Common electrical hazards are invisible, yet some of the most dangerous hazards in the workplace. Although only 3% of workplace fatalities in 2019 were caused by electricity, the hazard holds a title of a whopping 8% of electrical injuries resulting in death.

Keeping your staff safe from this unseen menace is crucial to a safe workplace environment. Due to the need for increased electrical safety awareness, we’ve compiled this list of the familiar and often overlooked electrical hazards in the workplace.

Managing An Electrically Safe Workplace – What Is Electrical Safety And Why Is It Important?

As you know, electricity powers our world, or at least most of it. We use it at work for everything from powering our computers and facsimile machines to powering our lighting and often equipment.

Electrical safety is the practice of recognizing electrical hazards, mitigating and eliminating those hazards, and training staff on electrical hazard awareness. Electrical safety is a multi-faceted process that must involve:

- Identification of risk

- Calculation of risk potential

- Mitigation of risk

- Prevention of hazards

- Elimination of hazards

- Training

The importance of electrical safety is obvious: Electricity is an invisible hazard you cannot see, taste, or touch. As such, electricity poses an escalated risk above other, more visually noticeable hazards and thus requires extra due diligence for managing the risk to staff health and safety. The goal of every workplace must be to keep staff safe from hazards both seen (such as vehicle accidents, for example) and unseen, such as electrical hazards.

Electricity can kill a human being with as little as 0.1 to 0.2 amps. (source)

11 Most Common Electrical Hazards In The Workplace

We’ve identified 11 typical workplace electrical hazards and causes that are listed and explained below. Many of these hazards are common, and some are overlooked, so ensure you read them all to the end, so your workplace doesn’t miss one of these potential hazard scenarios.

- Contact With Buried Power Lines

- Damaged Electrical Cords And Cables

- Inadequate Circuit Grounding

- Inadequate Personal Protective Equipment

- Inadequate Tool Condition Or Use

- Inadequate Training

- Mislabelled Panels And Circuits (Secondary Sources Of Voltage)

- Overhead Power Lines

- Overloading Circuits

- Undersized Wiring And Cables

- Wet Conditions

Following are each of the scenarios explained. The list is not in order of commonality but merely arranged alphabetically, so don’t assume any of these hazard situations are any more common than another.

Contact With Buried Power Lines

A common situation in many renovation projects has to do with digging. Often there are power lines and other dangers under the surface that are unseen. If staff is tasked with creating a trench, installing bollards, or even fences or signposts, digging without proper investigation may be a severe hazard.

Request a Locate – Your Best Defense Against Buried Electrical Hazards

- In the United States, to find out if there is buried electrical, you can access the Call 811 resource to find out if there is a hazard underground at the site.

- In Canada, you can contact Dig Safe Canada to request a locate.

Damaged Electrical Cords And Cables

The threat of shock from electrical cords and cables is genuine and prevalent. In fact, it’s one of OSHA’s top electrical violations – damaged cords in the workplace. The control of hazardous energy (including Lock Out and Tag Out) is number 6 on the OSHA’s top 10 most frequently cited standards. (source)

Damaged cords in the workplace are often found on extension cords and power tools. Industries that utilize a workforce that utilizes a lot of power equipment, such as construction, have the greatest chance of these hazards. However, it should not be overlooked in other industries.

Inadequate Circuit Grounding

Similar to the damaged cords scenario is the root cause of many electrical faults causing shock – inadequate or broken grounding on a circuit.

The most common place to find this hazardous situation is with three-prong extension cords. Workforces that utilize power tools are often found facing this hazard. Service technicians often remove the ground on a cord to accommodate a power supply utilizing older 2-prong receptacles.

Mitigating Circuit Grounding And Electrical Cord Problems

- Ensure all cords are properly grounded.

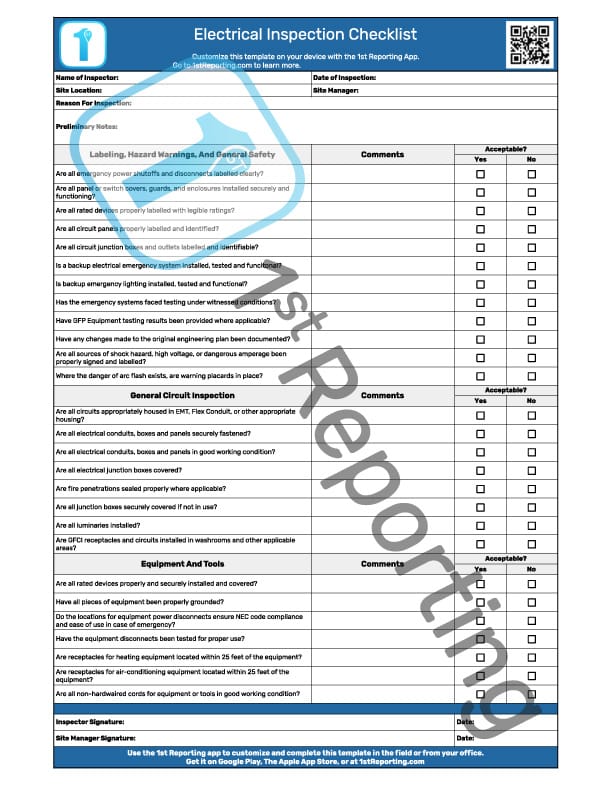

- Have your facility electrically inspected to ensure all circuit receptacles are safe and properly grounded.

- Institute power tool and cord inspections on a scheduled regular basis.

- Only use electrical cords in top condition and discontinue use of those not up to perfect working standards.

Inadequate Personal Protective Equipment

Electricity is a frightening hazard that many take for granted. Businesses that attempt in-house electrical repairs are often either ignorant or utterly unaware of some of the more dangerous aspects of electricity.

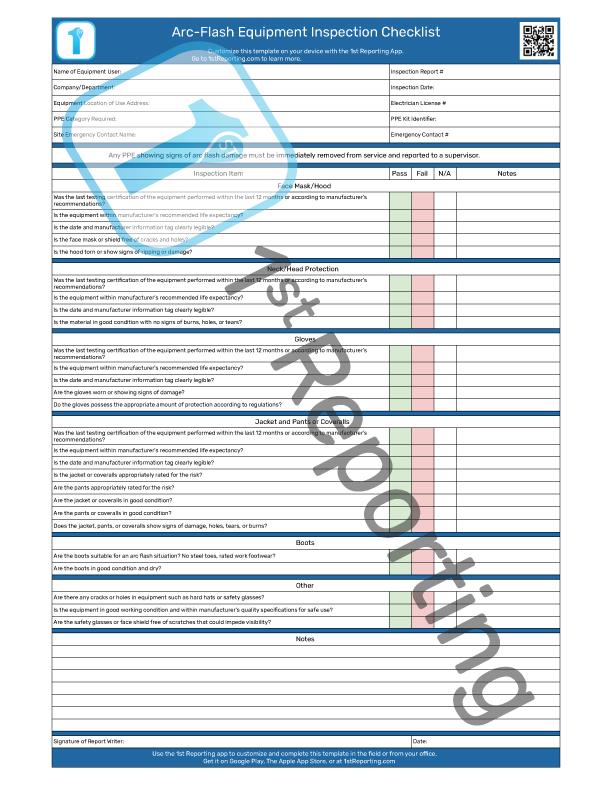

Take arc flash as an example. When a circuit is overloaded with electricity, and the voltage level increases enough that the electricity can ‘jump’ out of the circuit, the result is often a violent arc flash.

An arc flash is mini lightning escaping an electrical circuit. It can happen from dust, tools (we’ll get to that next), moisture, corrosion, part failure, or even faulty installation. (source)

How To Prevent Arc Flash

- Only have appropriately trained personnel (licensed electricians) work on electrical circuits.

- Provide adequate arc flash protective personal protective equipment (PPE).

- Maintain good electrical standards up to or better than the legislated electrical code in your area.

- Never work on live equipment.

Inadequate Tool Condition Or Use

If you’ve ever looked into a tradesperson’s toolbox, you’ll often see hand tools that are used and abused. The same is true for many service technicians, electricians, and other tradespeople.

Tools such as grinders and other power equipment are often abused in heavy labor situations, especially on construction sites where conditions are rough at the best of times.

Again, utilizing a tool inspection program (just like inspecting the cords on equipment) is essential to maintaining safe working conditions for staff.

Try using an incentive program to have your workforce take the best care of their provided tools.

Ensure that all electrical testers and tools are in top condition when inspecting tools. Vitally essential is the process of inspecting hand tools such as electrically insulated screwdrivers and other electricians’ hand tools. The insulating qualities may become forfeit with improper use, giving rise to a near miss or potential employee injury scenario.

Inadequate Training

Sometimes companies, especially smaller ones with a family-oriented culture, will have staff who strive to handle situations and mitigate issues on the company’s behalf. Often this sort of staff loyalty can lead to dangerous situations where staff who are inadequately trained in electrical repair or troubleshooting volunteer to attempt a repair.

These situations often lead to employee injury caused by electric shock, a short circuit, or even a fire.

Training staff is vital, if not critical, to keep the wrong hands out of the electrical panel. Ensure your staff is trained on what to do when an electrical hazard is observed and who to call to fix the issue safely. Staff needs to know where power shutoffs are, and all staff should be trained in emergency power shutdown procedures.

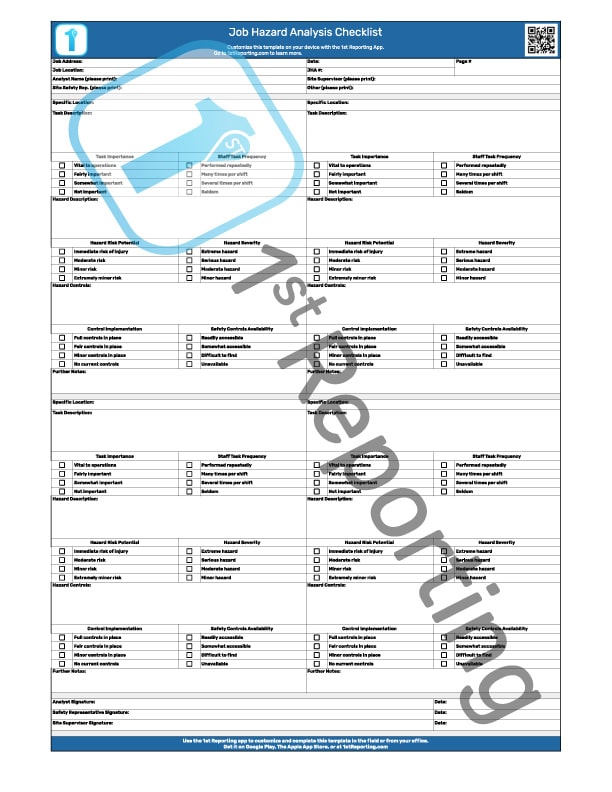

If you’re utilizing a digital reporting solution, ensure that your staff is equally trained on the processes and procedures for utilizing a mobile application or similar reporting system. These systems can help to automate your reporting processes to amplify productivity. In the long run, automated reporting and auditing processes save on training because you can merely create a custom procedural checklist for your staff to follow in the case of electrical emergency incidents.

Training staff beginning with digital solutions for your site electrical safety inspection documentation is an intelligent way of adding administrative controls to your scenario. According to some, utilizing administrative control is when you change how people work to better their safety. That concept is why using a mobile digital solution for emergency procedural checklists is not only cost-effective; it’s a preventive measure to ensure emergency protocol is followed. And with the custom instant notifications, the right people can get notified at the moment.

Beginning staff training in automated digital solutions is easy when you have excellent support and an easy-to-use interface. It’s just another way that technology is helping to improve electrical safety programs within businesses today.

Mislabelled Panels And Circuits (Secondary Sources Of Voltage)

There are countless situations where a circuit panel might carry multiple voltages. There are also numerous situations where equipment might have separate power sources converging within the same panel or controller box.

A mislabelled panel that houses multiple voltage sources could remain energized if one of the sources has been powered off. However, staff might assume that the panel or circuit is not energized, having locked out what they thought was the power source.

Another typical instance of mislabelling is the circuit panels of the building itself, where the business operates. Many businesses operate under the ‘if it’s not broke, ignore it’ policy. They tend to a power panel with multiple unmarked breakers when a power issue occurs.

In the circumstance of an unmarked panel, the seconds it takes for a person to stand there and determine which they should shut off in an emergency might be the difference between life and death.

The moral is to maintain good records; that doesn’t just go for what’s on your computer, desk, or filing system. It also means maintaining good labeling practices and training for staff regarding emergency power shutdown procedures.

Even an office can spill mop water on a power cord, electrocuting a person. Electricity and knowing which breaker to turn off in an emergency is intelligent no matter what type of business.

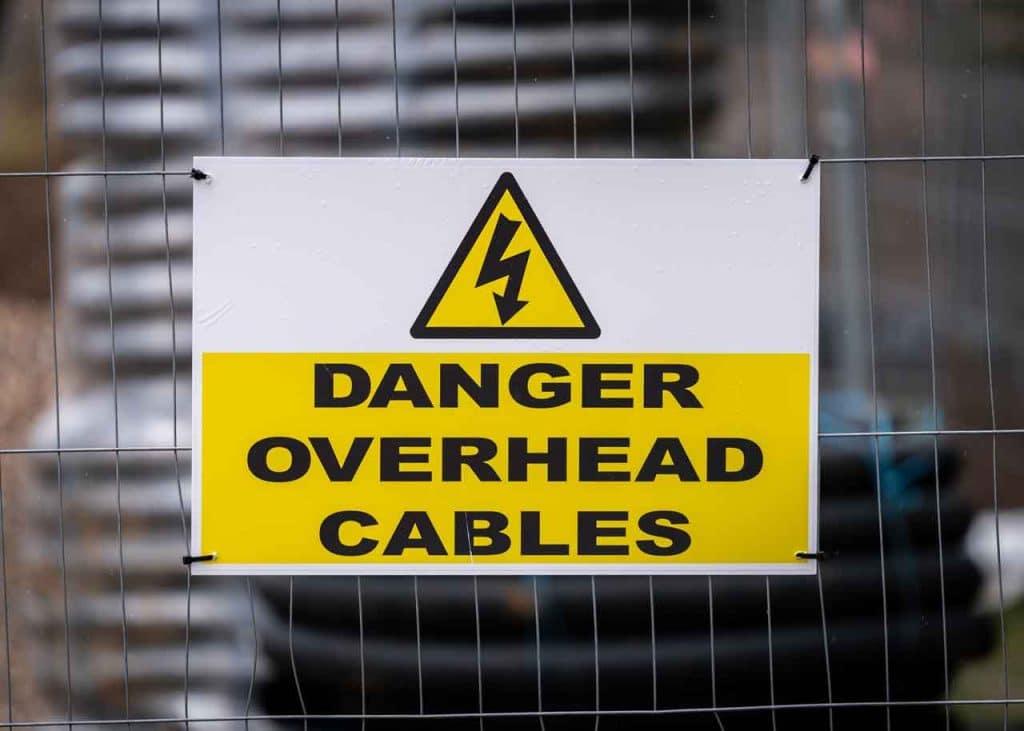

Overhead Power Lines

A common source of hazard is overhead power lines. You might think it isn’t much of an issue, but countless businesses utilize equipment like moving high-voltage cranes or lifts. Consider manufacturing scenarios or the steel industry. Heavy steel, shipping containers, and many other large items require the use of overhead cranes. Many of these run on tracks with vast amounts of electricity powering their operation.

Now consider the maintenance person who might set their ladder up to reset an overhead door motor. If the staff gets too close to live crane power (it should have been locked out in the first place), you might visit the maintenance person’s family to offer your condolences.

Overhead power lines often come into deadly situations employing lift equipment. Forklifts, scissor lifts, aerial booms, and other forms of lifting equipment may easily contact overhead power lines.

Avoidance Of Overhead Power Line Hazards

- Always have any overhead equipment locked out, powered down, and loss of power verified before engaging in any activity that involves working at heights in the vicinity of electrical power lines.

- Have staff cordon off a minimum safe distance around the lift equipment to avoid the potential for bumps caused by passing equipment such as forklifts.

- Practice formal key control for the locked-out cranes or other overhead equipment. Ensure all staff is officially clear of the entire area before re-energizing any circuits or equipment.

- Use common sense; it’s often right.

- Complete a hazard recognition assessment before beginning work. There are many situations, including concrete pumpers and scaffolding, where contact with electrical lines may be dangerous. (source)

Overloading Circuits

Because circuits are often embedded behind walls, and that circuit panels, receptacles, and equipment are often mislabelled (or not labeled at all) regarding their circuit energy source, it’s no wonder that circuits get overloaded. After all, who hasn’t blown a breaker or fuse from running the toaster and microwave simultaneously?

Overloaded circuits are no joke when it comes to commercial or industrial applications. Not that residential electrical can be any less formidable, but when big machines are involved, there is usually significant amperage as well.

Circuit overloading has been known to melt wires inside their metal conduits, sometimes going as far as causing fire or electrifying a metal EMT conduit.

Aside from the obvious labeling circuits, an intelligent plan is to map out facility circuits and ensure that your loads running on them are well under the tolerance. For example, North America’s standard residential electrical circuit is 15 amp at 110 Volts. There is a degree of variance (up to about 10%), but those are the raw numbers. Most fuses and breakers go between 12 and 13 amps, rather than the actual 15 that the circuit is said to provide.

With this in mind, it isn’t hard to overload a circuit with only a few power tools plugged in.

Running something such as an industrial press might require much higher amperage or voltage circuits. Some will even require further phases of power added to the source.

With so much of our work requiring power, it’s easy to overload circuits and create hazardous situations we may not see until it’s too late.

Try having your staff spend a few hours drawing a site map of the circuits and labeling each receptacle concerning its panel and breaker number. A little organization now can save you many headaches down the road and help you provide training for emergency power shut-off procedures for your staff.

Undersized Wiring And Cables

If a circuit in your business is damaged by something, like a forklift, it’s simple to have your maintenance staff repair the issue. However, what if staff get the wire gauge wrong and undersize the wire to the load?

Undersized wiring and cables will create more resistance due to a smaller amount of wire for the electricity to travel. If the electricity is too great for the ability of the wire to transmit it, the electricity will build up in the wire, and the wire will heat up until it melts or causes fire. Either way, undersized wire is a severe hazard if your staff are unaware of how to gauge wire to the electrical load it is intended to conduct.

Wet Conditions

You know that a toaster in a bathtub is a bad combination. So why would staff use corded power tools in wet conditions? Isn’t that sort of like a bathtub in the rain scenario? It sure is, but many businesses push their staff to work in the rain and other wet conditions when power tools are required.

If wet conditions are unavoidable, all power sources must be opened and discharged before staff enters the vicinity. Depending on the voltage, even moisture in the air might induce an arc flash. Arc flash might be as hot as 35,000 degrees Fahrenheit (19,400 degrees Celsius); it’s a form of electrical explosion that is best avoided for obvious reasons.

If you’d like to read more about arc flash and the PPE required, check out this article about arc flash equipment inspection.

Understanding the limitations of the working conditions is vital to keeping staff safe and healthy.

Always ensure staff is trained and a refresher course schedule is in practice. Utilizing tools like Toolbox Talks for your staff is one way businesses are proactively doing their due diligence to advance the health and safety of their workplaces and prevent electrical hazards from becoming incidents.