Effective management of the job safety analysis process is vital to its success. But what are the best ways to manage a process intended to seek out and identify hazards that could slow or even stop work? The answer is simple: A properly coordinated and managed approach to the job safety analysis will keep staff safe and effective.

Knowing the right way of managing a job safety analysis process might elude you in a situation where politics or other factors weigh heavily on your decisions. Nevertheless, we’ve compiled some handy tips to help you manage and overcome the issues you may face with the job safety analysis (also known as the job hazard analysis or even the activity hazard analysis).

Stay with me. Today, you’ll learn practical and actionable tips to improve your operations, create a safer work environment, and make your job a lot easier (seriously). Let’s dive in.

Benefits Of An Effective Job Safety Analysis Protocol

Before we discuss the tips, let’s understand why you should be motivated to read through them and utilize them within your organization.

- Improved Safety. An effective JSA helps your organization eliminate potential hazards before someone gets hurt.

- Improved Morale. A workforce that feels safe works harder and is more loyal to its management team.

- Improved Company Culture. A workforce that feels that their safety and well-being are essential to their employer will be happier and more willing to participate in a team-oriented workplace culture.

- Reduced Risk. When you work hard to eliminate hazards, you also eliminate company and management risk exposure.

- Reduced Loss Time Events. When operations have to grind to a halt due to an accident, it’s more than just a person who may be injured. The entire business suffers when these situations occur due to the side effect of loss of business due to operation stoppage.

- Reduced Insurance Rates. The rates may not be reduced, but preventing accidents prevents insurance from climbing due to at-work accidents. Technically, the rates are reduced from those a business would face after an at-work accident involving injury or even death.

Tips For Managing Effective Job Safety Analysis Processes

We could all use some tips for managing effective job safety analysis procedures. Some of the following tips may seem simple, but read through each section to see that they are often more complex than initially considered. Also, making such assumptions has ramifications, so ensure you check each section below before you make that mistake.

- Communicate the intentions of the safety audit.

- Use a job safety analysis pdf (JSA template or form).

- Map out the walk-through.

- Make pre-notes on known processes.

- Always document your JSA/JHA.

- Map out extensive processes.

- Ensure backup inspectors are available.

- Understand your obligations.

- Use a digital reporting system.

Communicate The Intentions Of The Safety Audit

There are two schools of thought for managing safety inspections, such as a job safety analysis. The first school of thought believes that one should perform surprise inspections. The idealogy behind this is motivated by a catch-the-thief mentality. Managers who embrace this process often separate themselves from the workforce, alienating them and causing a divide between management and staff.

The other school of thought on performing JSA is communicating the intentions of the safety audit to anyone involved at the job site. This form of action does two things. First, it includes the workforce in the process, which increases team morale. Second, staff will often prepare for the inspection, knowing its arrival.

It might be considered counterproductive; however, if staff is preparing for a safety inspection, is it not better than if they were not preparing? With regularly scheduling these JSA inspections, staff will eventually, if not inevitably, comply with the inspection requirements due to a lack of desire to repeat having to prepare for said inspection.

Use A Job Safety Analysis PDF (JSA Template Or Form)

“Concern for man and his fate must always form the chief interest of all technical endeavors.”

Albert Einstein

Given the elements of a job safety analysis, attempting to ‘wing it’ on the job site is not advisable. If you or your staff perform the inspection, a pre-determined form or checklist will aid in a consistent reporting experience.

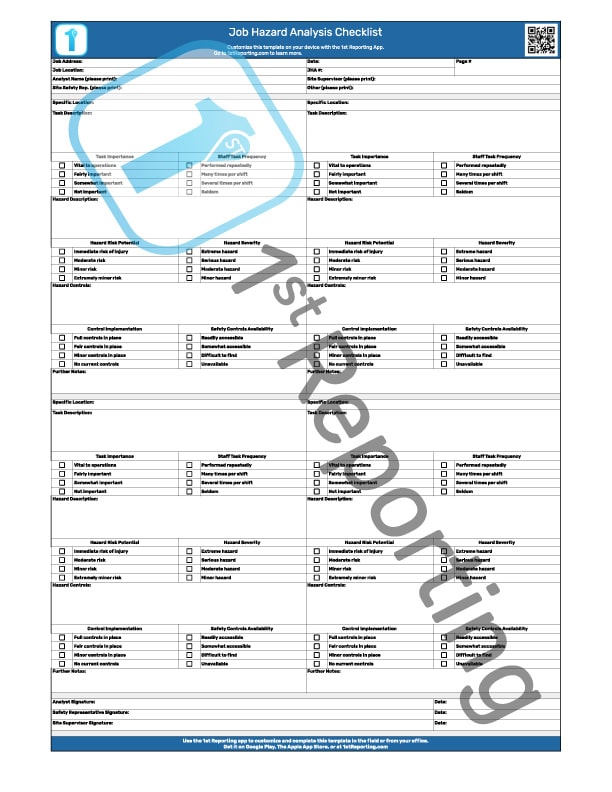

We’ve created a PDF version of the Job Hazard Analysis Checklist (or Job Safety Analysis) that you can download. The JHA Checklist is here.

Map Out The Walk-through

The organization is vital to many processes within many industries. The JSA process is by no means an exception to the rule. Suppose you or your staff are performing the JSA; complete (or have them complete) a walk-through program first. Identifying the stations and processes at the job site makes it easier to identify misaligned procedures or faults within the safety concept for all processes.

Hazards become more apparent when we have done some basic familiarization with the processes. However, having a plan of action also helps you or your staff analyze the process further and maybe even find ways of improving a particular stage. It is one of the many reasons why mapping out your walk-through path is essential to visualizing and understanding the processes involved.

Make Pre-notes On Known Processes

A job safety analysis is a process whereby an analyst reviews the various stages and steps of a process within a particular role or task and analyzes the hazards and safety precautions involved with the process.

When your analyst inspects a process for hazards and subsequent safety, they must understand the process to comprehend all its dangers adequately. It is where a pre-note system for job safety analysis is critical. An analyst could read some notes, familiarizing themselves with a process before engaging the JSA on the job site.

This pre-research allows the analyst to better define the roles and responsibilities of staff involved with each task analyzed and to understand better how and where potential hazards may present themselves.

Always Document Your JSA/JHA

There is an old saying among business owners: “He (or She) with the best paperwork wins.” This statement is true in life, business, court, health, and safety. That’s why it is vital that your organization not only performs regular job safety analysis audits but that they are well-documented and well-organized.

If you want the best solution for adequately documenting and storing your JSA inspection documents, keep reading, we reveal the best solution later in the article.

Map Out Extensive Processes

As a manager, you know that when others complain something is too complicated for them, it often falls on you to comprehend and complete or manage the completion of the task. When it comes to comprehensive JSA inspections of complicated processes, it can be overwhelming for some staff to comprehend.

Breaking down complex processes into smaller and simpler processes is the only way to allow anyone involved to comprehend the breakdown of the facility or equipment processes. Mapping out those complex processes may allow for more straightforward JSA completion since not too many extraneous steps are included when not required or omitted.

Ensure Backup Inspectors Are Available

One issue that happens occasionally in construction and other job sites where a JSA is vital to clearing a worksite for safe work continuance is the unavailability of an appropriately appointed job safety analyst.

Often, the analyst is a member of the health and safety team. However, depending on the size of your organization, you may not have a backup analyst to cover when your primary analyst is unavailable.

These sorts of slow-downs for small businesses can be very damaging. They can cause owners to complete their own JSA inspections and often miss vital aspects of their processes.

Understand Your Obligations

Quick Reference:

Whether your organization operates in the United States of America and the presiding body is the OSHA or in Canada, where the presiding body is the CCOHS, understanding your obligations as a manager is crucial to managing staff safety in the first place.

Many mid-level management teams believe that the responsibility for safety falls on the top people within the organization. This is not true.

Although owners and top managers do indeed bear a lot of responsibility for a company’s safety, every manager or supervisor who presides over anyone else is equally responsible for ensuring the safety of those who work ‘under’ them.

If you’re a manager, you are responsible for the safety of those you manage.

Managing your workplace JSA inspections and ensuring the safety of all staff is and should be a primary goal of all managers at all times, not only for their responsibilities but also to help prevent accidents or injuries.

Use A Digital Reporting System For Your JSA Audits

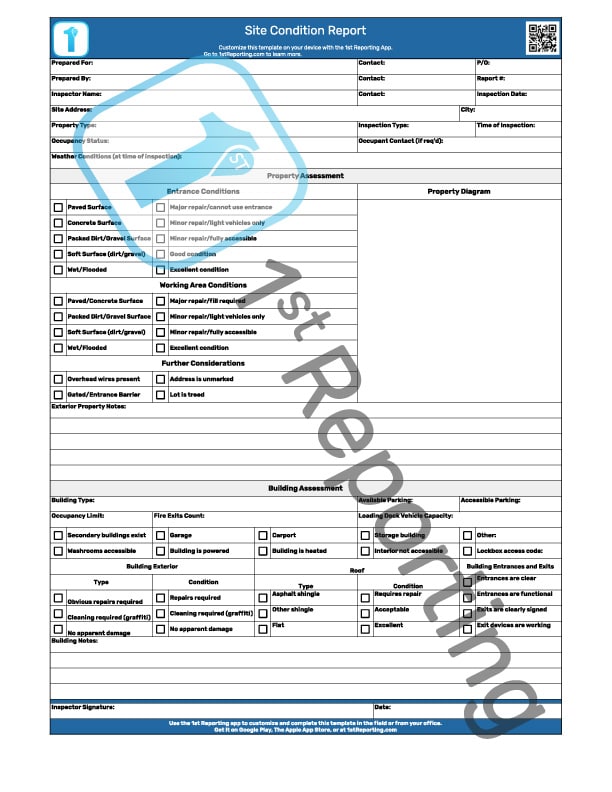

One of the best ways to manage an efficient and effective Job Safety Analysis is by utilizing what current technology offers. Don’t get us wrong; we created the downloadable Job Hazard Analysis checklist to help you grasp a uniform JSA process, but the best solution is not to have to print anything at all. Here’s how it works:

Like 1st Reporting, a digital reporting system lets your inspectors and analysts complete a JSA or other audit on the screen of their smartphone, tablet, laptop, or other devices.

A few key benefits include:

- No wasted paper

- No use of expensive ink

- No need for filing cabinets

- No physical handling of the report

Better still is the ability to customize any of the templates pre-built into the user library. Also, the customizable notifications allow you to set up a notification to let the right person know at the right time that an inspection has been completed.

If you’ve heard the expression, ‘A picture speaks a thousand words.’ then you know the value of taking a picture or video when a hazard presents itself. Sometimes, a picture can say more than a whole page of reporting can.

A digital reporting solution allows your users to upload pictures, audio, or video files right from their smartphones or other devices. With this kind of reporting ability, the days of printed paper will soon go the way of the dinosaur. So, isn’t it best for your company to move forward and try out the future of incident reporting today? Try the 1st Reporting app on computers, laptops, Android, or iOS devices today.