Ensuring your organization complies with regulatory requirements regarding fire extinguishers is more important than many think. Good fire prevention practices aren’t just innovative – they save lives. That’s why we’ve put together this convenient guide for managing fire prevention, particularly fire extinguishers, for you today.

Fire extinguishers are a required component of an active fire prevention system. However, having the appropriate type, number, and placement of fire extinguishers within your workplace is critical.

To ensure compliance and maximum fire prevention safety, follow this guide and local regulations to complete your fire prevention program. So, please feel free to bookmark this guide to easily return and use it to train your team members on fire extinguisher management and care basics.

Types And Classes Of Fire Extinguishers

As you know, there are different fire extinguishers; but did you know that there are different types of fires? So, extinguishers have specific classes that match the fire. Each type has a specific purpose, and using the wrong type can cause immediate and severe hazards. For example, using a water-based fire extinguisher on an electrical or grease fire is very bad because it could cause electrocution or the spread of fire. But do you know each fire extinguisher type’s purpose? Here’s the information you need to ensure you and your team are using the correct classification of extinguishers.

Fire Extinguisher Classes

Fire extinguishers have a specific classification of use. Many fire extinguishers are useful for more than one type of fire, but some can cause the fire to spread, depending on the fire type. Therefore, it’s essential to understand the basics. Here’s a table showing the fire class, the associated symbol and color for the class, the typical fire extinguisher fill type, a description of use, and example combustibles.

| Class of Fire | Symbol and Associated Color | Typical Fire Extinguisher Fill Types | Description of Use | Example Combustibles |

| A |  | – Water | For ordinary combustibles. | – Wood – Paper – Cloth |

| B |  | – Ammonium – Phosphate – Halogenated Agents – Film-Forming Foams – CO2 | For flammable or combustible liquids and gases. | – Alcohol – Lacquer – Petroleum – Grease |

| C |  | – CO2 – Mono Ammonium Phosphate – Potassium Bicarbonate – Potassium Chloride | For energized electrical fires. | – Appliances – Electrical cords – Old building wiring |

| D |  | – Powdered Graphite – Granular Sodium Chloride – Granular Copper-Based | For combustible metals. | – Lithium – Potassium – Magnesium |

| K (Class F in Europe) |  | – Potassium Acetate – Potassium Citrate – Potassium Carbonate | For flammable cooking oils and greases. | – Deep fryers (with oil) – Stovetop cooking oils – Cooking grease |

It’s noteworthy to consider the difference in fire classification between North America and Europe. In North America, we follow the NFPA and its classification system. In Europe, the classification works a little differently. Most European nations classify fires by the reactivity of the material experiencing combustion. Here’s a basic table showing how the European fire rating system works:

| Reactivity Class | Material Reactivity Performance | Scenario | Heat Reactivity | Example Materials |

| A1 | No contribution to fire. | Fully developed fire in a room. | At least 60kW/m2. | Products of natural stone, concrete, bricks, ceramic, etc. |

| A2 | No contribution to fire. | Fully developed fire in a room. | At least 60kW/m2. | Products are similar to A1, including small amounts of organics. |

| B | Extremely limited contribution to fire. | Single burning item in a room. | 40kW/m2 in a limited area. | Gypsum boards (thin surface material) and fire retardant wood products. |

| C | Limited contribution to fire. | Single burning item in a room. | 40kW/m2 in a limited area. | Gypsum boards (thick surface material). |

| D | Acceptable contribution to fire. | Single burning item in a room. | 40kW/m2 in a limited area. | Wood products greater than 10mm thick and density of 400 kg/m3 or greater. |

| E | Acceptable contribution to fire. | Small flame attack. | Flame height of 20 mm. | Low-density fibreboard and plastic-based insulation products. |

| F | No performance requirements. | – | – | Products not tested. |

Fire Extinguisher Types

As you are aware of the different classes of fire, let’s talk about the fire extinguisher types. It’s important to note that depending on where you live and whom you’re talking to, fire extinguisher types may be more than a little confusing. For example, you can have a fire extinguisher that you can use on more than one fire type. So, a fire extinguisher might display an A-B-C type or other similar combination of the five primary classifications in the above table. Similarly, you might see an A-B labeled fire extinguisher, displaying that it is effective against both types A and B of fire.

TTE: Time to empty. This time describes the typical time you have to get the fire out before the extinguisher is empty and, therefore, no longer a viable fire prevention tool. Larger extinguishers may provide greater TTE values. These values concern the standard-sized fire extinguishers in Canada and the United States of America.

CO2

Carbon dioxide is an excellent fire stop for two reasons. First, fire needs oxygen, so the CO2 extinguishers do a great job choking the fire. Second, as the pressurized CO2 is released from the extinguisher nozzle, it rapidly expands, pulling energy from the surrounding environment. The result is that it’s pretty cold. So, not only does it choke the fire, it super-chills it at the same time. It’s nowhere near as drastic as liquid nitrogen, but it still cools things off nicely.

Typical Extinguisher Range: Short

Active Use TTE: 8-30 seconds for a 10-15 pound device (source)

Dry Chemical

Dry chemical fire extinguishers primarily find use against various fires and often receive classifications like A-B-C. The filler is usually mono ammonium phosphate, which appears as a fine yellow powder when expelled from a fire extinguisher. These extinguishers use pressurized nitrogen gas as the propellant. These extinguishers are most commonly used in workplaces due to their versatility in fighting multiple fire classes.

Typical Extinguisher Range: Moderate

Active Use TTE: 10-25 seconds (source)

Dry Powder

Dry powder fire extinguishers are very similar to dry chemical extinguishers, and often people confuse the two. However, they are different in the materials used and in the types of fires they fight. For example, dry powder extinguishers fight combustible metal fires (D class), whereas dry chemical extinguishers fight class B or C fires. Understanding the difference between the two types of fire extinguishers is crucial because a dry powder fire extinguisher will be ineffective against fires of other types.

Typical Extinguisher Range: Short

Active Use TTE: 18.5 seconds for a 6 Kg extinguisher (source)

Aqueous Film-Forming Foam (AFFF)

Typical AFFF extinguishers work on class A and B-type fires. However, there are exceptions depending on the manufacturer’s chosen fill types. The AFFF work by spraying a foaming agent that froths on top of everything it touches, which creates a barrier and smothers the fire. These extinguishers can make a mess, so be prepared for a big cleanup job if one is discharged.

Typical Extinguisher Range: Moderate

Active Use TTE: 5-10 seconds for a 1 Litre device (source)

Halogenated Agent

Halon extinguishers are no longer in production due to the halon damage to the ozone. In fact, they were phased out back in January of 1994, according to the EPA. However, in the aviation industry, you can still find halon extinguishers, and there are some modern alternatives as well, namely 3M™ Novec™ 1230 Fire Protection Fluid and FM-200™.

Typical Extinguisher Range:

Active Use TTE: 5-25 seconds (source)

Water

Water needs little to no explanation. The water is pressurized in the fire extinguisher, so it has a decent range compared to other extinguishers. However, you can’t use a water extinguisher on oil, grease, electrical, and most metal fires, too, due to the explosive nature of metals and water reacting together at high temperatures. However, a water extinguisher works great if you have an A-class wood or similar fire.

Typical Extinguisher Range: Long

Active Use TTE: 50-60 seconds (source)

Wet Chemical

Wet chemical extinguishers typically use misted potassium as their means of combatting fire. They work well against cooking oil fires and similar high-temperature oil-based fires. They are effective because, unlike their dry chemical counterparts, they also cool an area, which is highly important in combating grease and oil fires.

Typical Extinguisher Range: Moderate

Active Use TTE: 30-85 seconds (source)

Regulations For Workplace Fire Extinguishers

Many countries follow the NFPA standards for fire prevention. However, the number of fire extinguishers in a workplace may fall under the jurisdiction of a local regulatory authority in your region. Therefore, it’s critical to find out from a local authority what the prescribed minimum is in your area and for your industry. However, you can follow some basic rules to get things rolling. Here are some commonalities we find in regulations across many regions.

- Any service or work vehicle (motorized handling equipment) that transports anything flammable must have an appropriately rated fire extinguisher. It should be accessible to the vehicle or equipment operator.

- One fire extinguisher per 25 meters or 75 feet within a facility. Every fire extinguisher must be no more than 75 feet apart in a facility with normal flammables. In higher flammable containment situations, the distance between fire extinguishers in the facility decreases. For example, a fire extinguisher no more than 30 feet away from any given point is a good place to start in commercial kitchens.

- Fire extinguishers must be easily accessible and have some sign or prominent indicator. In simple terms, you shouldn’t be able to miss it in the room.

- Fire extinguishers must be located in or adjacent to exit halls or corridors. So, you’ll need a fire extinguisher for every exit and within the facility based on the flammability of contents. That’s why it’s good to consult a local authority because the flammability of contents is often questionable and requires a professional opinion of a local regulation enforcement official.

- Fire extinguishers should face monthly inspections and possess a tag indicating the last inspection date. Similarly, fire extinguisher testing, like hydrostatic testing and recharge, should occur at the prescribed times. Hydrostatic tests must occur every five years, depending on the cylinder type. Furthermore, annual testing and recharging of fire extinguishers are required in most jurisdictions for non-residential premises.

- Fire extinguishers must be replaced or recharged following use.

Fire Extinguisher Employee Training

Training means more than just showing your team how a fire extinguisher works. Team members should receive the appropriate training in the following six areas relating to fire and fire extinguishers. Please keep in mind this is a minimum training recommendation for most industries. Highly flammable material handling and other instances require much more elaborate and specific training. However, in many situations, these six items fulfill the basis of a strong fire prevention training program.

- Fire extinguisher use.

- Fire extinguisher types and when to use each.

- Hazard recognition and job hazard awareness.

- Fire and potential fire incident reporting.

- Emergency fire procedures.

- Evacuation protocol.

Implementing these six areas of fire prevention training is easy to include in your training protocol with the appropriate tools for documentation. After all, you’ll need to maintain training records, so immediately, there is a need for a training tracker. Our application, 1st Reporting, works well in this regard because you can set up a training tracker and use the application to document everything from fire evacuation checklists to job hazard awareness reports. It works best for all situations requiring documentation in a report, checklist, or other form types. Given the customizable nature of our form builder, you can use the app to create and complete just about any form you can think of, while the mobile nature of the app allows you to get it on all of your team’s smartphones, laptops, or other devices. We’ll talk more about how our application will help you with so many different reporting of incidents, inspections, and other situations.

Inspecting, Maintaining, and Recharging Fire Extinguishers at Work

As mentioned earlier, in most jurisdictions, regulations stipulate that a workplace fire extinguisher should receive monthly inspections, annual testing, and hydrostatic testing as prescribed by the extinguisher cylinder type. Similarly, we mentioned fire extinguishers must possess a tag that clearly states the last inspection and testing dates. In greater detail, let’s talk about the tests and audits of fire extinguishing equipment (portable).

Monthly Inspections

Monthly inspection of fire extinguishers is important for a few reasons. First, it enables you to confirm the quantity and location of extinguishers, ensuring that none are obstructed, missing, or discharged. Next, it provides a means of confirming the next required annual or hydrostatic testing.

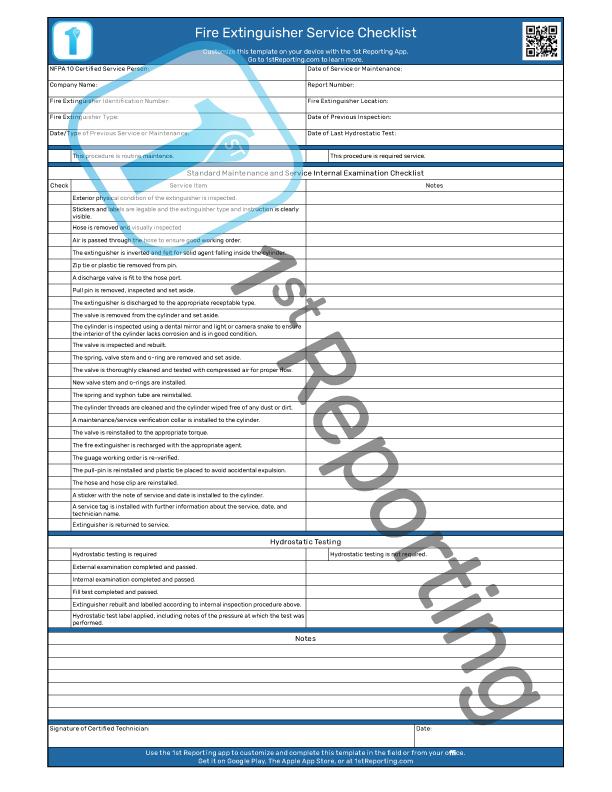

Requirements: Document each monthly inspection using a Fire Extinguisher Inspection Checklist. Maintain your inspection checklist and notes in a file if authorities require a review. Furthermore, note on the fire extinguisher’s tag the date and name of the inspector. This method maintains a double notation method, with a tag and inspection checklist providing proof of inspection.

Annual Testing

Annual testing of fire extinguishers typically takes a third party to come in and perform the tests. Most fire prevention service companies will provide ‘loaner’ fire extinguishers for typically several days to a week before they return with your tested and recharged extinguishers.

Requirements: Consult a fire prevention service for scheduling your annual testing. The test typically involves the company emptying the extinguisher, performing maintenance to the ejection assembly, and recharging the extinguisher. You’ll need to maintain records of these annual fire extinguisher inspections.

Hydrostatic Testing

Hydrostatic testing is a special test that involves emptying the extinguisher and testing the cylinder under pressure. The test looks for leaks and the overall ability of the cylinder to maintain pressured states. The hydrostatic test requires special testing equipment, so a third-party test facility is a must.

Requirements: Depending on the type of extinguisher, every 5 or 12 years. See the table in our extinguisher inspection guide with a downloadable checklist for more information.