Updated December 6, 2024.

Think scaffolding is just metal and wood? Think again. It’s the backbone of any construction site—but only if it’s safe. In this guide, you’ll become a master of scaffolding safety tagging.

Following proper scaffolding inspection tag and inspection procedures coinciding with adequate team member training ensures safety on the job site. But do you fully understand how to properly tag scaffolding and inspect it for safe use?

Scaffolding tagging is a safety procedure used on construction sites to label scaffolding structures and communicate their safety status to workers and site visitors.

These tags provide crucial information about the scaffolding’s condition, usage restrictions, and any hazards associated with it.

Using a color-coded or standardized tag system, scaffolding tagging helps ensure that workers only use scaffolds that have been adequately inspected, are secure, and are safe to use.

There are several regulations that your organization must follow regarding erecting scaffolding. Depending on what country or even region, the rules may be slightly different from one another, so always check with your local officials.

We’ll cover a few basic concepts here about the proper scaffolding tagging process and shed some light on the regulations in the United States under the OSHA. Canada, Australia, and Britain follow similar guidelines.

Scaffolding Tagging – Where To Begin

Scaffold Identification

Start by identifying what you’re working with. Generally, there’s supported and suspended scaffold, but some may consider lift equipment like scissor lifts to be in the same category. For the purpose of clarity, this article focuses on the tagging requirements for supported scaffold systems. However, take a look at the table below to clarify the type of equipment you’re using first.

| Supported Scaffold | Suspended Scaffold | Lift Equipment | |

|---|---|---|---|

| General Information | – most common, typical rectangular tube and plank construction, fixed position | – typically window cleaning and maintenance for high-rise facilities, moveable | – scissor lifts, aerial boom and bucket lifts, mobile |

| Requirements | – working at heights training and equipment required – daily pre-use inspections needed | – working at heights training and equipment required – daily pre-use inspections needed | – working at heights training and equipment required – daily pre-use inspections needed |

| What it looks like |

|

|

|

Scaffold Basics – What To Know Before Scaffolding Tags Are Managed

Who Can Apply A Scaffolding Tag?

According to OSHA, only a trained and competent person may manage (or inspect) scaffolding. If you have questions about particular regulations, you can access the scaffold e-tool here. Now, let’s get into scaffold tag basics.

Scaffolding Tags Requirements Explained

- Training – Preliminary training is required to ensure a competent person receives training in the erection of scaffolding systems. The person who will inspect the scaffolding must be deemed confidently trained to do the inspection appropriately.

- Inspection – A competently trained person shall inspect the scaffolding after assembly for use. Inspections must occur before use and at the beginning of each day. If multiple shifts are working on it, your team should inspect the scaffolding at the beginning of each shift.

- Tagging – Scaffolding must be tagged following each inspection. The tags communicate vital information to keep workers safe and aware.

- Communication – Its regulated practice to inspect and tag scaffolding systems. It is also wise to maintain a scaffolding communication board or book on a job site where workers can find information about their scaffolding before starting work.

Scaffolding Tags and Color Coding

The basic concept of scaffold tag colors is similar to what you’d expect from a traffic light.

- Green Tags: Indicate that the scaffold has been inspected and is safe for use.

- Yellow Tags: Show that the scaffold is restricted in use. For example, it may only be partially assembled or have weight or access limitations.

- Red Tags: Warn that the scaffold is unsafe and should not be used. These are typically placed on scaffolding under construction, being dismantled, or in need of repair.

Although on scaffold tags, there is more information conveyed than just the go, caution, and stop that the colors can communicate.

Green

There are several different styles of scaffolding tags. Typically, scaffolding approved and rated scaffolding for a particular load will get tagged with a scaffold tag that is green primarily or easily communicated as a safe pass from the inspection. This initial communication lets workers know at a glance that the scaffolding is both inspected, and safe for use.

Proper green scaffold tags should include the date and time of the previous inspection and show the scaffold rating. A green tag means the scaffolding was erected as manufacturers intended and have no modifications.

Yellow

It is generally accepted that yellow tags get used when scaffolding is safe for use but modified to suit the particular job site’s requirements. It may therefore pose a non-standard hazard. The yellow tag warns team members that there may be a variation in the construction of the scaffold that is out of the normal sphere and extra caution needs to be committed to the task.

Red

As is the case with what you would expect, red means stop. A red tag on a scaffold is generally accepted to communicate that the scaffold is unsafe for use. Perhaps a repair or something else is required, but your team should tag it with a red tag if the scaffold does not meet inspection requirements.

Struggling with keeping track of scaffold inspections? Our 1st Reporting app streamlines the process, making safety management a breeze. Try it now!

Essential Elements Every Scaffold Tag Must Include

As mentioned, there are several different designs of scaffold tags. No regulation states that the design must be one way or another. However, there are a few things that you must include on a scaffold tag. We’ll detail each necessary tag inclusion below.

- Scaffold Identification Tag Number – All scaffold tags must have a legible identification number on the tag for identifying tracking the scaffold and inspection. (source)

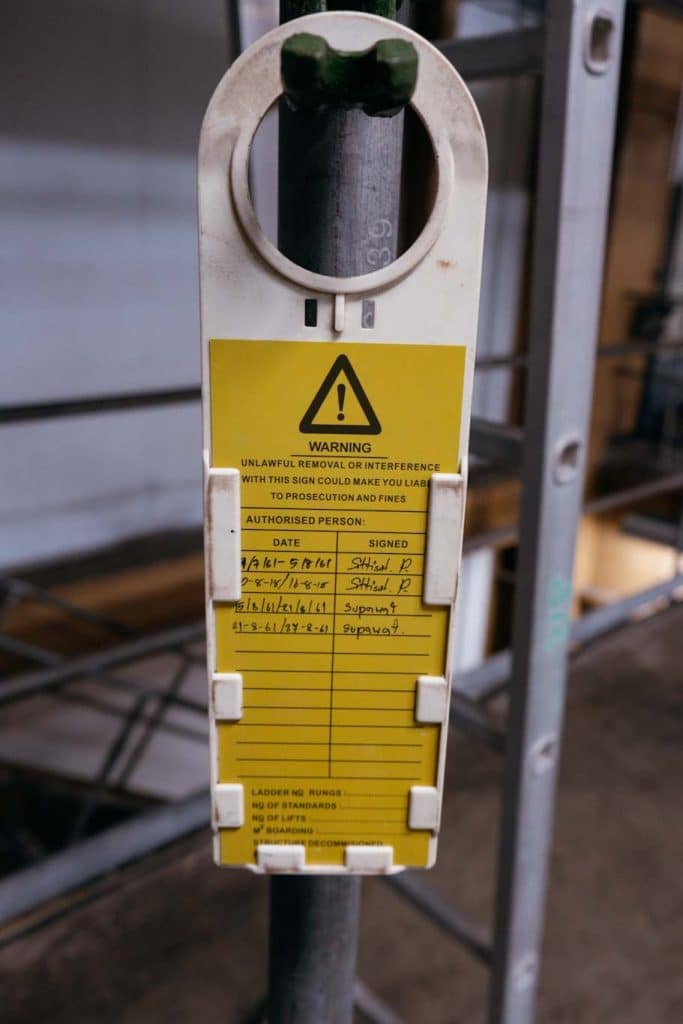

- Tag Colors – the tag must be solid green, yellow, or red in color with black lettering. As you may have noticed in the image above for the green and red tags that not all manufactured tags follow the specific regulations but maintain the color code to some degree nonetheless.

- Scaffold Important Dates – The date on which the platform was erected and also the date your inspector inspected it should be noted on the scaffold tag.

- Inspectors’ Names – Each time the scaffold is inspected, the inspector should print and sign their name (with the inspection date) on the scaffold tag. This practice records the specific scaffolds inspections for easy retrieval when necessary.

- Installer/Maintainer/Disassembler Information – Typically, on the back of the scaffold tag, you will find a place to commit information regarding the company or department that is responsible for three things:

- Correct scaffold installation

- Proper scaffold maintenance

- Safe scaffold disassembly

The exact tagging requirements may be slightly different, depending on where you live. With this fact in mind, we suggest you read on to the scaffold standards section next to find the country and governing body that corresponds to your job site location.

What Are The Scaffold Standards

The basic scaffolding standards are the same from country to country, with a few minor exceptions. We’ve included links below to four of the most popular countries to search for this information. However, there are a few things that all country’s standards and scaffold regulations recognize.

- Accepted design – The manufacturers of scaffolding offer specifications to the maximum type and height of design that companies may use the scaffolding for in a safe manner. As long as the scaffolding design is accepted within the manufacturer’s parameters, it should meet this requirement. If the plan is non-standard, it should be professionally engineered.

- Secure footing – The base of the scaffolding must be firm and secure.

- Possible guarding – There are some variations to the specifics for guarding, but the idea is that wherever possible, you should install guard rails and other hazard prevention devices.

- Plumb and level – All legs should be plumb and all platforms level.

- Rated decking – All platform decks must be of quality lumber of the proper thickness, width, and length. The lumber decks must conform to quality standards and be free from rot and weaknesses.

- Locks and ties – All locking devices, ties, and braces are firmly secured and locked in place.

- Inspection documentation – You must inspect scaffolding after being erected. It must also face inspection before the beginning of each work shift or day. These inspections should be logged, and the log maintained in case of an accident and required document retrieval. We recommend a mobile reporting app as your primary solution for this (and all your other reporting/safety audit needs, of course).

For more information about specifics, see each country’s regulations and be sure to consult with your local officials for local specifications such as permits.

USA

OSHA has documented the required USA Scaffold Standards that your job site must comply with in the construction industry. These standards are valid in the United States of America.

Canada

In Canada, the Canadian Centre for Occupational Health and Safety (CCOHS) has the government-documented Canadian scaffold requirements for scaffolding that can be found here and are valid for Canadian provinces and territories.

Australia

Here, you can find Australian scaffolding regulations on the Standards Australia – Standards Catalogue website. The regulations detail all of the scaffolding requirements for the country.

United Kingdom

The United Kingdom again has similar laws to other countries mentioned. You can find all of the specific scaffolding regulations for the UK at the Health and Safety Executive website here.

Tips To Effective Scaffold Inspection And Tagging Procedures

There are several things that your organization can do to mitigate some of the tedious issues that arise with inspecting scaffolding and maintaining those inspection records. Here is a list of tips we recommend you follow to increase your organization’s inspection and reporting processes, save time and money, and make your team members’ jobs a little easier (for a greater chance of lowering operational mistakes).

- Always perform a Job Hazard Analysis before moving scaffolding on site. This procedure tends to catch job site conditions that may make the site inadequate for scaffolding use. Finding this out before moving the scaffold to the site can save you time and money.

- Standardize your inspection templates. We’ve created an extensive library of downloadable templates that you can use to streamline and standardize your construction site inspection processes.

- Utilize checklists for complicated processes, procedures, or inspections. Training team members to use a checklist for inspections or other complex operations ensures that they won’t forget specifics. This practice is one-way businesses are ensuring quality results from their team.

- Use a cloud-based reporting solution. Using a reporting/digital template solution like the 1st Reporting app (available on Google Play and The Apple App Store) for all of your forms, checklists, inspections, audits, and other documented processes allows your company to do several things at once over those that utilize print and paper:

- Lower printing, paper, and ink costs

- And lower overall overhead by not requiring filing cabinets to take up valuable floor space

- Lower reaction time to inspection and reporting results

- Increase efficiency by standardizing documentation

- Automate processes with customizable notifications

- Customize templates to suit your company brand (without re-printing templates)

These are just a few benefits you’ll find when you test a mobile form automation solution like 1st Reporting to see how it will benefit your organization and make managing incidents, inspections, and processes that much easier.

Safety is non-negotiable. Become a scaffolding safety pro today by following these guidelines and using our 1st Reporting app for seamless inspection management.