parameters To Suppliers And Set Internal Score Deliverables

The last stage after the review is to set the score metrics that your organization will deem internally acceptable. Then, once you’ve determined this final metric, it is time to communicate the concept to your suppliers.

Open communications to let your suppliers know the key metrics essential to the continued business partnership will be indispensable for the supplier and likely welcomed with open arms. That is, accepted by suppliers who hold a value to improvement. Those afraid of progress may not be so hospitable to your scoring process.

Review Supplier Performance

Once you’ve had a chance to implement your supplier performance management system, you need to start reviewing results. Analysis of your key indicators may reveal inadequacies that require remediation.

Depending on how your team decides to score your suppliers, scorecard analysis becomes more of a chore than an actionable tool for supplier management. You may want to consider a more robust solution, like an app that can handle the process and even automate parts of it for you.

The Advantages Of 1st Reporting And Mobile Form Automation

The 1st Reporting app is a mobile, cloud-based application. This application allows users to use either one of the many templates or checklists or create a customized form for reporting, auditing, or even process control.

With mobile form automation, your team can create customized supplier performance scorecards or audit templates that let your team efficiently complete the supplier performance review – from nearly any mobile device.

This application is invaluable to those who want to get away from relying on the old pen and paper. Not to mention lowering printing, paper, and ink costs.

When many supplier performance reviews are in the system, reviewing them all for trends can be overwhelming. Indeed the process can be more than a little time-consuming. But with 1st Reporting, you have automation and computational power.

Running reports in 1st is easy. The app can reveal trends in your reports that would otherwise take hours or even days to comb through reports to ascertain.

It isn’t just trend analysis that’s easier, in any case. Customizable notifications and instant document-sharing capabilities are also at the top of the list of features. You won’t know how you ever lived without it.

If you’re ready to take your supplier performance management and all other reporting to the next level, don’t hesitate to download 1st Reporting now – available on Google Play and The Apple App Store.