In the world of field operations management, where the unpredictable is the norm, risk management and field reporting are the dynamic duos that keep things from spiraling out of control. Risk management – the superhero of the field, needs your trusted guidance to prevail. Simultaneously we need appropriate strategies and solutions for field reporting and risk management documentation that coincide with operational requirements.

Mastering risk management relating to field operations is challenging but not impossible. Your teams can function as a single, safe, well-oiled machine with the right strategies and tools.

In this guide, we will explore risk management relating to field operations. In particular, we’ll focus on strategies for managing risk at a distance and the tools that make it possible. We will look at understanding risk management to create and implement strategies that make our jobs more straightforward and safer. Not only are we going to talk about some of the best practices, but we’re also going to introduce you to a solution that cuts your management time dramatically and makes it easier for your field teams to report in.

Field Operation Risk Management – Why All The Fuss?

Surprisingly, there are still managers working today who neglect to consider the extreme effects of incidents on people, businesses, and society. That’s why we cannot ignore what may be – our actions today reflect what happens tomorrow.

In 2020, the United States had a cost of $163.9 billion dollars for work injuries. That’s an insane number, but NSC Injury Facts don’t make these things up. That figure includes the following:

- $44.8 billion for wage and productivity losses

- $34.9 billion in medical expenses for the injured

- $61 billion in administrative expenses

Sure, the above figures are so huge that they seem almost inconsequential. If we break it down, we’re looking at the following, again according to the NSC:

- $1,100 per worker injured

- $1,310,000 per worker death

- $44,000 per medical injury requiring professional consultation

As you can see, the numbers tell us that injuries cost much more than pain and suffering – they cost a lot of money. Implementing some smart field risk management practices doesn’t seem like such a bad idea, and it’s much cheaper than dealing with an incident. Why? Because we’re not even mentioning how you pay a lot more over time once an incident occurs. For instance, do you pay insurance? Call them up and ask what your rate would be if someone dies at your work. The response is often that they won’t insure you after that, or if they do, the amount is astronomical. So, you have to consider more than the short-term costs. You have to consider long-term consequences.

Understanding Risk in Field Operations

To best determine how to manage risks in the field, we’d better define what constitutes a risk or hazard in the first place. Let’s look at how to clarify these terms best to have a strong foundation and start on the same page.

Risk

Risk refers to the probability or likelihood of an adverse event or outcome occurring due to a particular hazard. We often characterize it by the severity of the potential consequences and the likelihood of the event happening. Risk is an inherent aspect of various activities and situations and can never be eliminated, but it can be mitigated or managed through various strategies.

Hazard

A hazard is a source, condition, or situation with the potential to cause adverse effects, damage, or harm to individuals, property, or the environment. Hazards may be physical (e.g., chemicals, machinery), biological (e.g., pathogens, allergens), psychological (e.g., stress, bullying), or environmental (e.g., weather-related events, pollution). The identification and assessment of hazards are critical steps in preventing and controlling risks associated with them.

Risk Management

Risk management is the systematic process of identifying, assessing, and controlling risks arising from specific hazards. Risk management aims to minimize the likelihood and impact of adverse events while maximizing opportunities for positive outcomes.

The process of risk management typically involves the following steps:

- Risk identification

- Risk analysis

- Risk evaluation

- Risk mitigation

- Risk monitoring and review

Risk management is essential in various fields, including business, finance, healthcare, and occupational health and safety. It ensures the safety and well-being of individuals, organizations, and the broader community.

Field Operations Risks Explained

Field operations are typically riskier for team members due to a lack of oversight. However, we can flip the script around on this one if we dive deep enough into what risks pose a threat versus the probability of their occurrence.

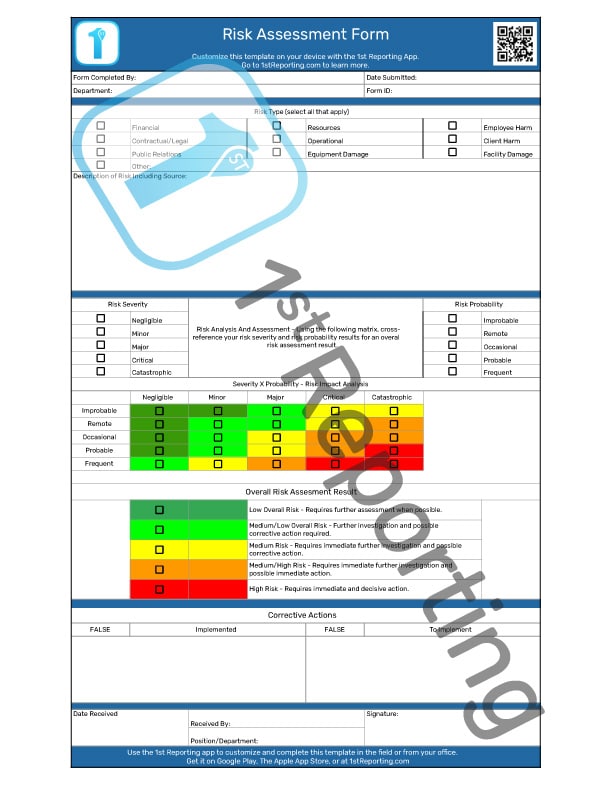

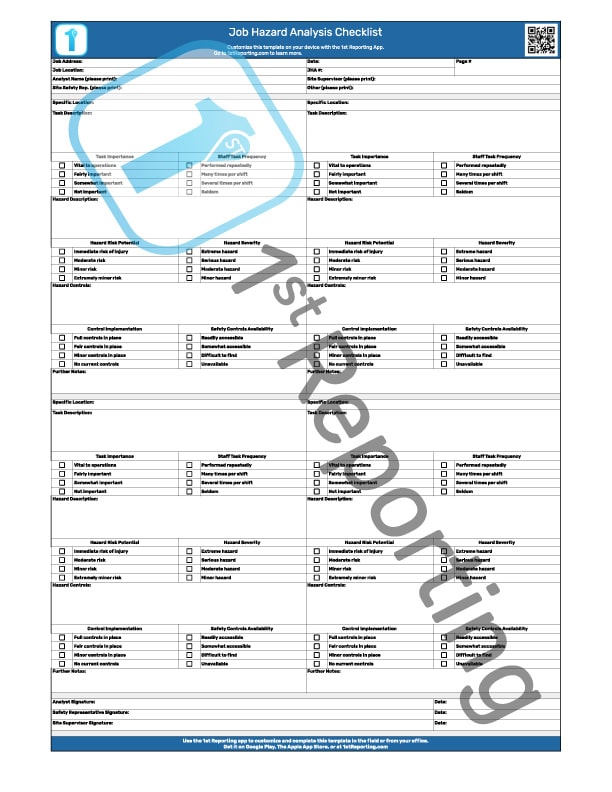

In order to achieve a refined perspective, it’s preferable to complete a risk assessment followed by a job hazard analysis for each role and hazard defined in the risk analysis. Furthermore, it’s critical to understand what these audits reveal. What they show will fall into one of three categories of risk, defined as follows:

Environmental Risks

The environmental risks include weather-related, natural hazard-related, wildlife encounters, and hazardous material exposures. Any of these sorts of hazards can seriously threaten workers on the wrong side of a situation.

Operational Risks

Operational risks typically include equipment failure, logistical or transportation risks, regulatory and compliance risks, or accidents and injuries occurring during operations. The last point could relate to jobs that see frequent injuries due to the nature of the work.

Human Factors Risks

Human error is the biggest culprit within the human risk sphere. However, human factors might also include fatigue and stress-related incidents, training or the lack thereof, or even cultural or language barriers that cause a risk. For example, team communication during an emergency is hampered by language barriers if anyone on the team has a language barrier.

Implementing a Risk Management Plan

We’ve discussed the concepts behind why you should perform a health and safety risk assessment – and you know that your teams working in remote locations ought to do the same before they start work. But how do you implement a policy that includes mandatory safety audits if you aren’t there to see it through in person? And what do we need to have in your approach to ensure all the angles are covered?

What to Include In a Risk Management Plan

The first thing to do if you need to draft a risk management plan for your field teams is to identify the steps required to complete the task. These steps will include instructions on how your team members should complete the following:

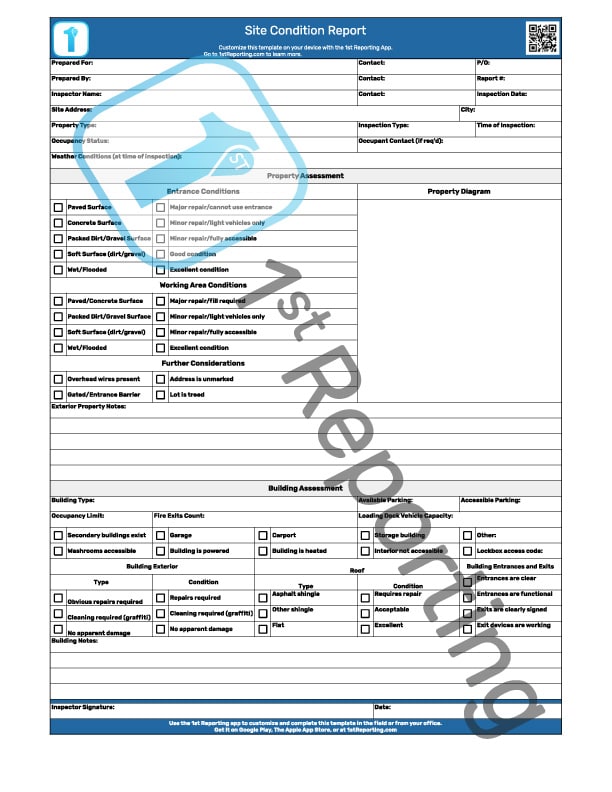

- Risk identification in the field – completing a JHA, risk assessment, and site condition report.

- Risk assessment – review the results noted in the JHA, risk assessment, and site condition report.

- Risk mitigation and control – if possible and safe, your team members should neutralize the risk. This step involves locking out sources of electrical or potential energy and possibly cordoning off an area with the appropriate signage (such as pylons, caution tape, and warning signs).

- Risk monitoring – your team on-site should watch for additional risks and hazards to ensure everyone’s safety while the risk is mitigated.

Meanwhile, back at your base of operations, you’ll need to complete a risk review of all the included documentation. That might mean you even go as far as running some custom reports to determine if there are patterns to the incident occurrence.

Stakeholder Key Objectives

All key players must understand their role in your team’s safety. For your team members to give your safety plan the attention it deserves, you’ll need to ensure clear communication regarding every role’s responsibilities relating to your safety objectives. The following is a list of key objectives that you’ll want to ensure come first and foremost in your team’s daily goals:

Enhance Risk Identification – promoting safe work practices and hazard identification is crucial to a team’s safety success and, therefore, needs to be a primary objective.

Improve Risk Assessment – ask your stakeholders to provide their context-specific experience and expertise to improve your existing risk assessment procedures.

Develop Effective Strategies – key stakeholders can help to develop effective strategies for promoting a robust internal risk management plan. Furthermore, it’s a key component of improving and enhancing the risk identification and assessment processes, so developing your strategy with the help of a stakeholder perspective is a must.

Facilitate Transparency – promoting key stakeholder objectives to include transparent communication is critical to assessing job hazards and workplace risks. Without transparent communications, your entire team is left in the dark.

Increase Accountability – Promoting honesty and accountability is critical to transforming your health and safety department into an effective incident mitigation and prevention machine.

Daily Operations

You might be wondering how you will implement pre-shift safety audits for teams located at various locations. Not to worry, we’ve got an excellent solution for daily operations audits, inspections, and even incident documentation.

Practical Tools for Managing Risk in the Field

Reporting and Communication Tools (In-One)

Problem: How to manage safety protocol at a distance.

Solution: Implement a robust platform that allows team members to communicate and relay safety and risk assessments to you or another appropriate supervisor.

Sounds too good to be true? I assure you, it is accurate, and we call it 1st Reporting. But more about that in a moment. First, let’s break down the sort of tools you and your team need, so we can understand the best type of platform you can use to make it all happen.

To complete appropriate risk management, your team must act as your eyes and ears on-site. Furthermore, they require training and some form of documentation to follow and write down or record their observations.

Next, your team will need a means of relaying information gathered back to you or the appropriate supervisor at your organization. You or another supervisor will need to review the observations noted by your team member in the field. Following said review, you’ll need to decide how to proceed.

Assuming your organization already has a health and safety manual/policy, detailed with JHA’s and such information, isn’t reviewing each situation a little redundant? If parameters are set, can we not allow automation to help us? After all, we’re living in the age of information, and computers do so much already. Let’s have them do a little more.

Utilizing technology, you can implement a system like the 1st Reporting app. Within the app, you’ll find various safety checklists, site reports, JHA templates, and more, all of which are at your disposal within the app. Similarly, the application has a built-in template builder so that you can create custom forms, checklists, and more.

Okay, you probably think what I’ve mentioned isn’t a big deal, but that’s only the tip of the iceberg. The app lets you assign team members to groups and assign specific forms or templates to those groups, giving you control over the process documentation you want your teams to use. Furthermore, you can set up custom notifications, so when a team member in the field completes a report (like a site condition report, for example), you could receive (or have another appropriate manager receive) a notification.

You’ll know the moment your team member completes their audit. And therefore, you’ll be able to monitor risks within seconds of your team completing a report. In other words, you’ll know about the report before your team member can call you to tell you they finished it. The app increases your ability to respond to reports, whether they are emergency incident reports or minor inspection reports. You will have complete control, and the customizable map view on your report manager’s dashboard within the app means that you can also visually see where all report completion occurred – right on a map.

With the ability to dynamically link reports, you can imagine what you could do to create a customized reporting experience that is suited to your organization’s needs. The straightforward template builder and app dashboard make it easier to replace old, unreliable paper reports with all their handwriting issues, smudges, and other issues that come with that ancient technology.

Okay, I don’t want to oversell here, but you need to know that the app is not only mobile. It works with Android and iOS devices (you can find it on Google Play or The Apple App Store), works on laptops and desktops, and is even compatible with Microsoft Teams®. Furthermore, the application records inputs to the forms locally, so if the device is away from a signal, the input information your team member includes isn’t lost like a piece of paper in the wind. Once the device reconnects to the internet, it merely uploads the team member’s input information to the secure cloud. You’ll never lose a report again. It is groundbreaking, so it’s fast becoming the industry standard.

You know the need for safety and risk management and know the best tool. But let’s discuss more what you may not know regarding ensuring compliance with regulations and municipal standards.

Ensuring Compliance with Regulations and Standards

Many countries worldwide follow the standards of several independent organizations that have made a name for themselves in their respective industries in their home countries and abroad. However, to clarify, I’ve created a convenient breakdown of the major players in North America, so you’ll have the tools you need to find specific standards and recent regulations. Feel free to bookmark this page so you can easily reference it again.

Canada

Many of the regulations in Canada revolve around one of two primary means of management: Federal and Provincial. In Canada, it’s one or the other for most industries, but some have the privilege of answering to both. Here is a list of convenient links to regulatory bodies and regulations for Canada that you’ll find necessary.

- Provincial Occupational Health and Safety Regulations: Each province and territory in Canada has its own occupational health and safety legislation and regulatory bodies that establish and enforce standards to ensure employees’ safe and healthful working conditions. Key standards relevant to field operations include personal protective equipment (PPE), hazard communication, confined spaces, fall protection, and machinery and equipment safety.

- Canadian Centre for Occupational Health and Safety (CCOHS): CCOHS provides guidance and resources on occupational health and safety topics, including those relevant to field operations, such as workplace hazards, ergonomics, and chemical safety.

- Canada Labour Code: The Canada Labour Code establishes occupational health and safety standards for federally regulated workplaces in Canada. Part II of the Code addresses occupational health and safety and is relevant to field operations under federal jurisdiction.

- Transport Canada Regulations: Transport Canada oversees the regulation of the transportation of dangerous goods (TDG) in Canada. The Transportation of Dangerous Goods Act and its regulations outline requirements for the packaging, labeling, handling, and shipping of hazardous goods.

- Canadian Environmental Protection Act (CEPA): CEPA is a federal law protects the environment and human health from risks posed by pollutants and hazardous substances. CEPA regulations are relevant to field operations involving using, storing, or disposing of hazardous materials.

- Canadian Standards Association (CSA) Standards: CSA develops and publishes standards that apply to various industries and aspects of field operations. For example, CSA Z462 addresses workplace electrical safety, and CSA Z94.3 covers eye and face protectors.

- Industry-Specific Standards and Regulations: Certain industries in Canada have their specific standards and regulations. For example, the oil and gas industry has standards set by the Canadian Association of Petroleum Producers (CAPP), and the mining industry is subject to regulations from provincial mining regulatory bodies.

The United States

Below you’ll find a series of government agencies that manage and oversee many aspects you’ll encounter when managing field operations in various industries.

- Occupational Safety and Health Administration (OSHA) Standards: Under the US Department of Labor, OSHA establishes and enforces standards to ensure safe and healthy working conditions for employees. Key standards relevant to field operations include personal protective equipment (PPE), hazard communication, confined spaces, fall protection, and machinery and equipment safety.

- National Fire Protection Association (NFPA) Standards: NFPA develops standards and codes related to fire and life safety, some of which apply to field operations. For example, NFPA 70E addresses electrical safety in the workplace, and NFPA 30 covers flammable and combustible liquids.

- Environmental Protection Agency (EPA) Regulations: EPA regulations address environmental protection and impact, including the handling, storage, and disposal of hazardous waste (Resource Conservation and Recovery Act – RCRA), air emissions (Clean Air Act), and water pollution (Clean Water Act). These regulations are relevant to field operations involving hazardous materials or environmental impacts.

- Department of Transportation (DOT) Regulations: The DOT regulates the transportation of hazardous materials (hazmat) to ensure safety during transit. The Hazardous Materials Regulations (HMR) outline requirements for packaging, labeling, and shipping hazardous materials.

- American National Standards Institute (ANSI) Standards: ANSI oversees the development of voluntary consensus standards in various industries, including some that apply to field operations. For example, ANSI Z359 addresses fall protection, and ANSI Z87.1 covers eye and face protection.

- American Petroleum Institute (API) Standards: For field operations in the oil and gas industry, API develops standards and recommended practices covering various aspects, including good construction, drilling operations, pipeline safety, and equipment integrity.

- American Industrial Hygiene Association (AIHA) Guidelines: AIHA develops guidelines for industrial hygiene and occupational health, which may apply to field operations involving exposure to hazardous substances, noise, or ergonomic risks.

- Mine Safety and Health Administration (MSHA) Regulations: For field operations in the mining industry, MSHA enforces regulations to protect miners’ safety and health, including standards related to ventilation, electrical systems, and ground control.

Audit Compliance and Inspection Frequency

If you want to avoid heavy fines, penalties, and, more importantly, incidents involving injuries, then you need to ensure that your organization completes regularly scheduled safety audits. Furthermore, it’s not a bad idea to have some unscheduled inspections either. Keeping your team on their toes regarding safety is a great way to improve overall safety, whether at your base of operations or a remote job location.

Some inspections, like those conducted on self-propelled vehicles or other equipment, have set mandatory schedules controlled by regulation makers. For example, in Canada, you must have forklift trucks inspected annually if used at a place of business. Some provinces go as far as Ontario in saying that a pre-shift inspection by the operator is mandatory by law. Similarly, vehicle operators must complete the same daily or pre-shift vehicle inspection. They must carry a copy of the review for 30 days, and you must maintain a copy in the office.

The point of this is that you need to comply with local regulations and ensure that the equipment, facilities, and any other item that may pose a risk are managed appropriately. Appropriate management includes regular inspections to ensure safety practices are in place and adequately used by team members.

Most countries, Canada and The United States, by no means being exceptions, require that businesses maintain documentation of safety inspections. Those required by law are absolutely required, but keeping all of your inspections, audits, risk assessments, and job hazard analysis on file for the prescribed minimum period is a great idea. In many places, that minimum is as small as seven years or as long as decades. The length of time you must maintain safety documents depends on the document type, the severity of the situation, and the regulations in your region or country.

Responding to Incidents and Emergencies

The Emergency Response Plan

Within your health and safety manual, you’ll need to include an Emergency Response Plan (ERP) as a part of the incident or risk mitigation. You can use an Emergency Action Plan Checklist (EAPC) to help create that portion of your health and safety policies manual. Furthermore, including a copy of your EAPC in the appropriate JHAs will save you headaches regarding proper training for related roles and responsibilities.

Ensuring you have a complete ERP will aid your team members in following the proper procedures when responding to incidents and emergencies. However, depending on the nature of your industry, there may be an exorbitant amount of safety protocols. Perhaps your industry has high turnover rates, so new and ‘green’ staff are always an issue for safety managers. Either way, you may find that using a Procedural Checklist with a solution like 1st Reporting helps solve this issue. Let me explain how.

Using a procedural checklist to respond to emergencies is a smart way to ensure the appropriate steps are taken and in order. Take a situation where a team member is injured. You could train your team to follow a Procedural Checklist for Injury-Related Incidents that helps your responders take the appropriate action step by step, thereby avoiding the escalation of incidents by negligent or ignorant reactions.

Fire Drills and Emergency Preparedness

One of the best ways to appropriately respond to incidents and emergencies is through practice. They say practice makes perfect, and I’m sure every professional will agree that you need to practice a lot to get good at something. So, when a life or death incident or emergency presents itself, why do we feel the need to not prepare for such eventualities?

Pro Tip: When running emergency preparedness scenarios, make the management process more straightforward with a fire drill checklist. You can use it right on the 1st Reporting app to efficiently complete a fire drill while on the move with your smart device. Now that’s what I call taking the fire drill to the next level. Want more information? Try reading our guide to preparing fire drill procedures.

Record, Review, Reflect, and Resolve

At 1st Reporting, we take the 4-R rule seriously. The rule is an action plan for dealing with incidents and risk management effectively:

- Record – Record and document risks, hazards, incidents, and observations.

- Review – Review all documentation to get perspective on the incident or risk.

- Reflect – Consider the many ways in which you could:

- Prevent incident or risk recurrence

- Mitigate future recurrences

- Improve current processes/equipment/facilities

- Resolve – Using the ideation process results from step 3, take appropriate action to resolve any risk-creating issues to avoid recurrence or possible incidents.

Following these steps will help your organization deal with any incident, risk, or hazard potential. However, ensure you comply with local regulations and don’t miss anything vital.

Maintaining and Updating the Risk Management Plan

I’d like to take a moment to reflect upon the last 3 ‘R’s’ from our 4-R rule mentioned above. It cannot be oversold how critical the review, reflection, and resolution process is. I mean, documenting risks is one thing, but figuring out how to prevent them from being risks in the first place is something else entirely. That’s why reviewing, re-review, and updating your risk management plan and strategy is essential.

Integrating your risk management process into your team’s day-to-day operations is the first step to ensuring you have a solid foundation to build from. After all, you can’t maintain or manage a risk management process or program without buy-in from your team.

Including your risk management platform (like 1st Reporting) in the daily operations of your team members will mean that you have fundamental buy-in by way of your team doing their regular duties. Furthermore, you can use the application to enforce safety policies by setting up forced fields within procedural checklists. That is, your team members cannot proceed until they complete the step you deem mandatory. Using procedural checklists in this way can allow you to manage every aspect of your team’s daily operations, whether you are on-site or not.

Continuous safety improvement is the goal, with minimal to no recurrence of hazards or incidents due to your robust risk management practices and policies. Using appropriate tools like 1st Reporting only makes it much easier to improve your operational processes continuously. After all, a digital and customizable form platform is much easier to change than paper forms printed and sent out to your various teams in the field. Furthermore, if your teams work in highly remote locations, managing the logistics of something as simple as a form or checklist update might be challenging.

With the ever-changing current technology, it just doesn’t make sense to stick with paper and the issues related to its use. Use paper when the government body accepts nothing less. Use a digital platform like 1st Reporting for everything else. It makes risk management more straightforward. Sign up for 1st today and find out what you’ve been missing out on (and get more of your time back for more essential things).